Conductive nanowire layer and graphical method and application thereof

A conductive nano-patterning technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of metal layer and substrate falling off, cumbersome patterning methods, etc., and achieve the effect of uniform light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0042] The patterning method of the conductive nanowire layer in this embodiment is as follows:

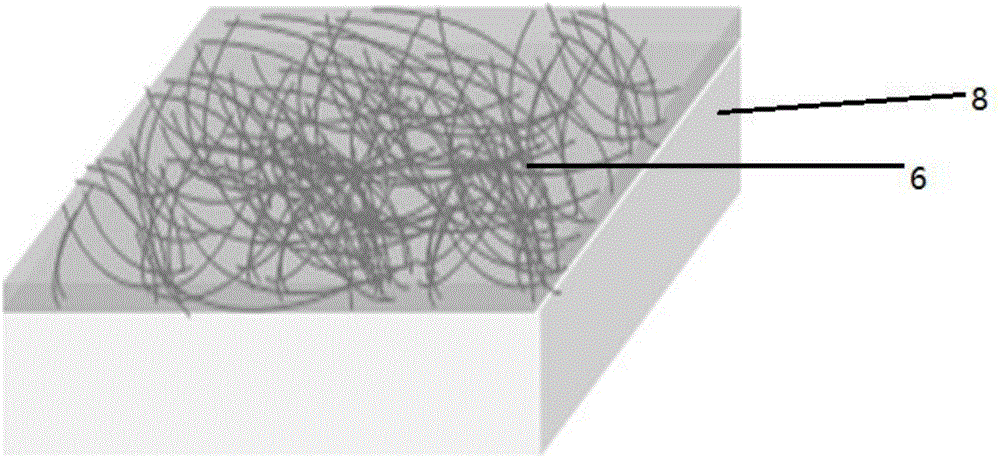

[0043] The conductive nanowire material and the photoresist are uniformly mixed to form a mixed solution, the mixed solution is coated on the substrate and then exposed for an exposure time of 1-120s, after curing, forming, and developing to obtain a conductive nanowire layer. Coating adopts spin coating or blade coating.

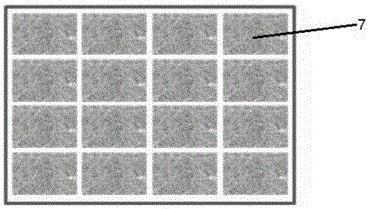

[0044] Different exposure masks can be used to obtain conductive nanowire layers with different patterns after exposure and development, such as image 3 In the regularly arranged conductive nanowire layer 7. Light passing through Figure 5 After the exposed area 21 of the middle mask is irradiated with the mixed solution in the corresponding area to cure it, the non-exposed area 22 can block the light, and the mixed solution in the corresponding area does not cure and is removed by washing.

[0045] Table 1 Process condition parameter table of the patterning method ...

Embodiment 5-8

[0052] The patterning method of the conductive nanowire layer in this embodiment is as follows:

[0053] The conductive nanowire material and the ultraviolet curing adhesive are patterned by uniformly mixing the conductive nanowire material and the ultraviolet curing adhesive to form a mixed solution, and the mixed solution is coated on the substrate and then cured by ultraviolet light After molding, a conductive nanowire layer is obtained. Coating adopts spin coating or blade coating.

[0054] Different exposure masks can be used to obtain conductive nanowire layers with different patterns after exposure and development, such as image 3 In the regularly arranged conductive nanowire layer 7. Light passing through Figure 5 After the exposed area 21 of the middle mask is irradiated with the mixed solution in the corresponding area to cure it, the non-exposed area 22 can block the light, and the mixed solution in the corresponding area does not cure and is removed by washing.

[005...

Embodiment 9-12

[0062] The patterning method of the conductive nanowire layer in this embodiment is as follows:

[0063] The conductive nanowire material and the thermal curing glue are uniformly mixed to form a mixed solution, and the mixed solution is coated on the substrate, and then heated and cured to form a mixed solution. Coating adopts spin coating or blade coating.

[0064] Different heat curing templates can be used such as Image 6 The heating mask shown is heated and cured to obtain conductive nanowire layers with different patterns, such as image 3 In the regularly arranged conductive nanowire layer 7. During the heating and curing process, the mixed solution coating in the area corresponding to the heating area 11 is heated and cured to form a conductive nanowire layer, and the mixed solution corresponding to the non-heating area 12 is not cured and is removed by washing.

[0065] Table 3 Process condition parameter table of the patterning method in Examples 9-12

[0066] Serial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com