Large diameter and high sensitivity high voltage DC cable leakage current detection sensor

A detection sensor, high-voltage direct current technology, applied in the direction of voltage/current isolation, current only measurement, current/voltage measurement, etc., can solve the problems of poor measurement effect, poor precision, low detection sensitivity, etc., and achieve high precision and good stability , Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

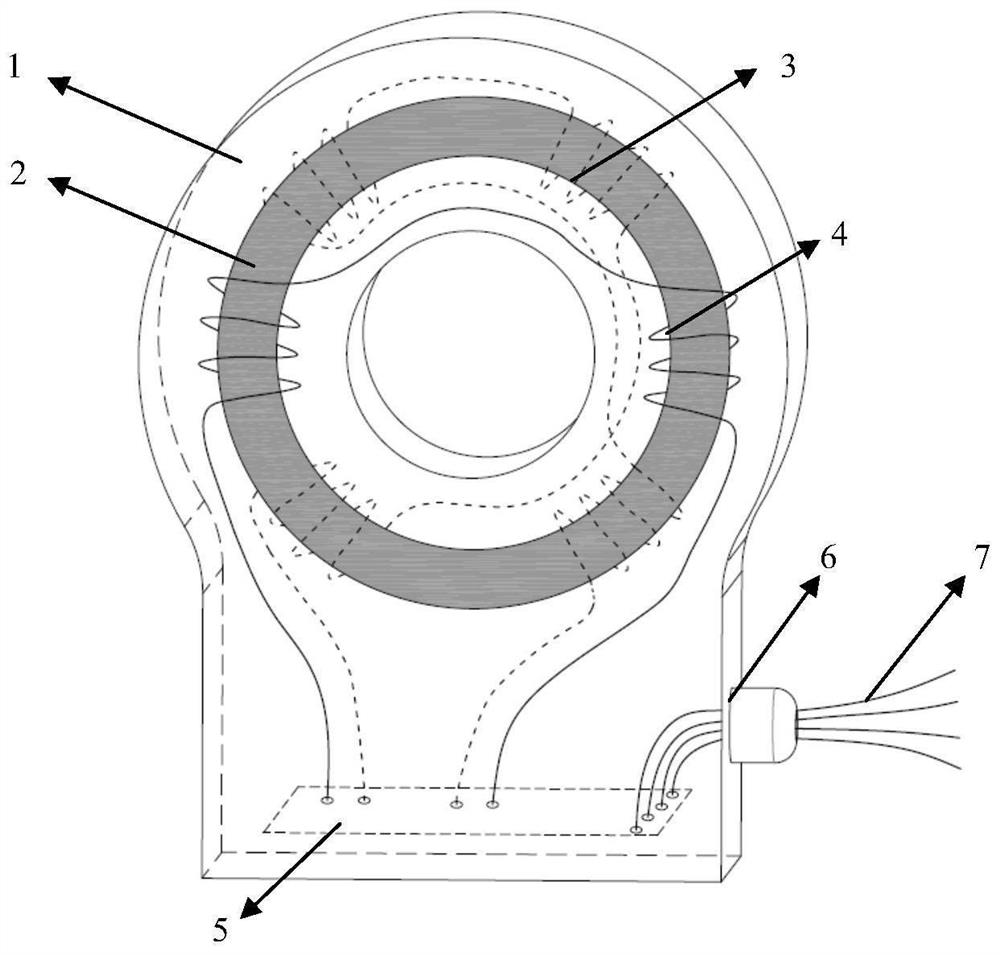

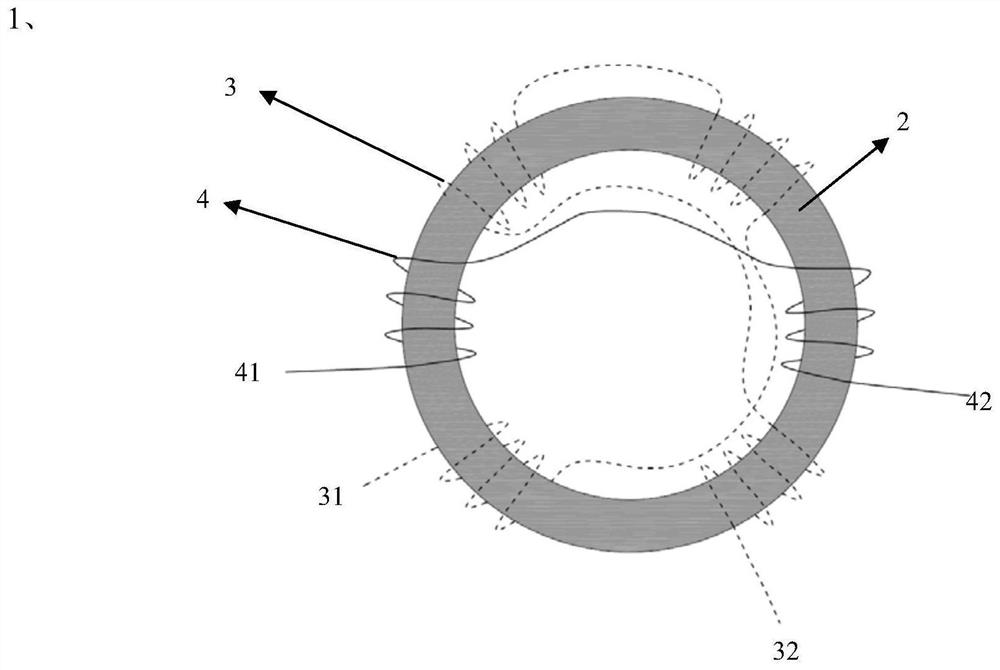

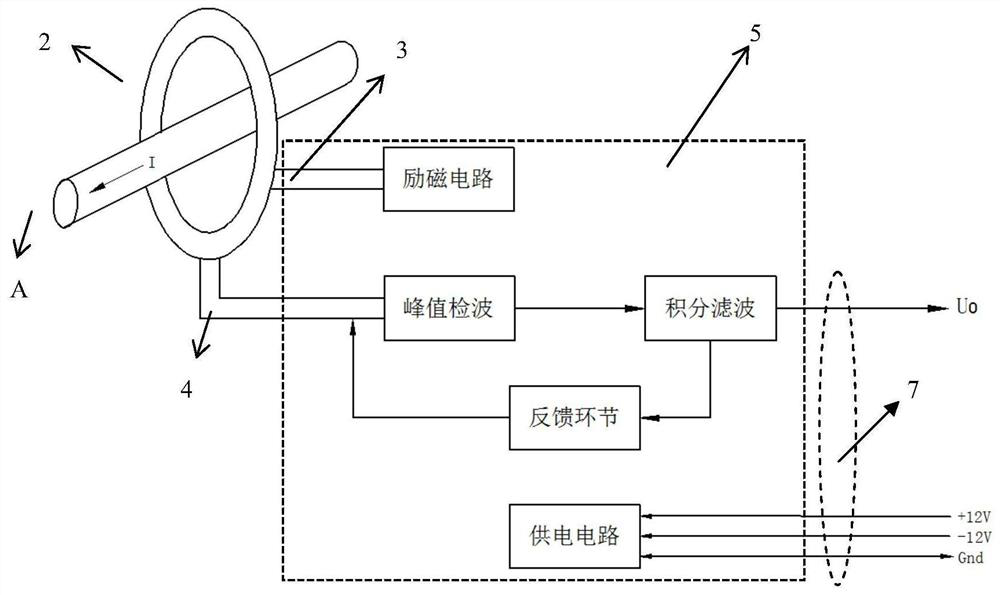

[0023] see Figure 1 to Figure 3, the large-caliber high-sensitivity high-voltage DC cable leakage current detection sensor includes a sensor housing 1, an annular iron core 2, a measuring coil 3, 4, a current signal acquisition and processing circuit board 5, a fastening bolt 6 and a sensor output signal line 7 After the annular iron core 2, the measuring coils 3 and 4 and the current signal acquisition and processing circuit board 5 are loaded into the sensor housing, the epoxy resin sealant is poured for overall sealing, and the sensor output signal line 7 is connected to the current signal acquisition and processing circuit board 5 for further processing. Signal transmission, and protrude out of the sensor housing 1 at the preset position through the fastening bolt 6 so as to be connected to the external device for detecting the current leakage value. The central hole diameter of the annular iron core 2 is not less than 40mm so that the cable to be tested can pass through. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com