Cylindrical lithium-ion battery pole piece winding and deburring method

A lithium-ion battery, cylindrical technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of short circuit of cells, reduce battery cycle performance and safety performance, etc., to prevent falling off, reduce short circuit of cells, The effect of improving cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

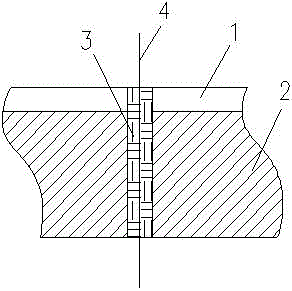

[0018] Such as figure 1 As shown, a cylindrical lithium-ion battery pole piece winding deburring method, the lithium-ion battery pole piece includes a current collector 1 and a positive and negative active material layer 2, and the positive and negative active material layer 2 passes through the lithium ion battery batching and coating process Coated on the current collector 1, and then through rolling, continuous baking, and slitting processes, the lithium-ion battery pole piece is made, and a tape sticking device is added before the cutting position of the winding machine, and the lithium-ion battery pole piece is wound At the same time, after the winding of a single core is completed, before the cutter cuts the lithium-ion battery pole piece, the tape sticking device sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com