Photolithography solution prediction method based on layout geometric feature matching

A solution and geometric feature technology, applied in the field of lithography solution prediction based on layout geometric feature matching, can solve problems such as inability to intuitively feedback layout design, inability to analyze unknown or undetected, and inability to provide unknown layout graphics, etc. Achieve the effect of shortening the development cycle, ensuring successful implementation, and reducing selection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

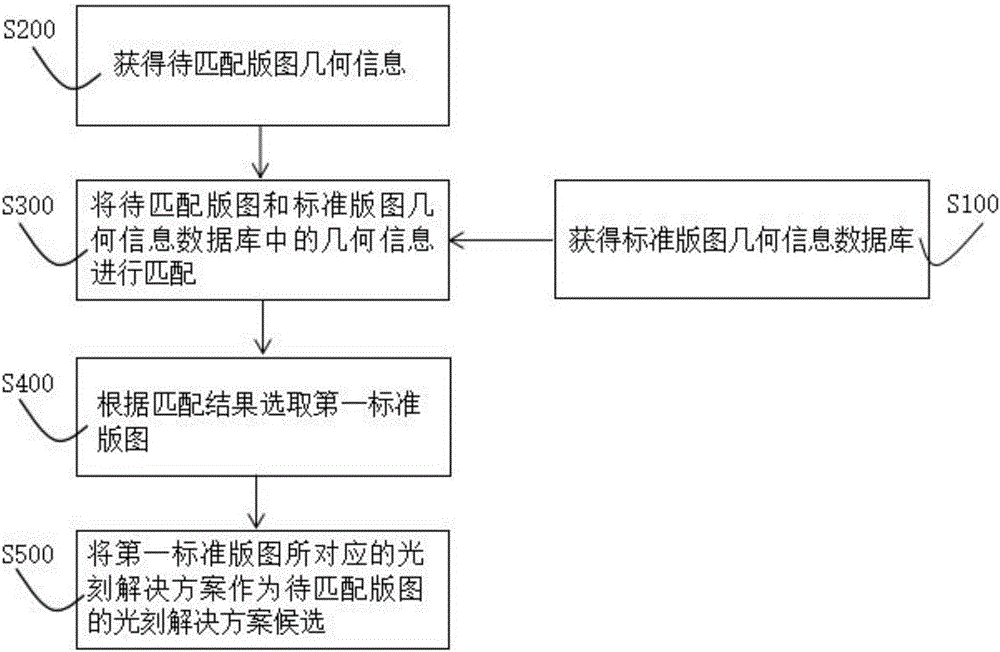

[0035] Embodiment 1 provides a lithography solution prediction method based on layout geometric feature matching, such as figure 1 As shown, the method includes:

[0036] S100: Obtain a standard layout geometric information database;

[0037] S200: Obtain geometric information of the layout to be matched;

[0038] S300: Match the layout geometric information to be matched with the geometric information in the standard layout geometric information database;

[0039] S400: Select a first standard layout according to the matching result;

[0040] S500: Using the lithography solution corresponding to the first standard layout as a candidate for the lithography solution of the layout to be matched, and predicting the lithography solution of the layout to be matched.

[0041] Embodiment 1 By establishing a standard layout geometric information database, the geometric information of the layout to be matched is obtained, and the statistical results of the geometric information of t...

Embodiment 2

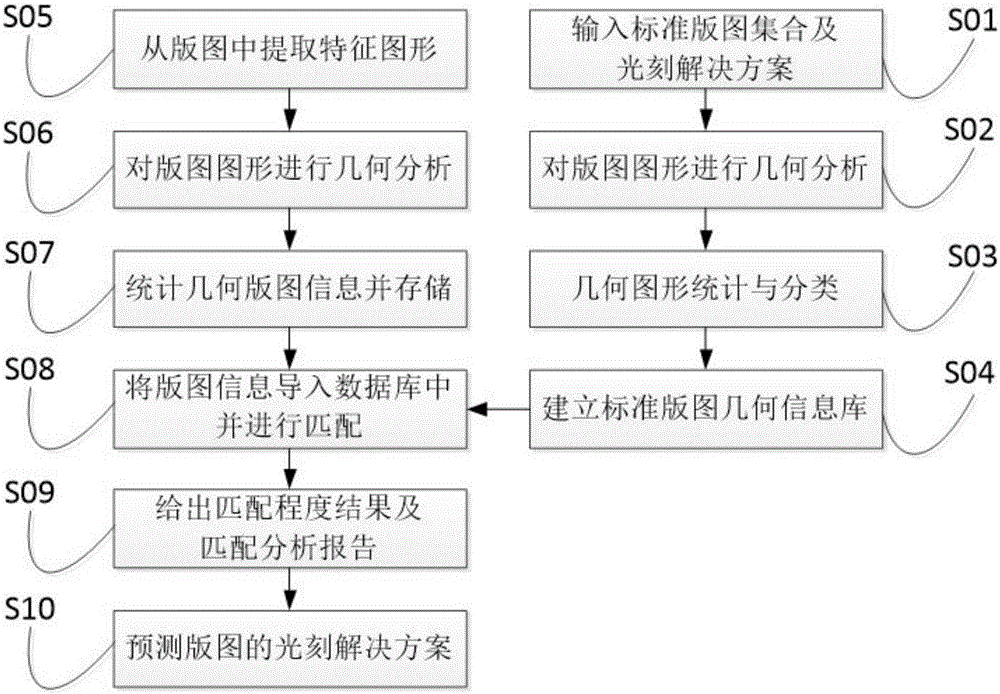

[0045] Embodiment 2 provides a lithography solution prediction method based on layout geometric feature matching, the method comprising:

[0046] Obtain a standard layout geometric information database;

[0047] Obtain geometric information of the layout to be matched;

[0048] matching the layout geometric information to be matched with the geometric information in the standard layout geometric information database;

[0049] selecting a first standard layout according to the matching result;

[0050] The lithography solution corresponding to the first standard layout is used as a candidate lithography solution of the layout to be matched, and the lithography solution of the layout to be matched is predicted.

[0051] Wherein, said obtaining standard layout geometric information database includes:

[0052] Obtain the standard layout collection and the lithography solution corresponding to each standard layout in the collection;

[0053] Obtaining geometric information of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com