Measurement device of thermal performance of paraboloid groove type solar thermal collector and thermal performance prediction method

A trough type solar energy and trough type heat collector technology, which is applied in the direction of measuring device, machine/structural component testing, instrument, etc. Physically meaningful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

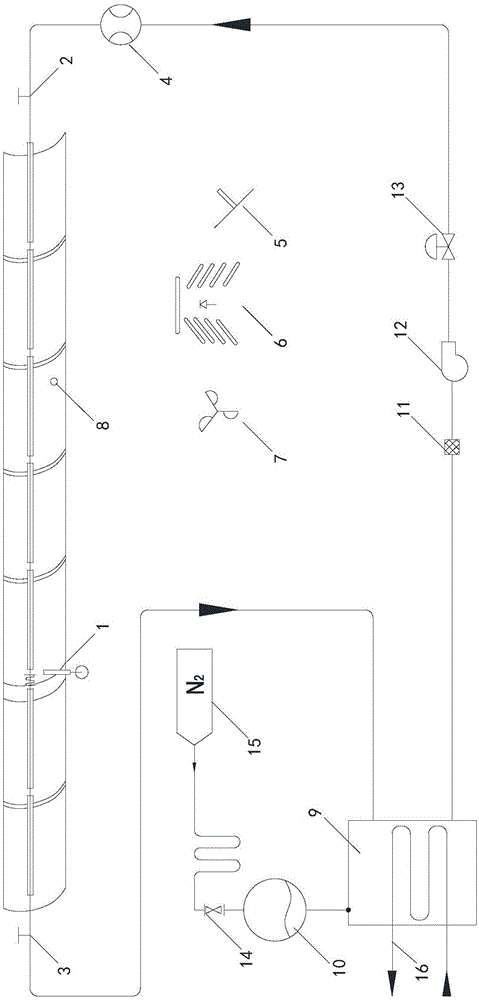

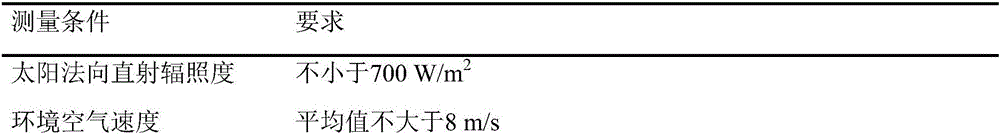

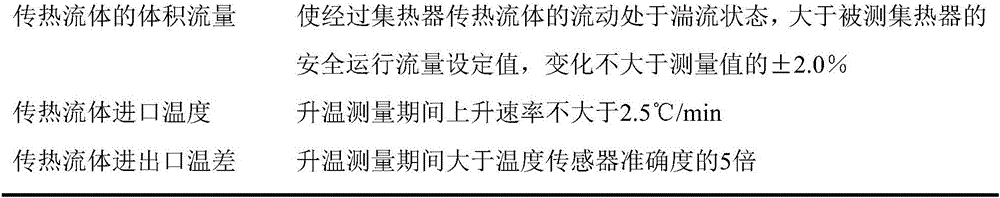

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1 As shown, the dynamic measurement device for the thermal performance of the parabolic trough solar collector of the present invention adopts a closed circulation system and consists of the following four subsystems: measuring instrument subsystem, heat transfer fluid circulation subsystem, nitrogen sealing subsystem main and cooling circulation subsystem. The measuring equipment of the measuring instrument subsystem is installed on or near the heat transfer fluid circulation subsystem, the nitrogen gas sealing subsystem is connected to the top of the heat exchanger 9 in the heat transfer fluid circulation subsystem, and the cooling circulation subsystem is connected to the heat transfer fluid circulation subsystem The inlet and outlet of the cooling medium side of the heat exchanger 9 .

[0034] The heat transfer fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com