Thermosensitive time indicating device

A time-indicating and heat-sensitive technology, which is applied in the direction of measuring devices, measuring heat, instruments, etc., can solve the problems that the seal cannot be too small to operate, the structure of the heat-sensitive time indicating device is complex, and it is unfavorable for the miniaturization of the heat-sensitive time indicating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

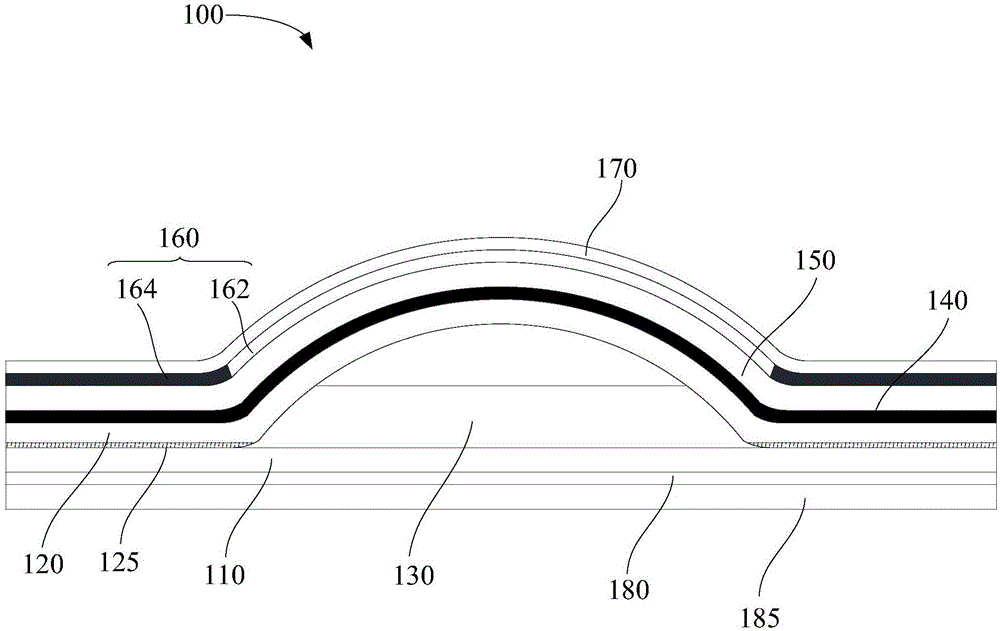

[0061] The structure of the thermal time indicating device of embodiment 1 is as follows figure 1 As shown, the base layer 110, the first substrate layer 120, the volatile function layer 130, the adsorption indicating layer 140, the second substrate layer 150, the comparison layer 160, the protective layer 170, the adhesive layer 180 and the release layer 185.

[0062] The material of the base layer 110 is PET, and the thickness is 0.18 mm. The material of the first substrate layer 120 is LDPE, and the thickness is 0.18 mm.

[0063] The volatile functional layer 130 is a phase change material. The phase change material is 2g of paraoleic acid.

[0064] The adsorption indicating layer 140 includes an adsorbent and an indicating composition adsorbed on the adsorbent. The material of the adsorbent is a polytetrafluoroethylene microporous membrane with a thickness of 0.15 mm, and the average pore diameter of the micropores of the adsorbent is 10 nm. The indicating composition includes ...

