Online monitoring device, detection circuit and testing method for junction temperature of electronic power switch

A technology of power electronic switch and monitoring device, which is applied in the field of power electronics, can solve the problems that have not been properly solved, the voltage dynamic range changes greatly, and it is difficult to accurately measure the millivolt level of the conduction voltage drop, so as to achieve the overall design ingenious, structural Compact and convenient for large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

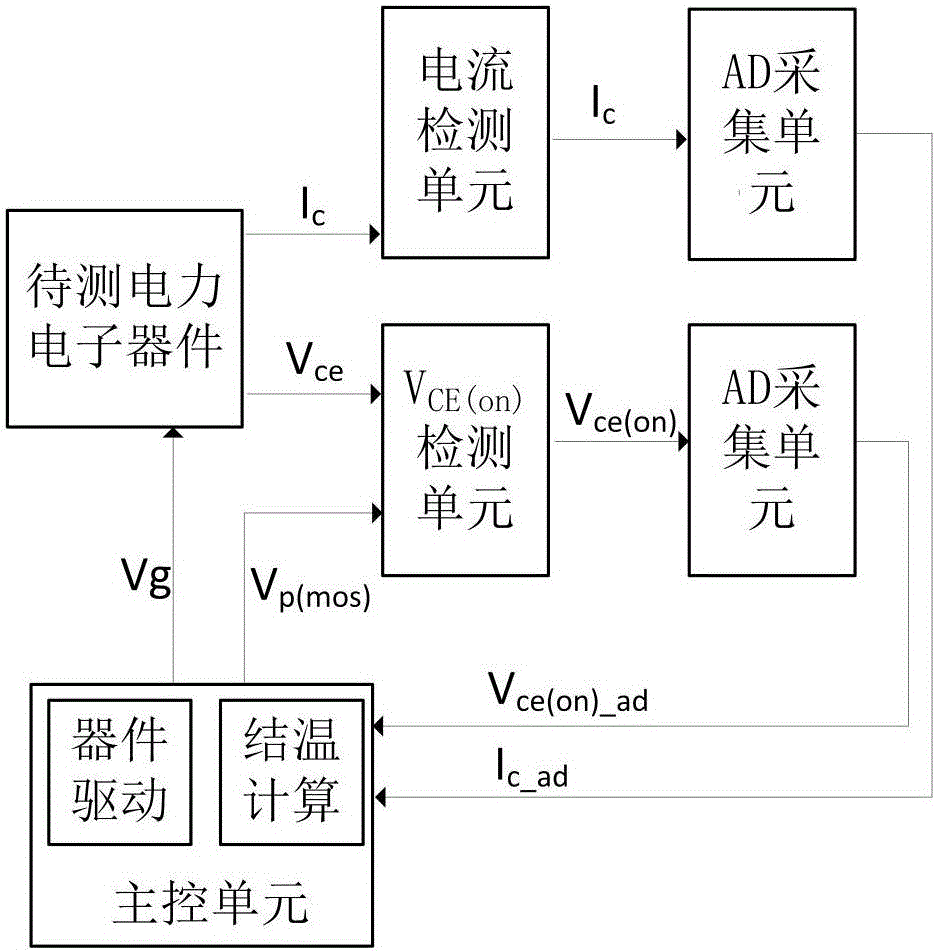

[0026] Embodiment 1: see figure 1 , an online monitoring device for the junction temperature of a power electronic switching device, the online monitoring device includes a main control unit, a power electronic device to be tested, a current detection unit, a V ce(on) A detection unit and an AD acquisition unit, wherein the main control unit includes a device drive unit and a junction temperature calculation unit. In this technical solution, the power electronic switching device to be tested includes common power electronic switching devices, including MOSFETs, IGBTs, etc.; the current detection unit is used for Acquisition of the current I flowing through the device in the on state of the device c , V ce(on) The detection unit is used to collect the conduction voltage drop V of a certain rated time period in the IGBT conduction state ce , through V ce(on) The analog circuit in the detection unit obtains the equivalent conduction voltage drop signal V ce(on , the AD acqui...

