Ethylene-acrylic ester rubber product and preparation method thereof

A technology for ethylene acrylate and rubber products, which is applied in the field of ethylene acrylate rubber products and their preparation, can solve problems such as high temperature resistance and oil resistance performance of ethylene acrylate rubber, and achieves a wide service temperature range and good scorch safety. Sexual, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

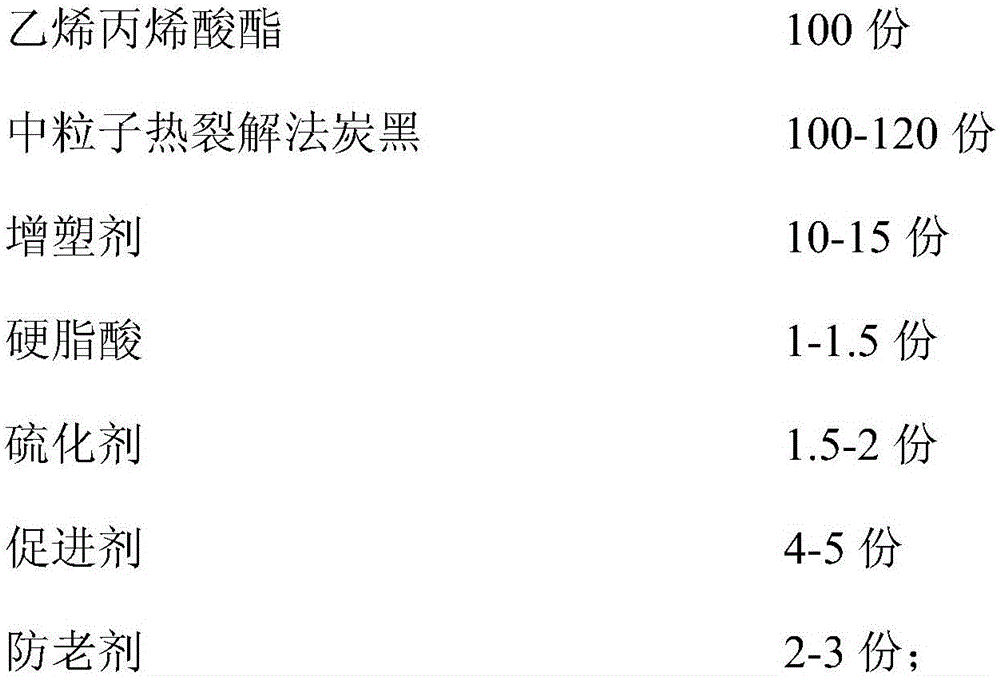

[0058] An ethylene acrylate rubber product, in parts by weight, comprising the following raw material components:

[0059]

[0060] The preparation method of above-mentioned ethylene acrylate rubber product comprises the steps:

[0061] (1) Add the raw material components of the formula amount into the internal mixer, and banbury at 70°C to obtain the mixed rubber;

[0062] (2) Add the mixed rubber into the open mill, and carry out open milling and molding at 60°C to obtain molded parts;

[0063] (3) Put the molded parts into the flat vulcanizing machine at a pressure of 190kgf / cm 2 , once vulcanized for 420s at a temperature of 170°C;

[0064] (4) Put the primary vulcanized rubber obtained in step (3) into an oven, and perform secondary vulcanization at 175° C. for 4 hours to obtain ethylene acrylate rubber products.

