Production method of powdery fire-fighting grade monoammonium phosphate

A technology of monoammonium phosphate and a production method, applied in the field of phosphorus chemical industry, can solve the problems of difficult utilization of filter residues, large energy consumption, low utilization rate, etc., and achieve the effects of low production cost, energy saving and high specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) will P 2 o 5 Defluorinate 35.5% semi-aqueous wet-process phosphoric acid, filter and separate to obtain defluorinated wet-process phosphoric acid; cool the defluorinated wet-process phosphoric acid, the outlet acid temperature is 8 ° C, and age the cooled defluorinated wet-process phosphoric acid for 50 Hour;

[0028] 2) Put the aged defluorinated wet-process phosphoric acid into a neutralization tank, pass through ammonia gas for neutralization, and spray-dry the neutralized slurry at a controlled temperature of 102°C to obtain a semi-finished product of powdery fire-fighting grade monoammonium phosphate;

[0029] 3) Dry the semi-finished powdered fire-fighting grade monoammonium phosphate for the second time, and control the temperature at 85°C;

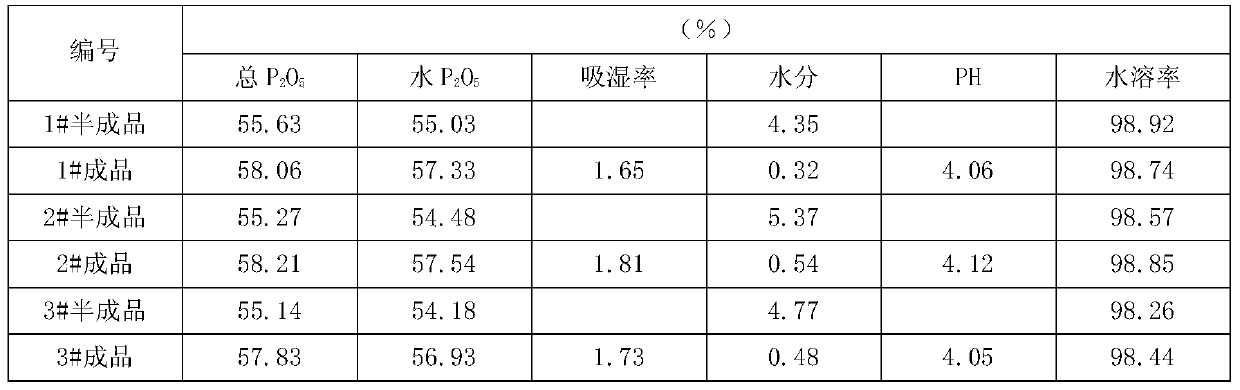

[0030] 4) Cool the secondary drying material, sieve, measure and pack, and finally obtain the finished product of powdered fire-fighting grade monoammonium phosphate. Product indicators are shown in Table 1:

[0031] ...

Embodiment 2

[0034] 1) will P 2 o 5 Defluorinate 38.7% semi-aqueous wet-process phosphoric acid, filter and separate to obtain defluorinated wet-process phosphoric acid; cool the defluorinated wet-process phosphoric acid, the acid temperature at the outlet is 12°C, and age the cooled defluorinated wet-process phosphoric acid for 28 Hour;

[0035] 2) Put the aged defluorinated wet-process phosphoric acid into a neutralization tank, pass through ammonia gas for neutralization, spray and dry the neutralized slurry, and control the temperature at 97°C to obtain a semi-finished product of powdery fire-fighting grade monoammonium phosphate;

[0036] 3) Dry the semi-finished powdered fire-fighting grade monoammonium phosphate for the second time, and control the temperature at 81°C;