Embodiment 2

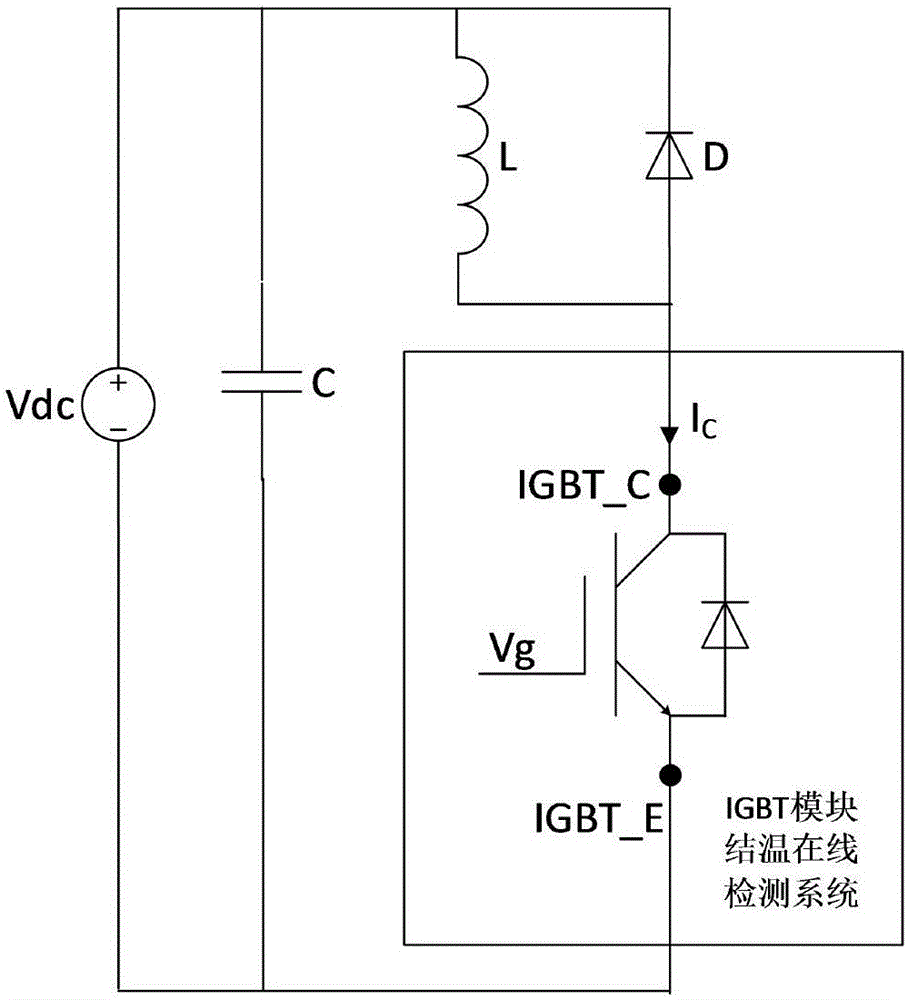

[0029] Example 2: see figure 2 , an IGBT detection circuit provided with an online junction temperature monitoring device of a power electronic switching device, wherein the detection circuit includes a bus DC voltage source Vdc, a bus capacitor C, a load inductance L, a power diode D, and an IGBT module junction temperature online detection system; wherein , the positive pole of the bus DC voltage source Vdc is connected to one end of the bus capacitor C, one end of the load inductance L to the cathode of the power diode D, and the other end of the load inductance is connected to the anode of the power diode D and the collector of the IGBT module to be tested in the IGBT module junction temperature online detection system IGBT_C is connected, and the emitter IGBT_E of the IGBT module to be tested in the IGBT module junction temperature online detection system is connected to the other end of the bus capacitor and the negative pole of the bus DC voltage source Vdc.

Embodiment 3

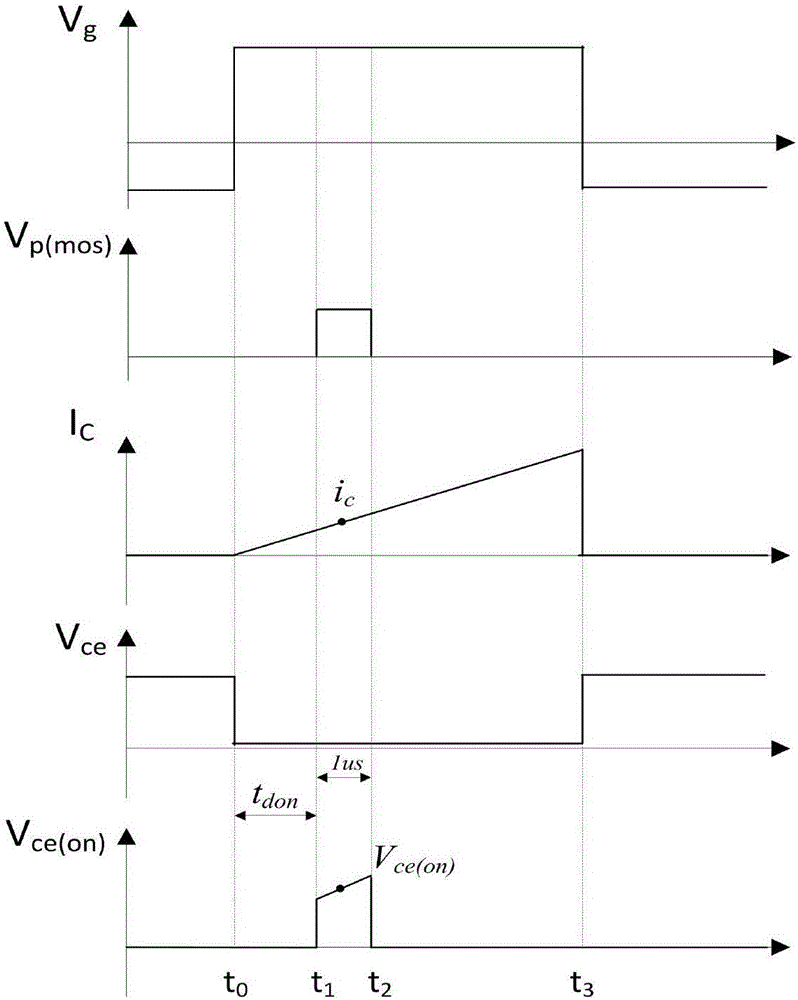

[0030] Embodiment 3: see image 3 , the test steps of the IGBT module junction temperature detection device using the IGBT module detection circuit are as follows: image 3 The timing diagram of IGBT drive and mos drive shown in the figure cooperates to complete the measurement of high-precision conduction voltage drop, at t 0 -t 3 During the time period, the switching control signal V of the gate of the IGBT module g is high level, the IGBT module to be tested is in the conduction state, and the switch control signal V of the gate of the IGBT module is in the rest of the time g is low level, the IGBT module to be tested is in the off state; at t 1 -t 2 During the time period, V ce(on) Q1 in the sense cell turns on, making V ce(on) The detection unit is connected to the IGBT module junction temperature online detection system, and the rest of the time V ce(on) Q1 in the detection cell turns off, so that V ce(on) The detection unit is disconnected from the IGBT module jun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com