A composite mov component with discharge structure

A composite and component technology, applied in the direction of varistors, varistor cores, resistance terminals/electrodes, etc., can solve problems such as hindering the application field and affecting the service life of MOV, and achieve easy processing and great economic use value , no leakage current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

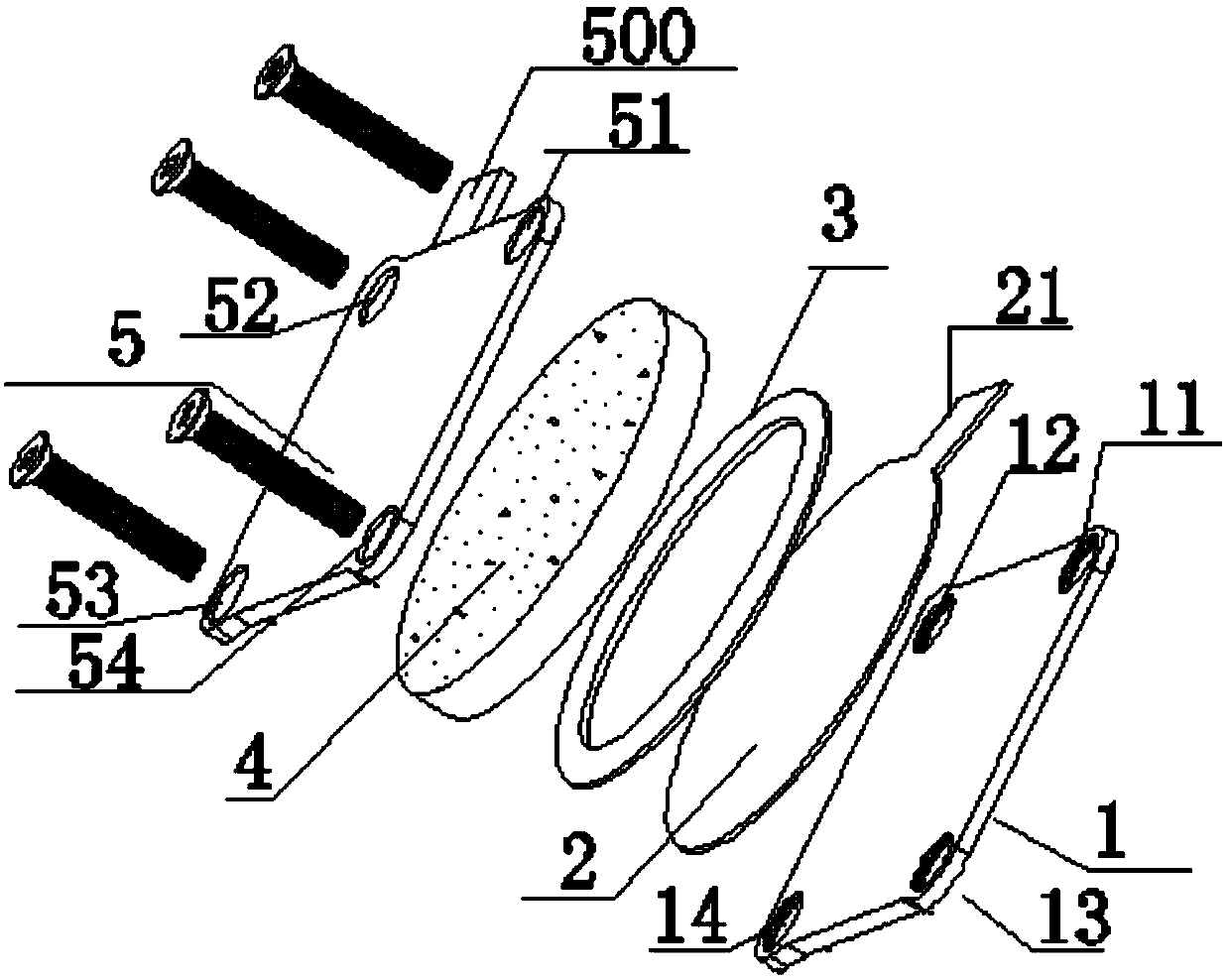

[0031] Such as figure 1 As shown, the present invention provides a composite MOV assembly with a discharge structure, that is, an FDMOV assembly, including an insulating fixed plate 1, a discharge electrode sheet 2, an insulating ring sheet 3, an MOV chip 4, a tripping electrode 5 and a fastener, The MOV chip 4 is a circular MOV chip 4 .

