LRC component structure

A component structure and component technology, which is used in electrical components, electrical solid devices, semiconductor devices, etc., to reduce mechanical stress, simplify component structure, and save installation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

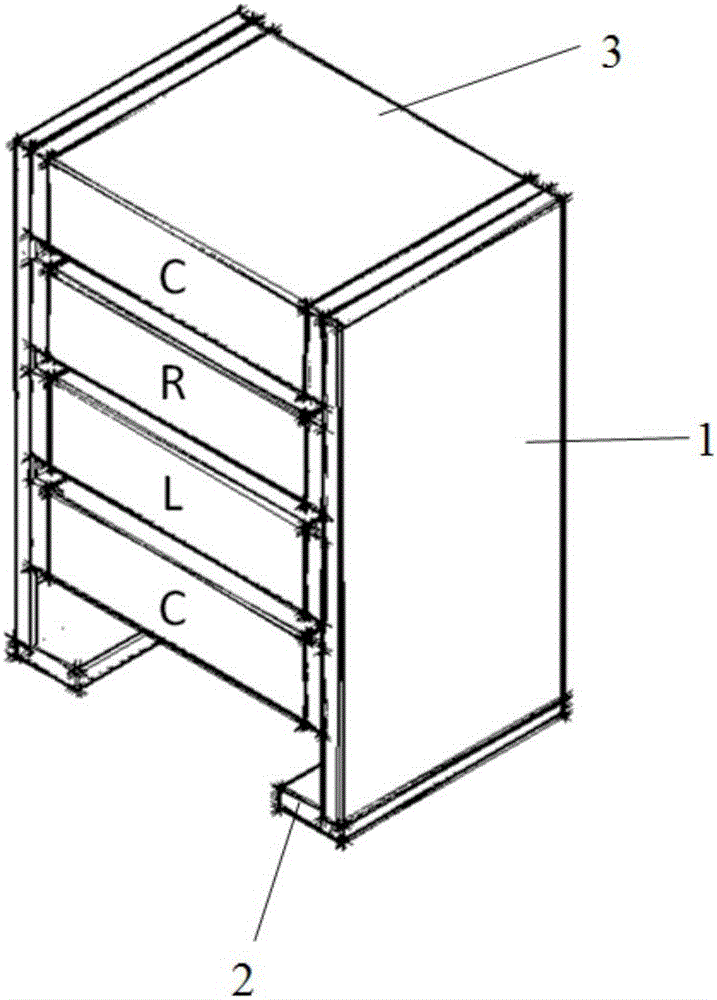

[0021] Realize the parallel LRC resonant tank M1, the structure is as follows figure 1 As shown, it includes: two pole plate supports 1, at the lower ends of the two pole plate supports 1 there are pins 2 inclined inwardly or outwardly, and the pins are fixedly connected with the circuit board. The multi-piece RC-sensing elements 3 are welded on the inner side of the two pole plate supports 1, the multi-piece RC-sensing elements 3 are connected in series or in parallel, and the multi-piece RC-sensing elements 3 are stacked vertically or arranged horizontally.

[0022] The LRC component structure is done in the following steps:

[0023] 1. Processing and treatment of pole plate support: process the required metal pole plate by machining, and then perform electroplating treatment to form an electroplating layer on the surface of the pole plate support.

[0024] 2. Chip bonding: According to the principle of the circuit diagram, the size and parameters of the resistance-capacita...

Embodiment 2

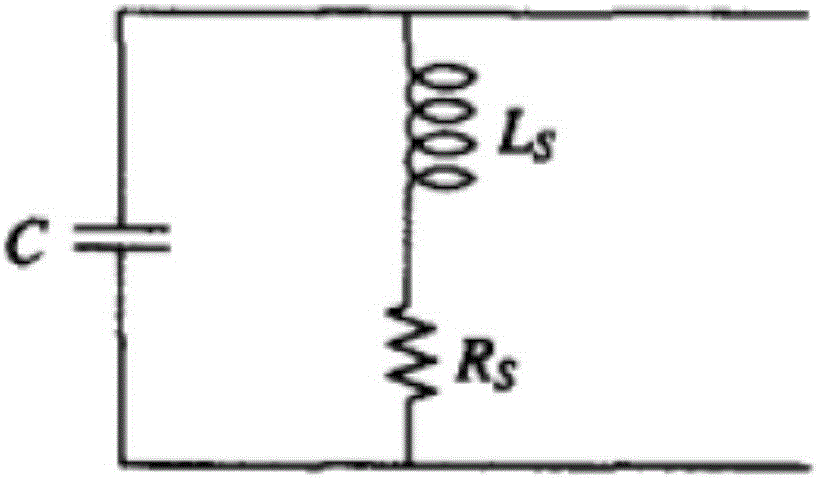

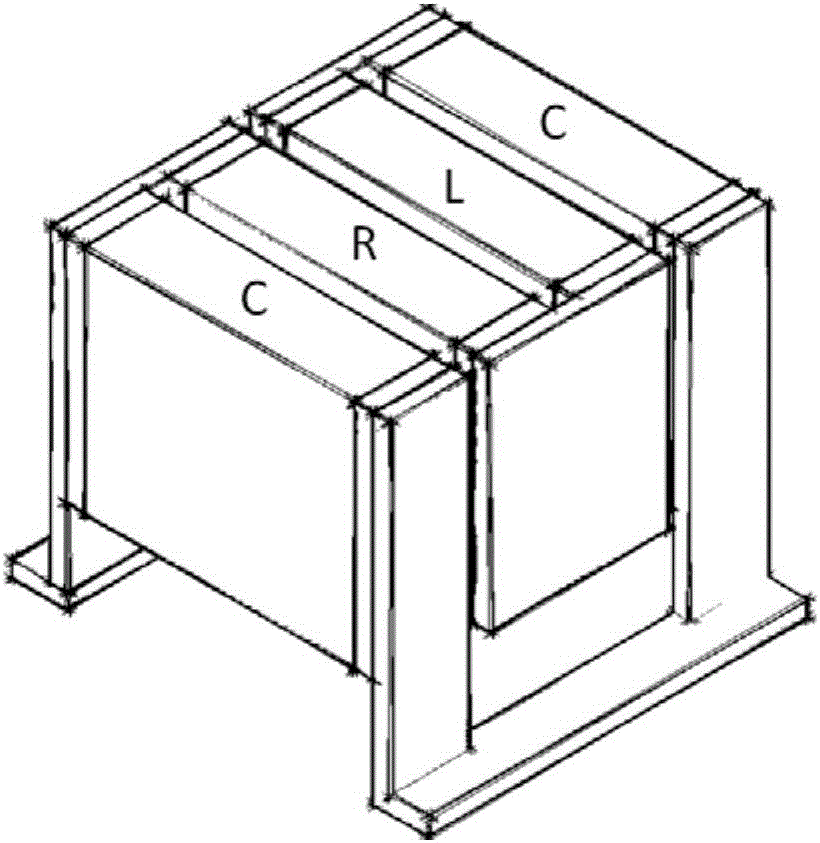

[0029] Series-parallel LRC resonance circuit M2, the circuit schematic diagram is as follows figure 2 Shown, the modular component structure designed by the method of the present invention is as image 3 As shown, the series connection of L and R and the parallel connection with C can be realized, and the corresponding pins can be soldered according to the needs during use.

Embodiment 3

[0031] A π-type low-pass filter (LPF) M3, the circuit schematic diagram is as follows Figure 4 As shown, for modular replacement, the LRC component structure is as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com