A temperature control method for a power distribution cabinet

A technology for power distribution cabinets and power distribution rooms, which is applied in temperature control, non-electric variable control, substation/power distribution device shells, etc. It can solve the problems of affecting heat dissipation effect, waste of space cost, and short service life of electrical components, etc., to achieve Good heat dissipation effect, improve the safety of use, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

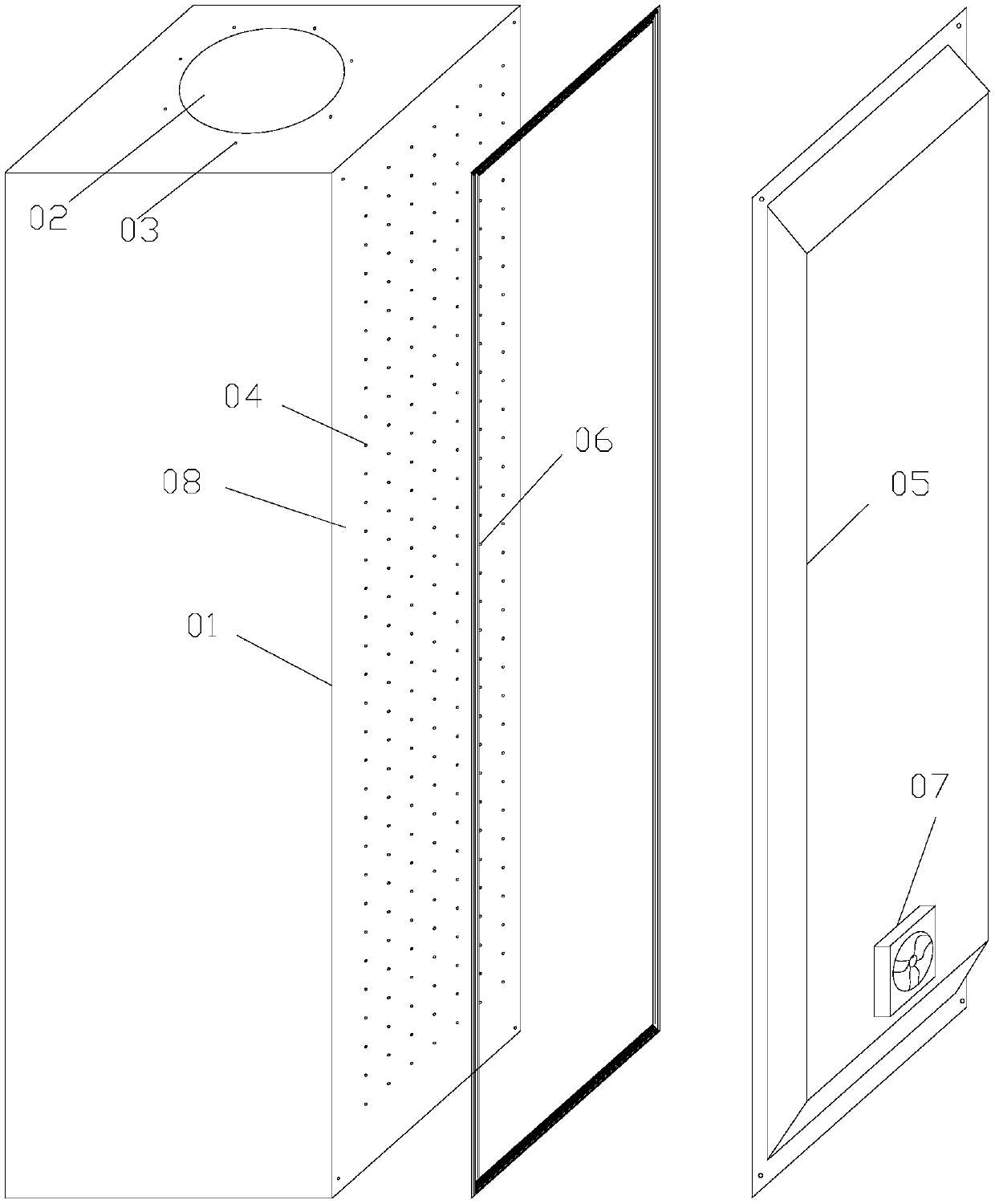

[0037] Such as figure 1 As shown, the power distribution cabinet described in this embodiment, the power distribution cabinet, includes a cabinet body 01, which is characterized in that the top of the cabinet body 01 is provided with a ventilation hole 02, and a circle of first installation holes 03 is provided on the periphery of the ventilation hole 02 ; The backboard 08 of the cabinet body 01 is covered with screw holes 04, and a back chamber 05 is connected to the back of the cabinet body 01, and a frame-type sealing strip 06 is provided between the backboard 08 and the back chamber 05; A fan 07 is provided at the bottom of the back cavity 05 .

[0038] The beneficial effect of the power distribution cabinet described in this embodiment is that the backboard 08 is covered with screw holes 04, and components such as bus ducts and clips for installing electrical components are directly installed on the backboard through screws. 07 When turning to the internal air supply, th...

