Vapor condensed water recycling process and device for organic amine desulfurization system

A technology of steam condensate and desulfurization system, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of inability to use directly, waste of condensate heat energy and condensate water, and high condensate temperature, so as to achieve reuse , The cost of water production is reduced, and the condensation effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

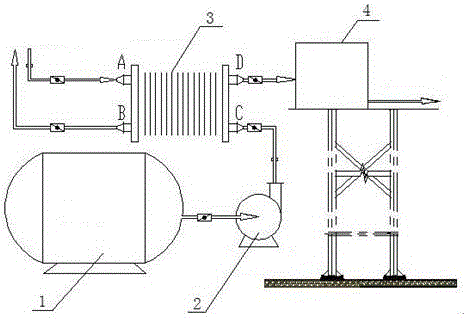

[0019] refer to figure 1 : a kind of organic amine desulfurization system of the present embodiment uses steam condensed water recycling process, comprises the following steps:

[0020] After the waste heat steam is utilized by the reboiler of the desulfurization and desorption system, it becomes high-temperature condensed water and enters the steam condensed water tank 1, and then is pumped to the heat exchanger through the condensed water delivery pump 2 to reduce the temperature of the condensed water to 30°C;

[0021] The condensed water passing through the heat exchanger enters the low-temperature condensed water tank 4 for storage, and part of the condensed water in the low-temperature condensed water tank 4 is sent to the ion exchange purification system for use, and the surplus part overflows to the soft water tank and is sent back to the water station for reuse.

[0022] The heat exchange area of the heat exchanger is 10m 2 , the water output of the condensate deli...

Embodiment 2

[0028] The difference with embodiment 1 is:

[0029] The steam generated by the main desulfurization system enters the steam condensed water tank 1, and then is pumped to the heat exchanger through the condensed water delivery pump 2 to reduce the temperature of the condensed water to 30°C;

[0030] The heat exchange area of the heat exchanger is 16m 2 , the output of the condensate delivery pump 2 is 10m 3 / h, the diameter of the refrigerant port is 65mm, and the flow rate is 36 m 3 / h.

[0031] Others are with embodiment 1.

[0032] By adopting the process and device for recycling steam condensed water used in the organic amine desulfurization system of this embodiment, the amount of water produced from desalted water can be reduced by 72,000 tons / year, the cost of water production can be reduced by 835,200 yuan, and the recovery of steam condensed water can reach 72,000 tons / year year.

Embodiment 3

[0034] The difference with embodiment 1 is:

[0035] The steam generated by the main desulfurization system enters the steam condensed water tank 1, and then is pumped to the heat exchanger through the condensed water delivery pump 2 to reduce the temperature of the condensed water to 30°C;

[0036] The heat exchange area of the heat exchanger is 21m 2 , the output of the condensate delivery pump 2 is 15m 3 / h, the diameter of the refrigerant port is 80mm, and the flow rate is 54 m 3 / h.

[0037] Others are with embodiment 1.

[0038] By adopting the process and device for recycling steam condensed water used in the organic amine desulfurization system of this embodiment, the amount of water produced from desalted water can be reduced by 108,000 tons / year, the cost of water production can be reduced by 1,252,800 yuan, and the recovery of steam condensed water can reach 108,000 tons / year year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com