Embodiment 2

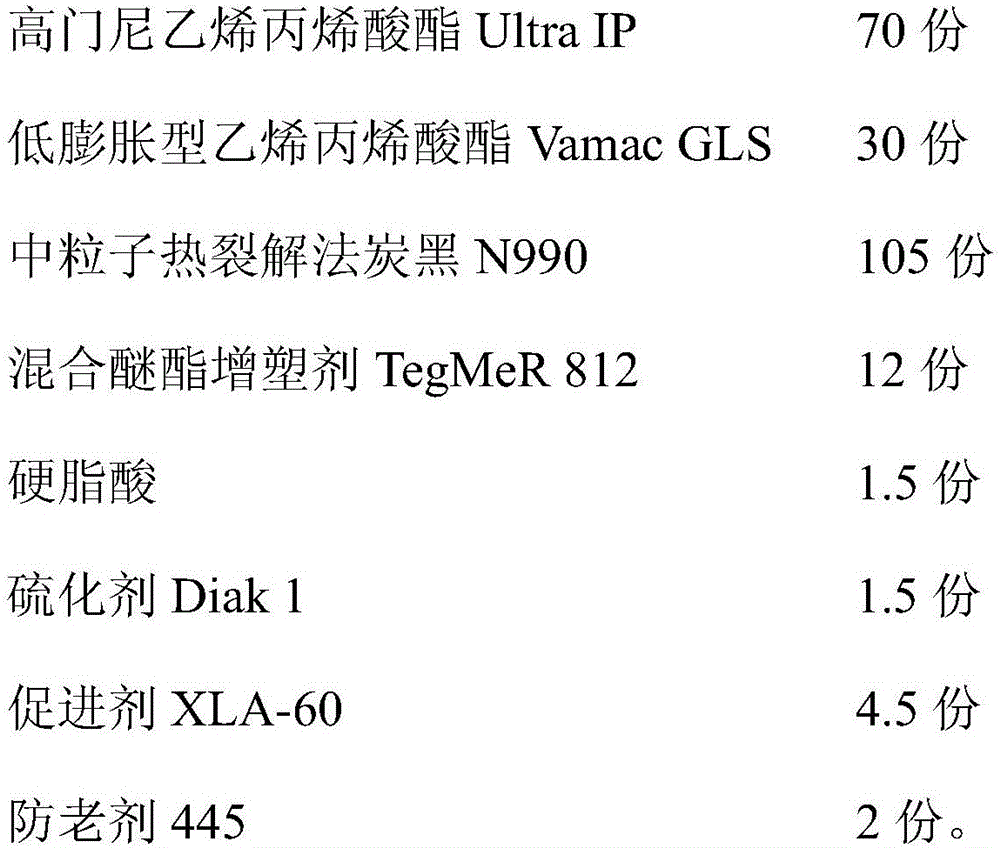

[0066] An ethylene acrylate rubber product, in parts by weight, comprising the following raw material components:

[0067]

[0068]

[0069] The preparation method of above-mentioned ethylene acrylate rubber product comprises the steps:

[0070] (1) Add the raw material components of the formula amount into the internal mixer, and banbury at 75° C. to obtain the mixed rubber;

[0071] (2) Add the rubber compound into the open mill, and carry out open mill molding at 70°C to obtain a molded part;

[0072] (3) Put the molded parts into the flat vulcanizing machine at a pressure of 170kgf / cm 2 , once vulcanized for 300s at a temperature of 180°C;

[0073] (4) Put the primary vulcanized rubber obtained in step (3) into an oven, and perform secondary vulcanization at 170° C. for 8 hours to obtain ethylene acrylate rubber products.

Embodiment 3

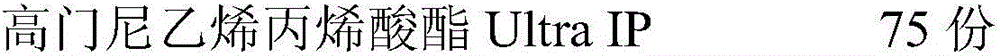

[0075] An ethylene acrylate rubber product, in parts by weight, comprising the following raw material components:

[0076]

[0077]

[0078] The preparation method of above-mentioned ethylene acrylate rubber product comprises the steps:

[0079] (1) Add the raw material components of the formula amount into the internal mixer, and banbury at 90° C. to obtain the mixed rubber;

[0080] (2) adding the mixed rubber into an open mill, and carrying out open kneading molding at 65° C. to obtain molded parts;

[0081] (3) Add the molded parts into the flat vulcanizer at a pressure of 175kgf / cm 2 , once vulcanized for 360s at a temperature of 178°C;

[0082] (4) Put the primary vulcanized rubber obtained in step (3) into an oven, and perform secondary vulcanization at 180° C. for 5 hours to obtain the ethylene acrylate rubber product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com