Hydraulic pump service life test bench

A life test, hydraulic pump technology, applied in pump test, liquid displacement machinery, machine/engine, etc., to achieve the effect of simple interface, simple operation and easy upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

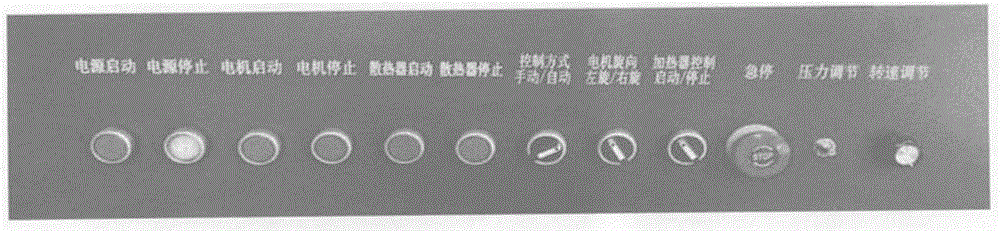

[0032] figure 1 Shown is the principle block diagram of the hydraulic pump life test bench of the present invention, and the hydraulic pump life test bench is mainly composed of a drive system, a pressure regulation system, a control system, a signal acquisition and display system, and a cooling system. The outline structure diagram and physical photos of the hydraulic pump life test bench are as follows: figure 2 with image 3 shown.

[0033] (1) Drive system

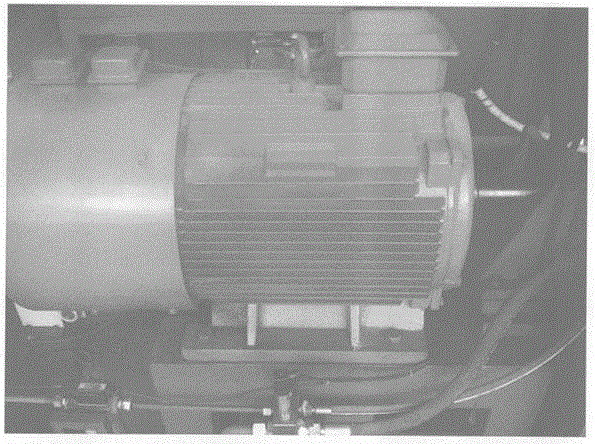

[0034] The drive system mainly includes AC variable frequency motor of model YPT-280M-2, frequency converter, coupling, mounting edge and other components, such as Figure 4 As shown, the power of the drive motor is 90KW. Under the adjustment of the frequency converter, its speed can be adjusted within the range of 0-3000r / min to meet the needs of different hydraulic pump tests.

[0035] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com