A preparation process of hydrogen fuel cell membrane electrode

A technology of fuel cell membrane and preparation process, which is applied in the field of battery membrane electrodes, can solve the problems of limiting the electrochemical performance of fuel cells, the uncontrollable adhesion strength of catalysts, and the non-reusable transfer medium, which is conducive to large-scale production and saves Film laying time and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

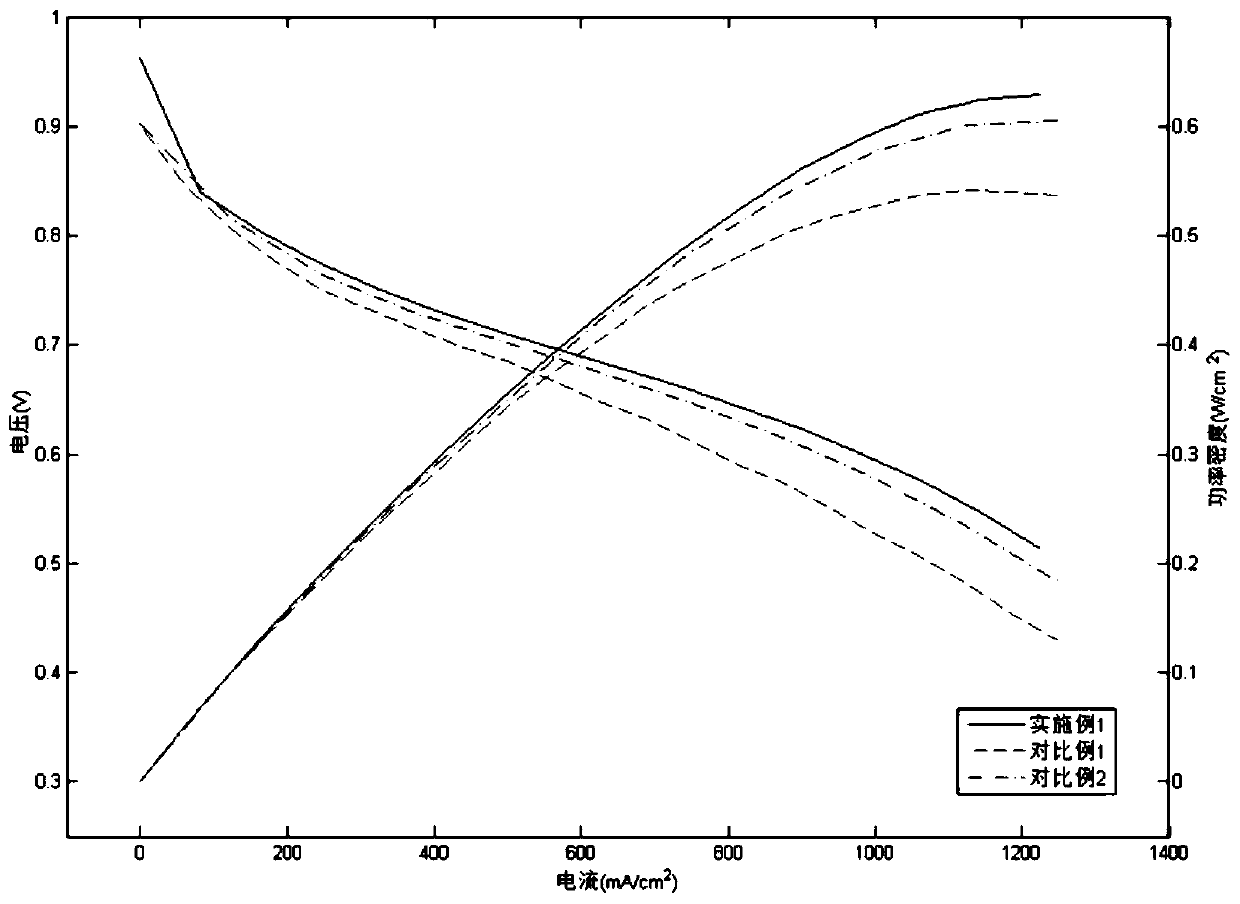

Embodiment 1

[0022] Put carbon powder and isopropanol into a beaker and ultrasonically mix it for 20 minutes to obtain a carbon powder slurry; then take an appropriate amount of 5% Nafion solution and dilute it with water to obtain a binder slurry; then use 60% Pt / C catalyst, isopropyl Alcohol, 5% Nafion solution to configure the electrocatalyst slurry.

[0023] Take a high-temperature cloth of appropriate size and weigh it first, then place it on the heating platform of the ultrasonic spraying instrument, turn on the vacuum pump to absorb the high-temperature cloth evenly. First spray the toner slurry, after weighing to ensure that the toner loading is 0.6mg / cm 2 ; then spray the catalyst slurry with an anode loading of 0.24 mg / cm 2 , the cathode loading is 0.48mg / cm 2 ;Finally spray Nafion slurry on the catalytic layer with a load of 0.1mg / cm 2 .

[0024] Place two pieces of high-temperature cloth sprayed with different loads of cathode and anode on both sides of the DuPont 211 film,...

Embodiment 2

[0027] Same as Example 1, except that the carbon powder loading becomes 1mg / cm 2 .

Embodiment 3

[0029] Same as Example 1, except that the Nafion load becomes 0.3mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com