Split-type high-pressure cavity structure and measurement method for comprehensive dielectric property measurement

A dielectric performance, split-type technology, which is applied in the field of split-type high-pressure and high-strength cavity structure and measurement, can solve problems affecting peripheral devices, etc., and achieve the effect of convenient installation and removal, convenient disassembly, and accurate dielectric performance measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

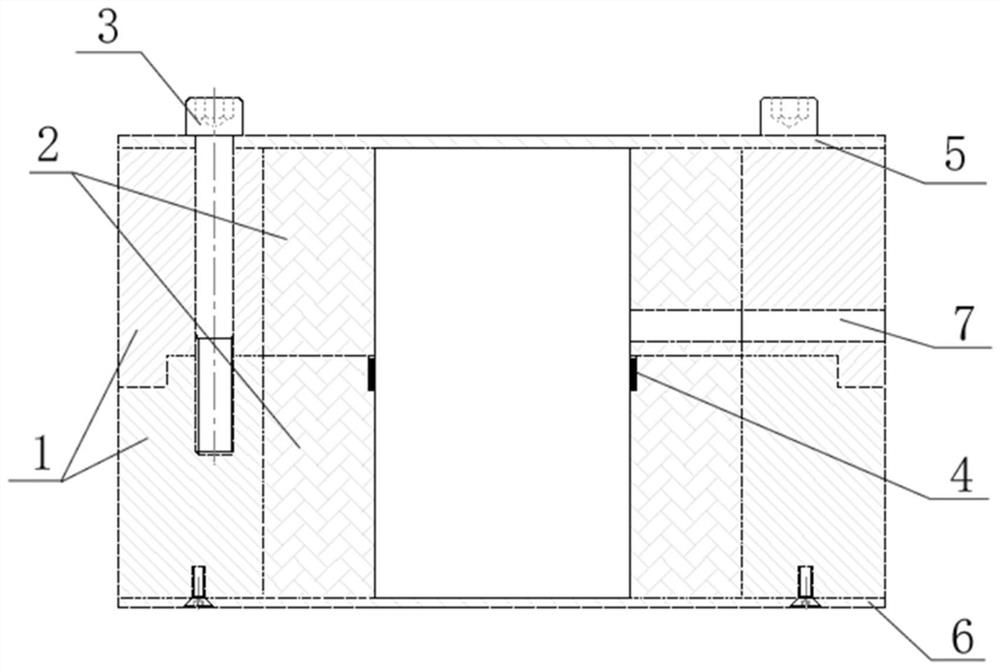

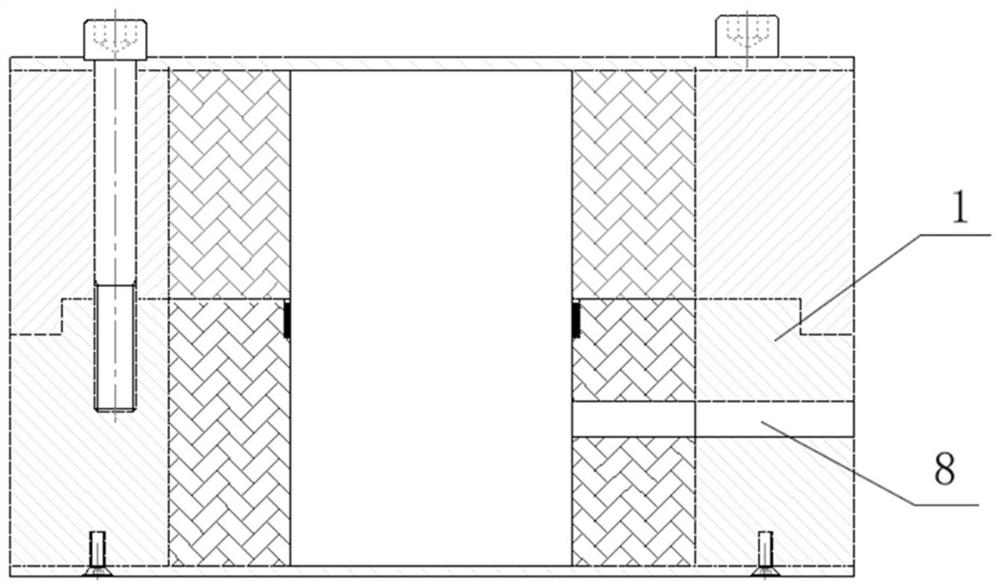

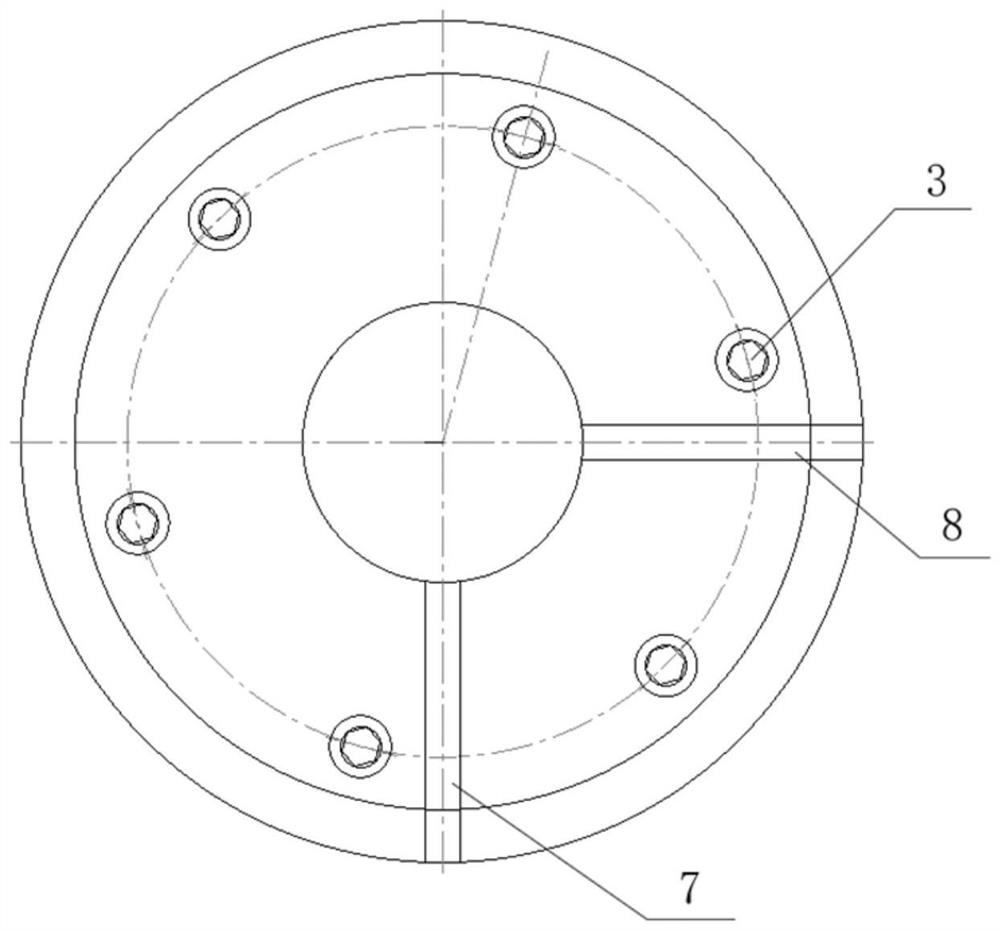

[0049] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this embodiment provides a split-type high-pressure cavity structure for comprehensive dielectric performance measurement, which is used to measure the comprehensive dielectric performance of insulating dielectrics, including dielectric constant, dielectric loss tangent, conductivity, space charge, glass transition pressure, etc.

[0050] The following content firstly describes the structure of the split type high-pressure chamber in detail, and then discusses how to use the invented split-type high-pressure chamber structure to measure the comprehensive dielectric properties.

[0051] 1. Split type high pressure chamber structure

[0052] The split-type high-pressure cavity structure includes an anti-expansion protection steel sleeve 1, an epoxy glass fiber sleeve 2, a first connection hole 7 and a second connection hole 8, and the anti-expansion protection steel sleeve 1 is set on the epoxy glass On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com