Embodiment 2

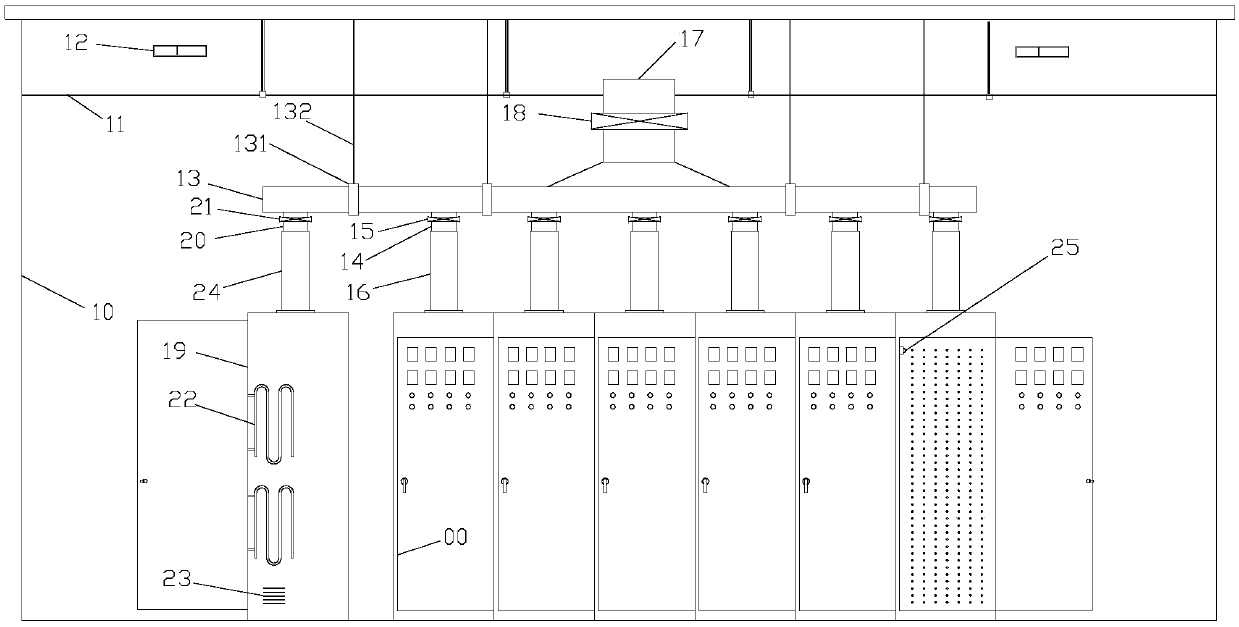

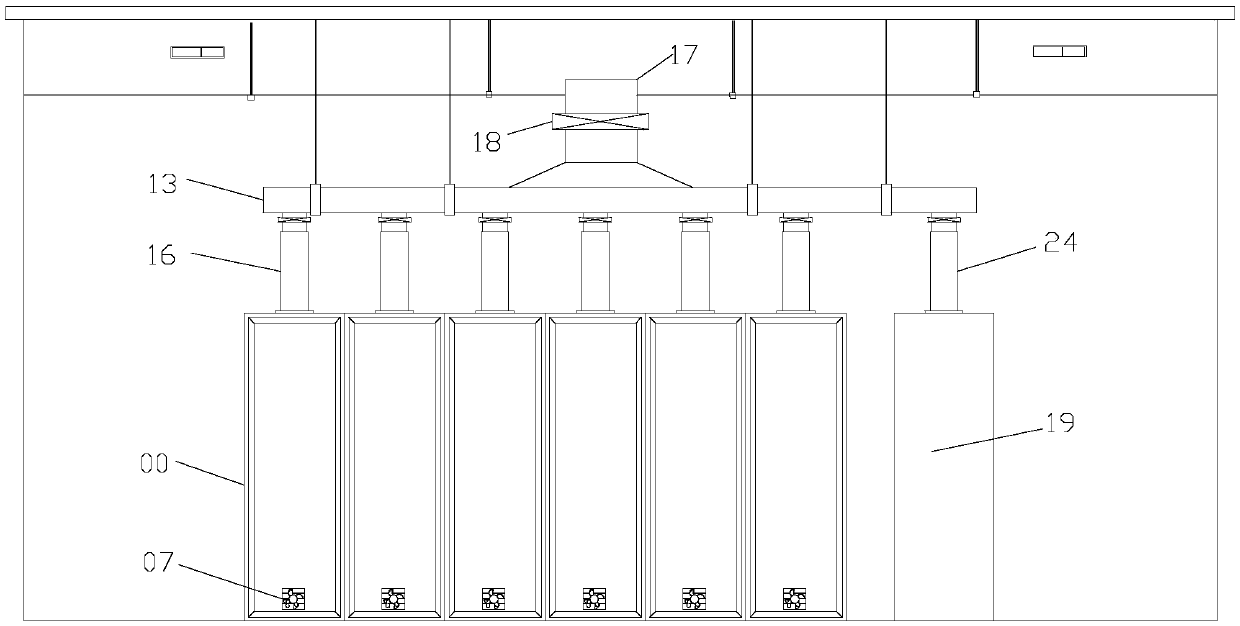

[0040] Such as figure 2 , 3 As shown, the temperature control system of the power distribution cabinet described in this embodiment includes several power distribution cabinets 00 as described in Embodiment 1 located in the power distribution room 10, the upper part of the power distribution room 10 is provided with a suspended ceiling 11, A ventilation window 12 is provided above the suspended ceiling 11; an air duct 13 is provided above the power distribution cabinet 00, and the bottom surface of the air duct 13 is provided with the same number of air outlets 14 as the power distribution cabinet 00, and the air outlet 14 is provided with ventilation Valve 15, a ventilation pipe 16 is connected between the air outlet 14 and the ventilation hole 02 of the corresponding power distribution cabinet 00; the top of the air duct 13 is provided with an exhaust pipe 17, and the outlet of the exhaust pipe 17 is located above the suspended ceiling 11 and in the row The air pipe 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com