[0032] The insulating fixing plate 1 is a rectangular insulating fixing plate, and four screw holes 11 , 12 , 13 , 14 are provided at the four corners of the rectangular insulating fixing plate.

[0033] Described discharge electrode sheet 2 is circular discharge electrode sheet, and the straight edge of described circular discharge electrode sheet is identical with described circular MOV chip, and described discharge electrode sheet 2 is also provided with lead-out electrode 21.

[0034] The insulating ring sheet 3 is an annular insulating ring sheet, and the profile of the annular insulating ring sheet is 1-5mm larger than the diameter of...

Embodiment 2

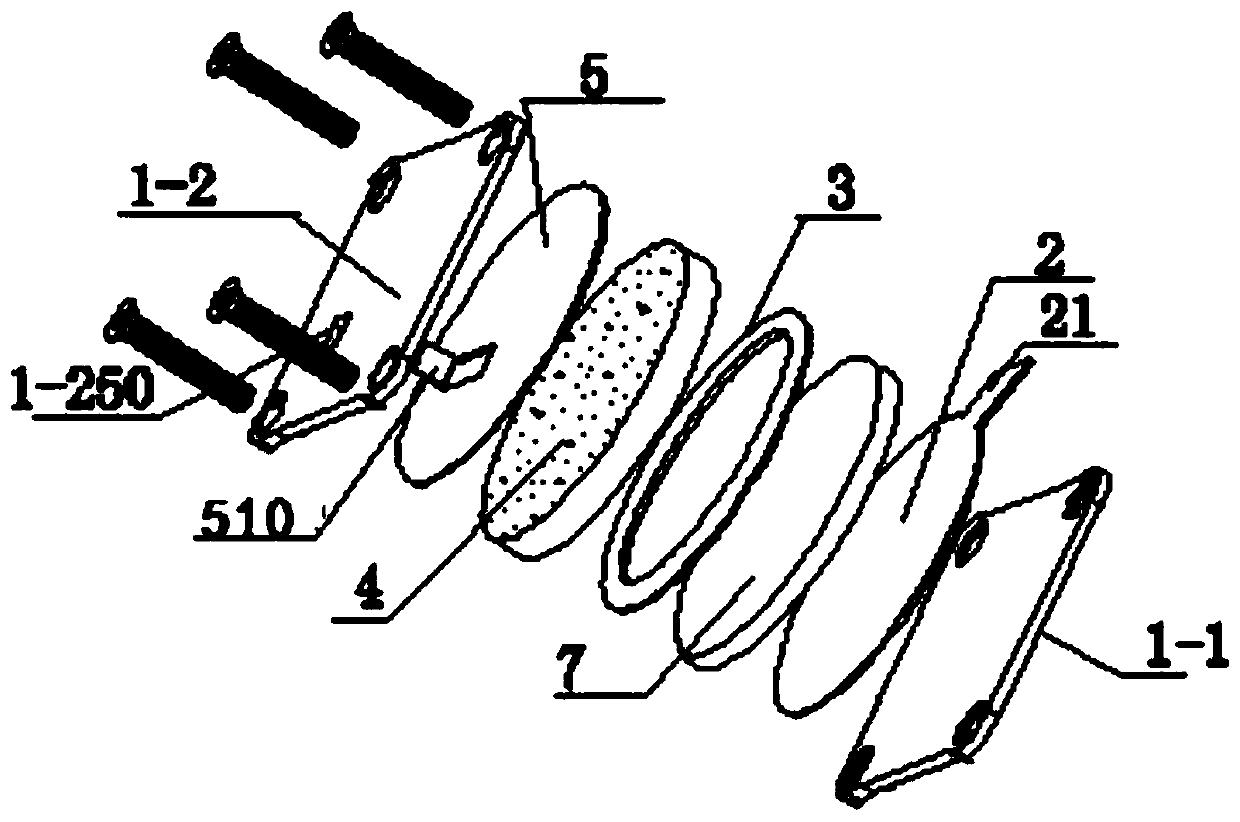

[0042] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that it includes a discharge electrode 7, and the discharge electrode 7 is arranged between the discharge electrode sheet 2 and the insulating ring sheet 3, and the insulating fixing plate includes a second An insulating fixing plate 1-1 and a second insulating fixing plate 1-2, the second insulating fixing plate 1-2 is arranged above the tripping electrode 5, and the second insulating fixing plate 1-2 is provided with a groove Holes 1-250 and fasteners;

