Cooling water waste heat direct-air cooling type high back pressure-steam extraction integrated heat supply system

A combined heating and high back pressure technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve the problem of large amount of residual heat in auxiliary circulating cooling water, unsuitable for long-distance heating, and unfavorable energy saving Reduce consumption and other issues to achieve the effect of improving thermal efficiency and thermal economy, reducing losses and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

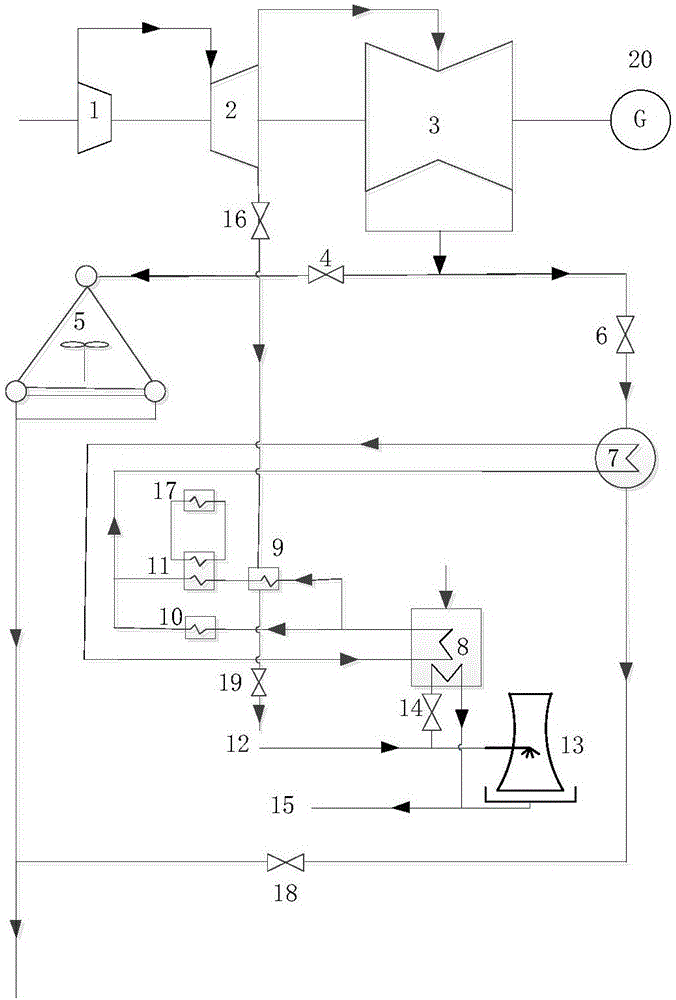

[0014] In order to solve the problem of limited heating distance in the direct supply mode of high back pressure and low temperature water, and large water loss in the heating network simply using steam extraction, the present invention provides a high back pressure-extraction combined heating system using the waste heat of cooling water for direct air cooling . The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] attached figure 1 It is a schematic structural diagram of a high back pressure-extraction combined heating system, such as figure 1 As shown, it includes air-cooling unit, first exhaust valve 4, air-cooling island 5, second exhaust valve 6, heating condenser 7, electric heat pump 8, heating network heater 9, short-distance heat users 10, heat exchange Station 11, auxiliary machine circulating cooling water outlet pipe 12, mechanical ventilation cooling tower 13, hot water valve 14, auxiliary machine circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com