Embodiment 2

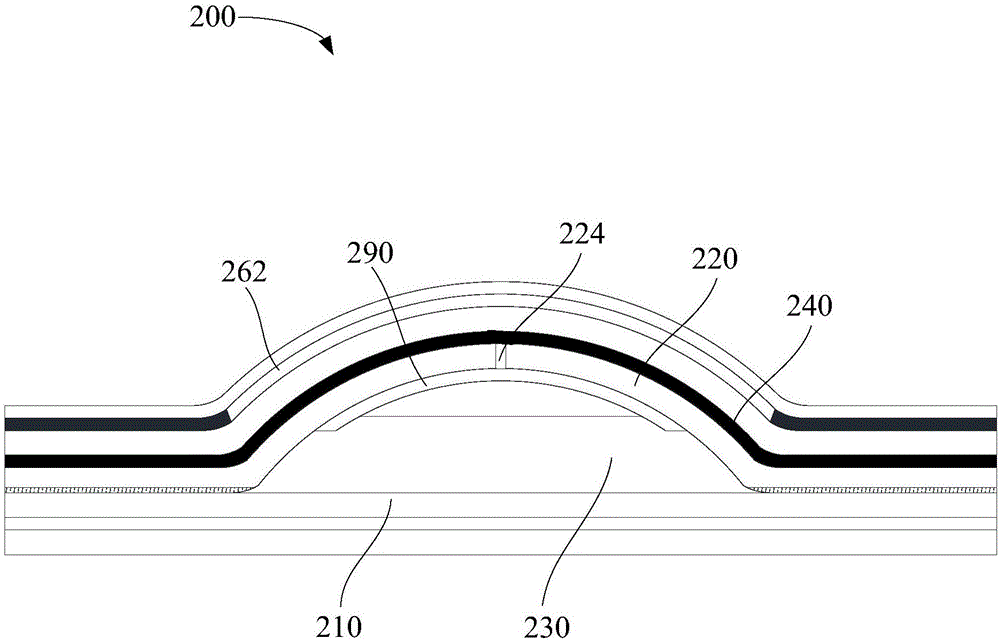

[0071] The structure of the thermal time indicating device of embodiment 2 is as follows figure 2 As shown, the base layer 210, the first substrate layer 220, the volatile function layer 230, the through holes 224, the liquid barrier layer 290, the adsorption indicating layer 240, the second substrate layer 250, the comparison layer 260, the protective layer 270, the glue Adhesive layer 280 and peeling layer 285.

[0072] The material of the base layer 210 is PET, and the thickness is 0.18 mm. The material of the first substrate layer 220 is LDPE, and the thickness is 0.18 mm.

[0073] The volatile functional layer 230 is a phase change material. The material of the adsorbent is 80g writing paper, and the phase change material is 10g elaidic acid.

[0074] The through hole 224 is provided at the center of the first substrate layer 220 and has a diameter of 0.5 mm.

[0075] The material of the liquid barrier layer 290 is a microporous polytetrafluoroethylene film with a thickness of...

Embodiment 3

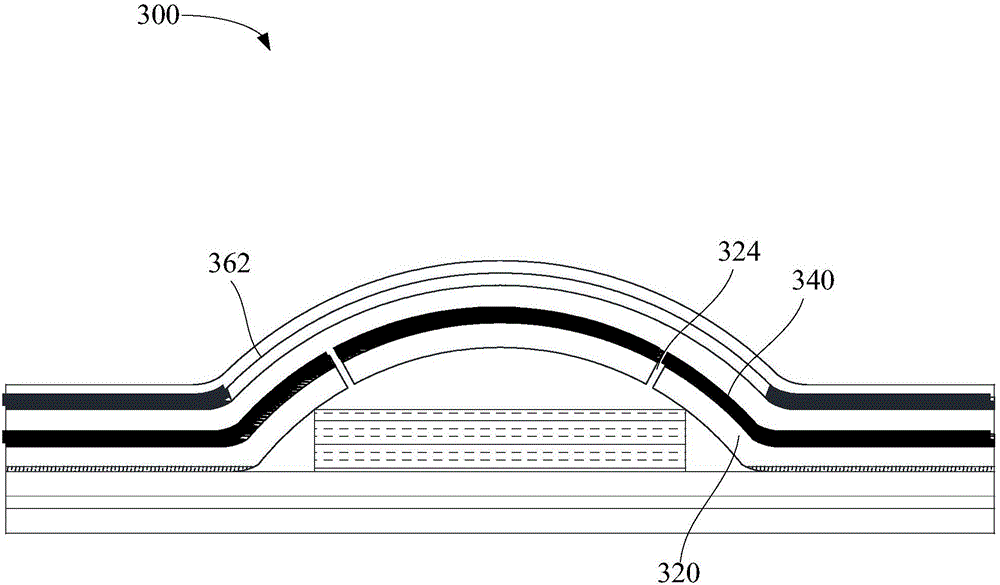

[0083] The structure of the thermal time indicating device of embodiment 3 is as follows image 3 As shown, the base layer 310, the first substrate layer 320, the volatile functional layer 330, the through holes 324, the adsorption indicating layer 340, the second substrate layer 350, the comparison layer 360, the protective layer 370, the adhesive layer 380 and the peeling Layer 385.

[0084] Wherein, the material of the base layer 310 is PET, and the thickness is 0.18 mm. The material of the first substrate layer 320 is LDPE, and the thickness is 0.18 mm.

[0085] The volatile functional layer 330 includes an adsorbent and a phase change material adsorbed on the adsorbent. The material of the adsorbent is 80g writing paper, the thickness is 0.2mm, and the average pore diameter of the adsorbent is 1μm. The phase change material is 5 g of pelargonic acid.

[0086] The adsorption indicating layer 340 includes an adsorbent and an indicating composition adsorbed on the adsorbent. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com