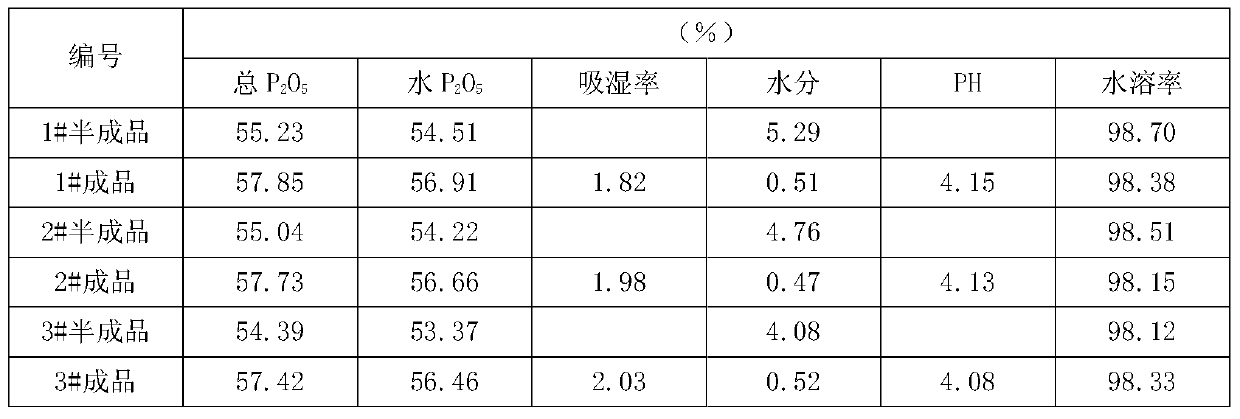

[0037] 4) Cool the secondary drying material, sieve, measure and pack, and finally obtain the finished product of powdered fire-fighting grade monoammonium phosphate. Its product indicators are shown in Table 2: ...

Embodiment 3

[0041] 1) will P 2 o 5 Defluorinate and separate 41.2% semi-aqueous wet-process phosphoric acid to obtain defluorinated wet-process phosphoric acid; cool the defluorinated wet-process phosphoric acid, the acid temperature at the outlet is 17°C, and age the cooled defluorinated wet-process phosphoric acid for 40 hours ;

[0042] 2) Put the aged defluorinated wet-process phosphoric acid into a neutralization tank, pass through ammonia gas for neutralization, spray and dry the neutralization material, and control the temperature at 100°C to obtain a semi-finished product of powdery fire-fighting grade monoammonium phosphate;

[0043] 3) Dry the semi-finished powdered fire-fighting grade monoammonium phosphate for the second time, and control the temperature at 79°C;

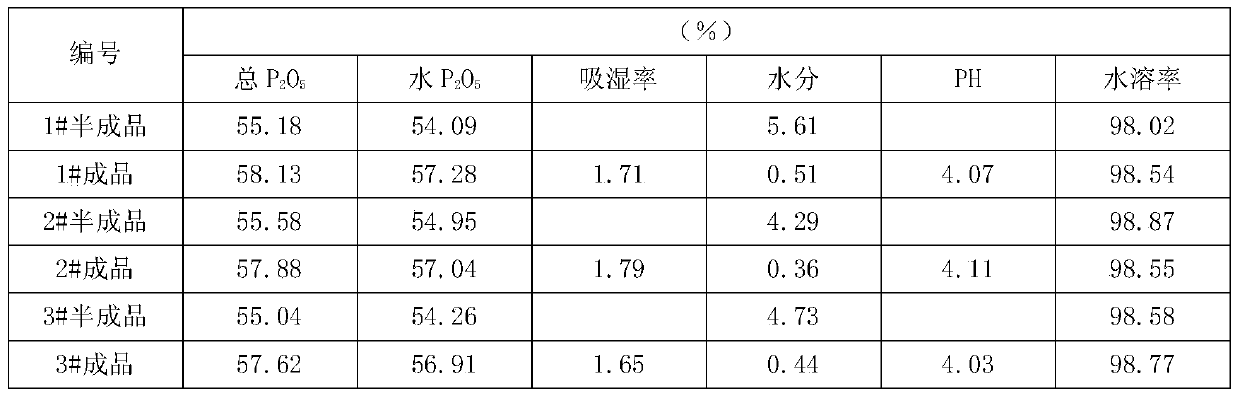

[0044] 4) Cool the secondary drying material, sieve, measure and pack, and finally obtain the finished product of powdered fire-fighting grade monoammonium phosphate. Its product indicators are shown in Table 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com