[0043]A discharge electrode 7 is added between the discharge electrode sheet 2 and the insulating ring sheet 3, the discharge electrode sheet 2 is used as a lead-out electrode, the tripping electrode 5 is a circular tripping electrode, and the circular tripping electrode 5 is a circular tripping electrode. The diameter of the electrode is the same as the diameter of the MOV chip, and the circular trip electrode is provided with a l...

Embodiment 3

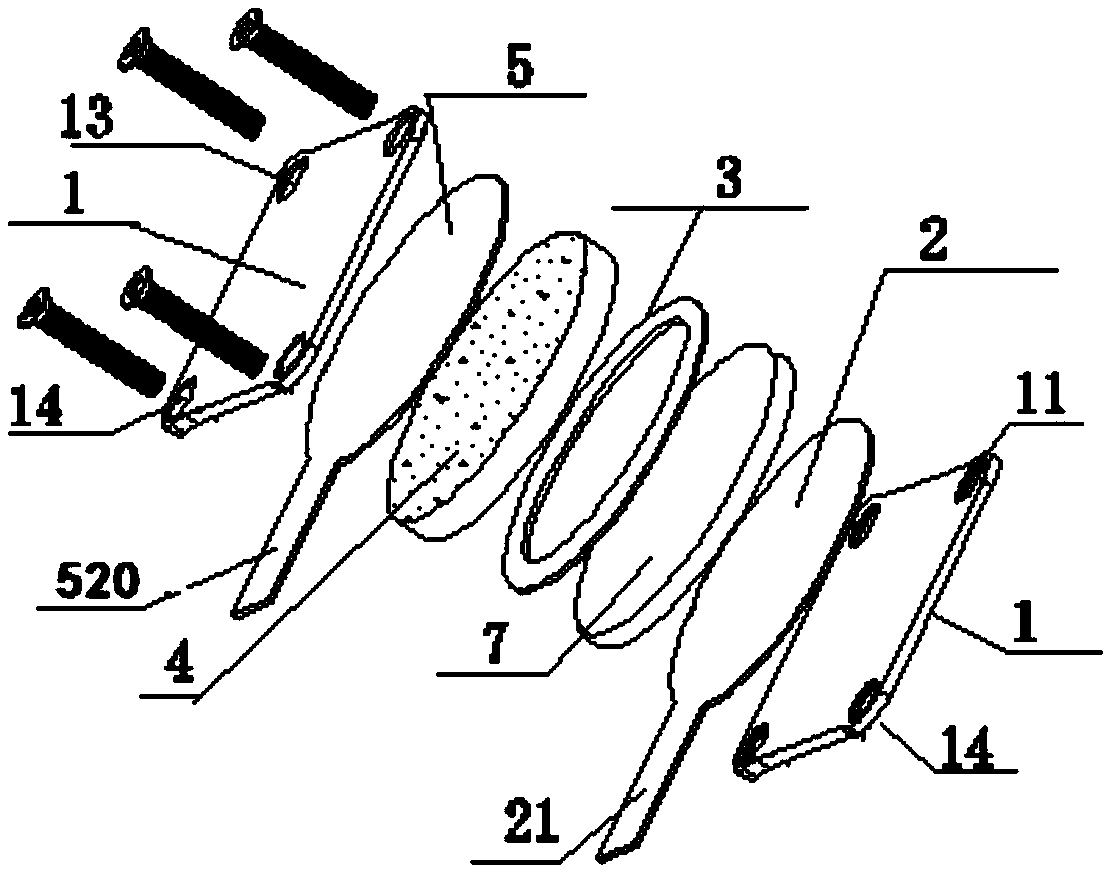

[0046] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the lead-out pin 520 of the tripping electrode 5 is set to lead out in a radial direction and extended so that the FDMOV with air discharge can be used in a PCB circuit board components.

[0047] Such as Figure 4 Shown are the equivalent circuit diagrams of Embodiment 1, Embodiment 2, and Embodiment 3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com