Refueling water tank inside containment of nuclear power plant

A nuclear power plant containment and water tank technology, applied in nuclear power generation, nuclear engineering, cooling devices, etc., can solve problems that affect equipment reliability and layout convenience, raise the height of the main circuit equipment layout, and increase the overall height of the reactor building, etc. Achieve the effect of ensuring water quality stability and reliability, improving reliability and convenience of layout, and improving mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

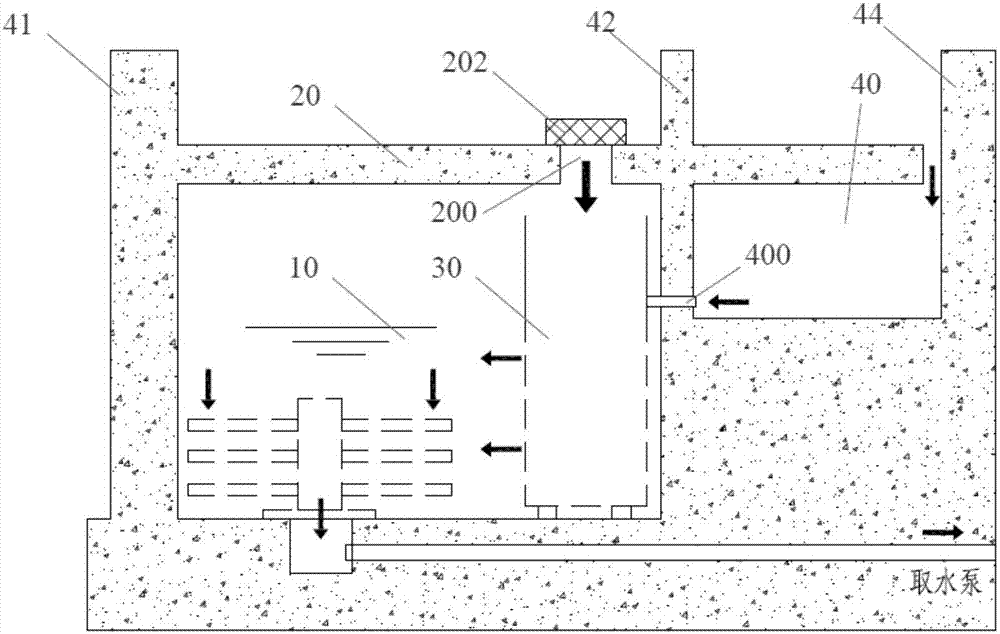

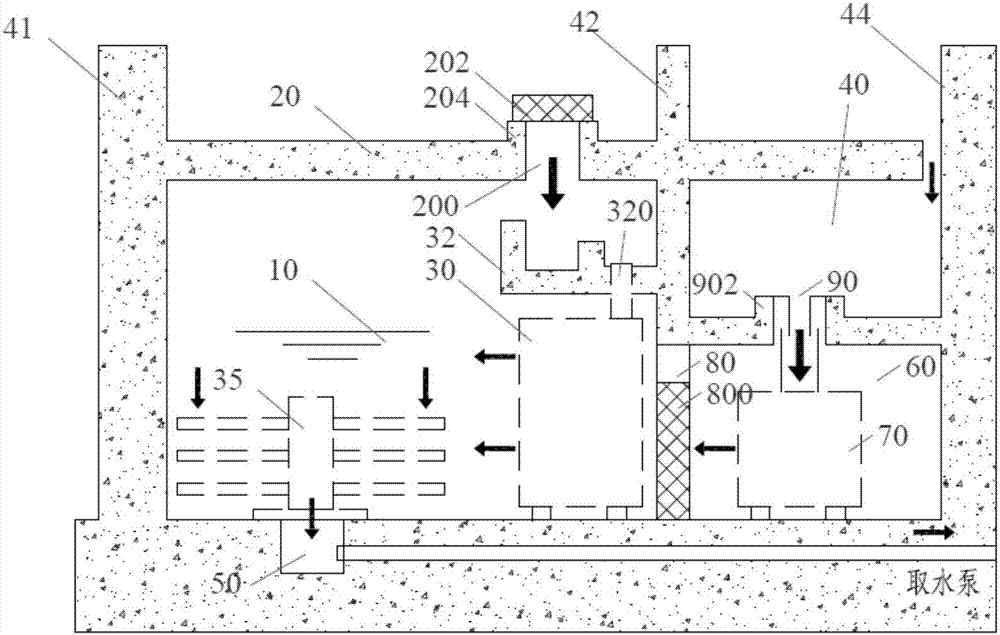

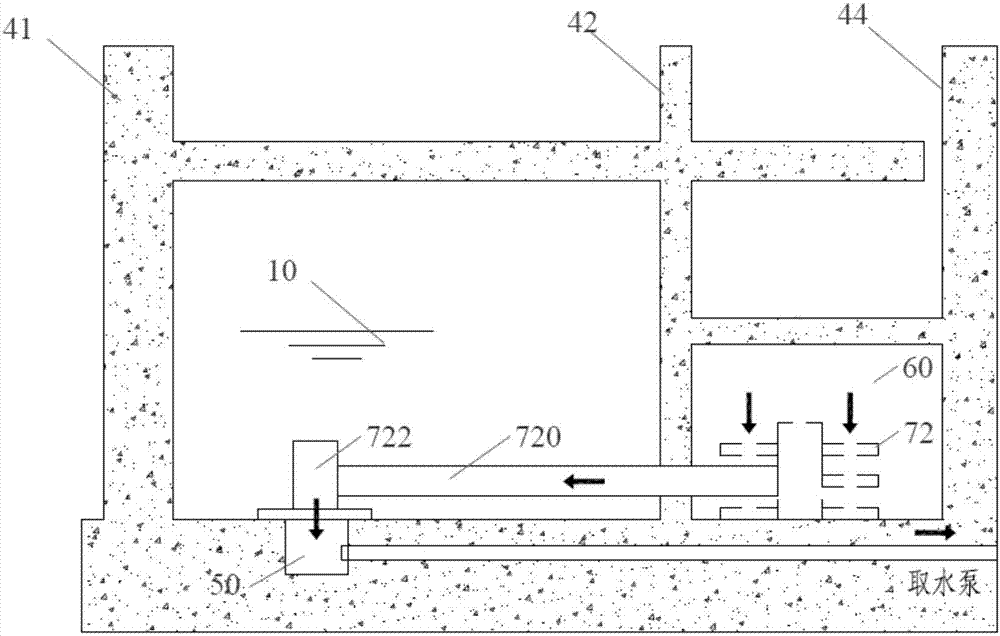

[0034] see figure 2 As shown, the refueling water tank inside the nuclear power plant containment of the present invention includes: an inner ring pool 10 located between the nuclear power plant reactor pit 41 and the secondary shielding wall 42 and a load-bearing floor 20 above the inner ring pool 10, the load-bearing floor 20 is provided with The inner ring water return hole 200, the inner ring water pool 10 is provided with an inner ring retention basket 30 corresponding to the inner ring water return hole 200, and an inner ring backflow buffer pool is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com