A real-time measurement method for the residence time of flue gas in a waste incinerator at 850°C

A waste incinerator and residence time technology, which is applied in the monitoring field of power station boilers, can solve problems such as difficult natural degradation, human health and ecological environment safety hazards, and achieve good linearity, high sensitivity, stability and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0058] A method for real-time measurement of residence time of flue gas in a waste incinerator at 850°C, comprising the following operations:

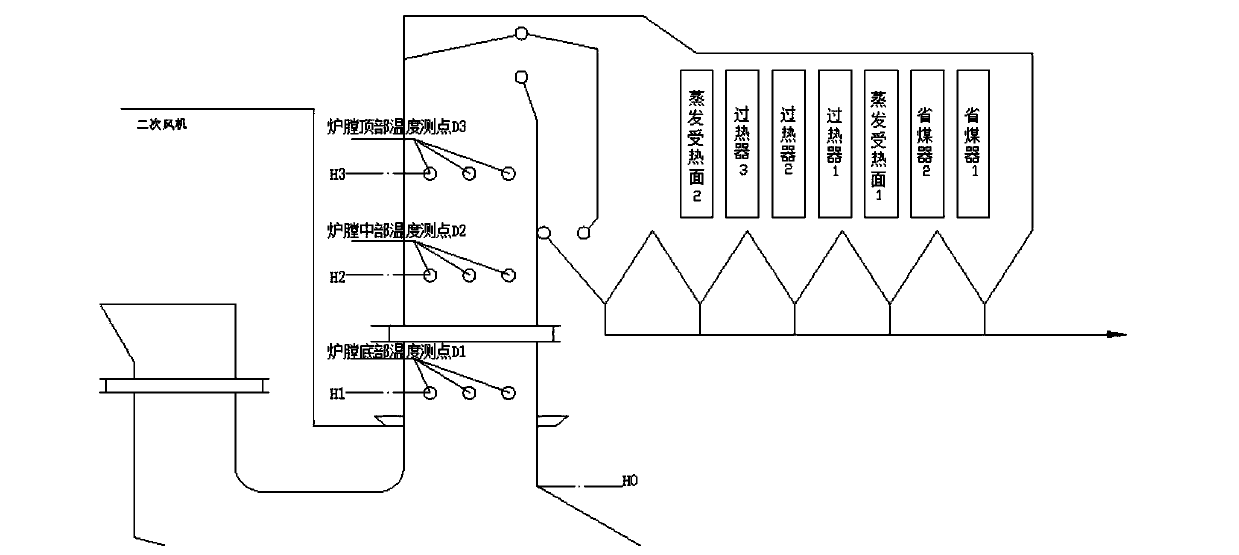

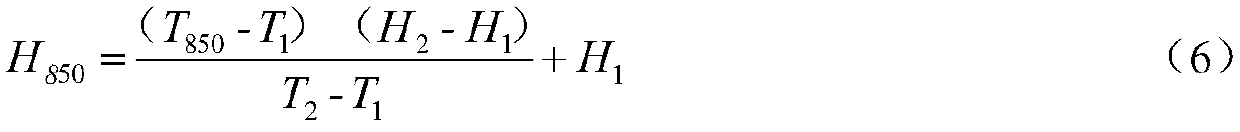

[0059] 1) Construct the real-time temperature field distribution along the furnace height in the incinerator:

[0060] In the waste incinerator, set multiple smoke temperature measuring points along the height direction of the vertical flue of the furnace, and the smoke temperature measuring points extend into the furnace to a depth of 200mm to 400mm; the real-time temperature field distribution in the incinerator is linearly attenuated along the height of the furnace, that is, The temperature at the lower part of the furnace is always greater than the temperature at the outlet of the furnace, and can be fitted with a linear function;

[0061] Specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com