Automated laser engraving system

A laser engraving and laser engraving machine technology, applied in welding equipment, laser welding equipment, metal processing and other directions, can solve the problems of poor working environment, eye and lung injury, and heavy labor for workers, and achieve high laser engraving efficiency. , The effect of high precision laser engraving and less worker participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

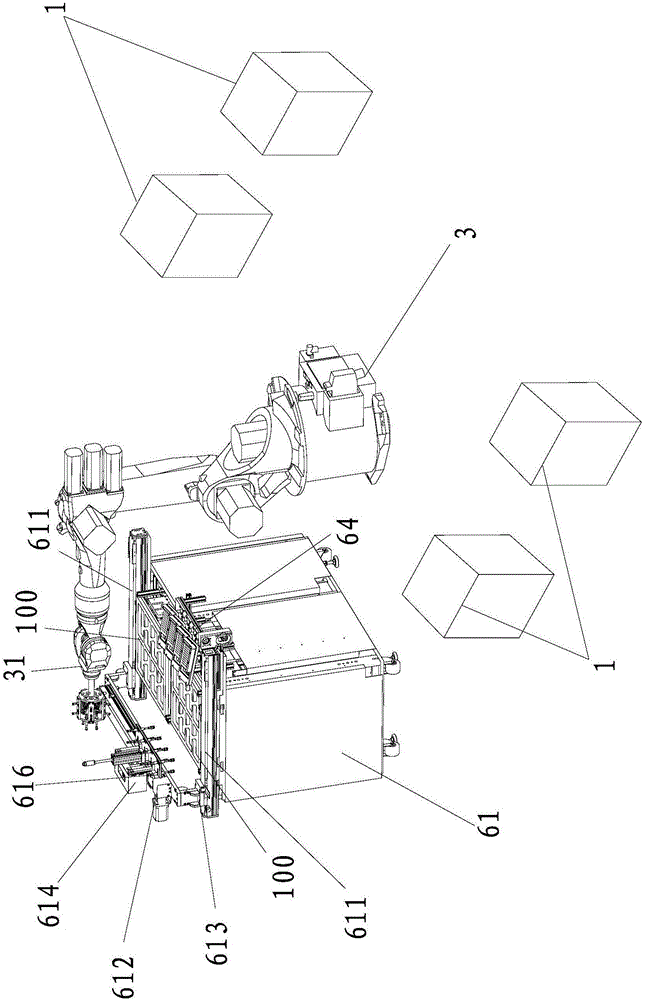

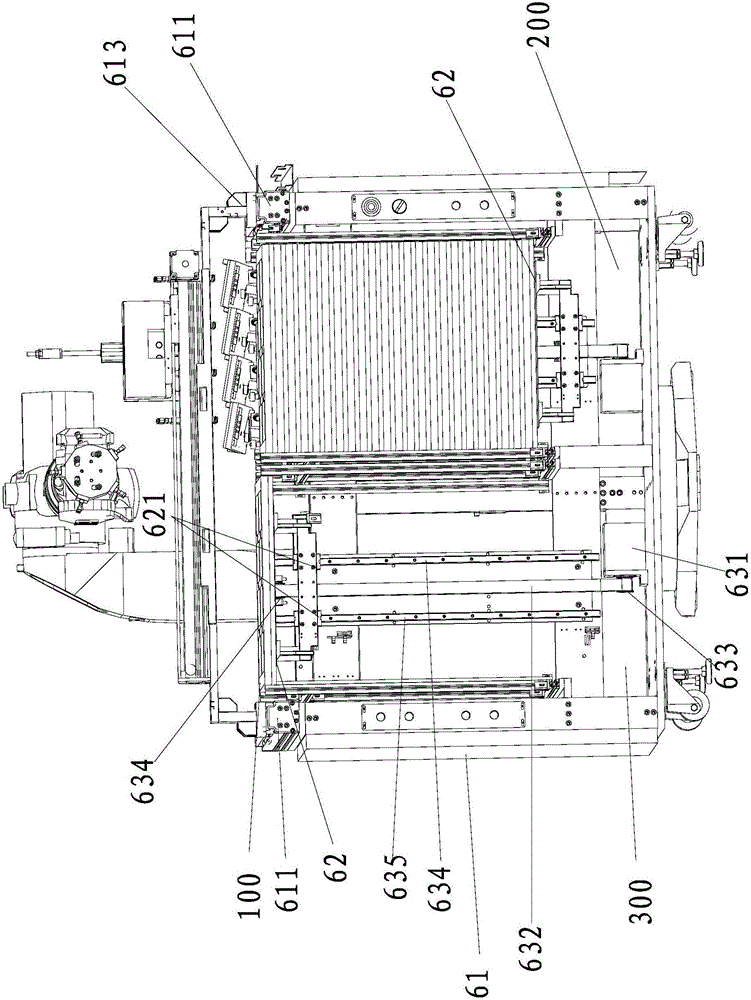

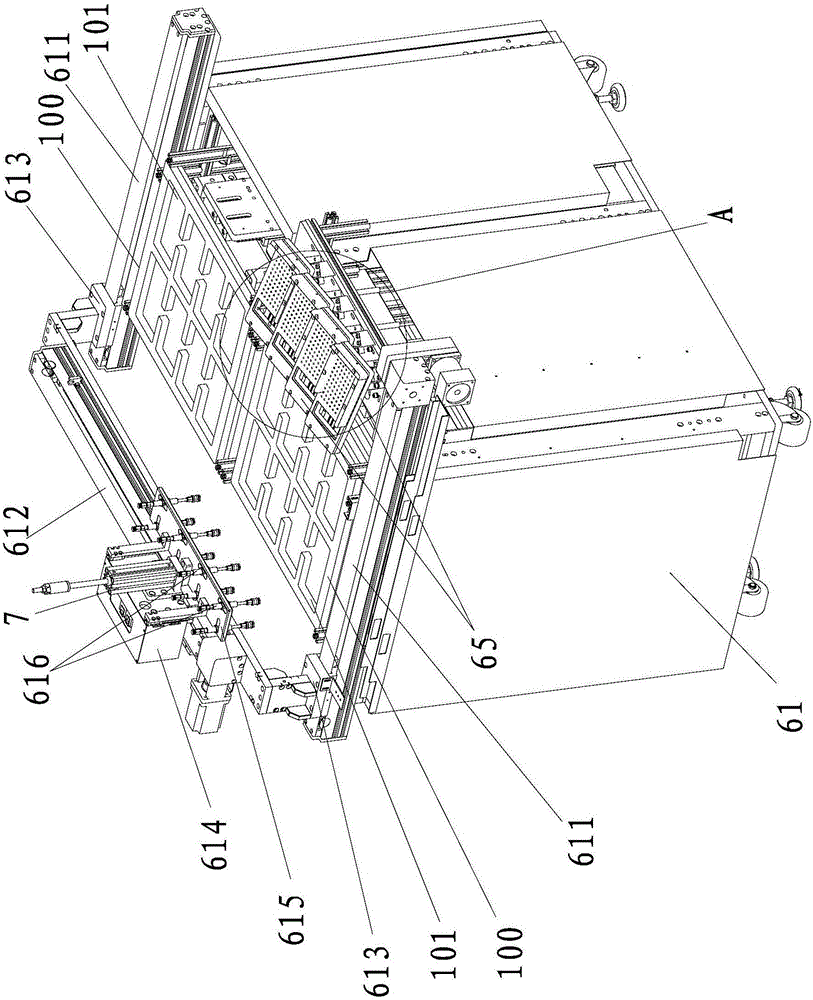

[0030] A kind of automatic laser engraving system of the present invention, as Figure 1-5 As shown, it includes a laser engraving machine 1, and also includes a suction head 2 for sucking and releasing the back cover of a mobile phone and a foam board 100, a joint robot 3 for controlling the up and down, left and right, and all-round rotation movements of the suction head 2, and a supply for A placement device on which a stack of foam boards is placed; wherein:

[0031] The suction head 2 is a columnar structure, and the peripheral surface of the suction head 2 is provided with a back cover suction and release device 4 for sucking and placing a mobile phone back cover. The arms 31 of the robot 3 are connected together, and the second axial end surface of the suction head 2 is provided with a board sucking and releasing device for sucking and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com