Preparation method of graphene anticorrosive coating on stainless steel surface

A technology of anti-corrosion coating and graphene layer, which is applied in the direction of coating, metal material coating process, final product manufacturing, etc., can solve the problems of non-corrosion resistance, high-temperature fuel cells cannot have a long life, etc., and achieve the change of wettability , Remarkable anti-corrosion performance, simple and efficient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

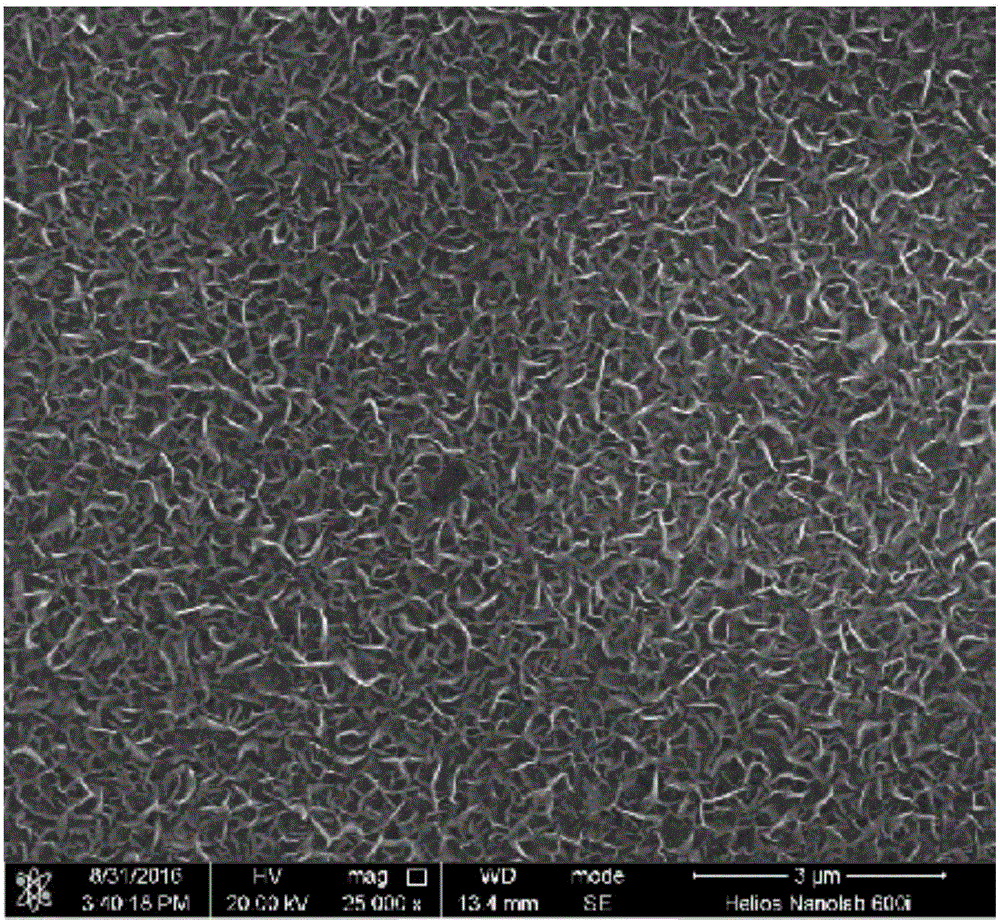

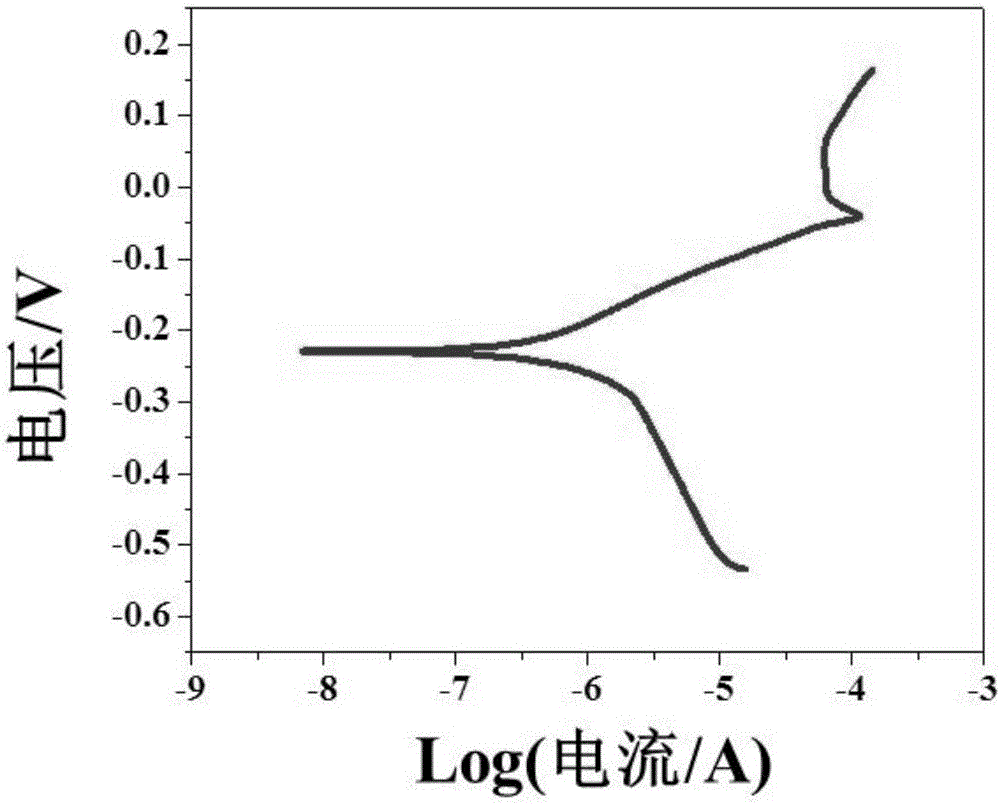

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment 1: The method for preparing a graphene anticorrosive coating on stainless steel surface described in this embodiment is carried out according to the following steps:

[0026] 1. Surface pretreatment of stainless steel:

[0027] Polish the stainless steel with metallographic sandpaper of 600 mesh, 1000 mesh and 1500 mesh in turn, and then ultrasonically clean the polished stainless steel with acetone, absolute ethanol and deionized water for 20 minutes to obtain pretreated stainless steel;

[0028] 2. Preparation of graphene oxide solution:

[0029] Dissolve graphene oxide in deionized water to obtain a graphene oxide solution with a concentration of 1 mg / mL to 10 mg / mL;

[0030] 3. Graphene oxide layer on the surface of stainless steel:

[0031] ① Take the pretreated stainless steel side as the dripping surface, and use 5μL / cm 2 ~20μL / cm 2 Use a spin coater to drop the graphene oxide aqueous solution with a concentration of 1mg / mL~10mg / mL on the pretreated stai...

specific Embodiment approach 2

[0043] Specific embodiment two: this embodiment is different from specific embodiment one in that the stainless steel mentioned in step one is 304 stainless steel, 316 stainless steel, 316L stainless steel or 321 stainless steel. Others are the same as the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: this embodiment is different from one of specific embodiments one or two in that in step two, graphene oxide is dissolved in deionized water to obtain a graphene oxide solution with a concentration of 1 mg / mL. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com