Method and system for studying mechanical properties of membrane-matrix composite structure

A technology of composite structure and mechanical properties, applied in the direction of material electrochemical variables, test material hardness, etc., can solve the problems of continuous growth, thin film cannot be zero thickness, test film-matrix composite structure can not realize the film layer, etc., to achieve uniform properties, The indentation depth is consistent and the effect of meeting the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

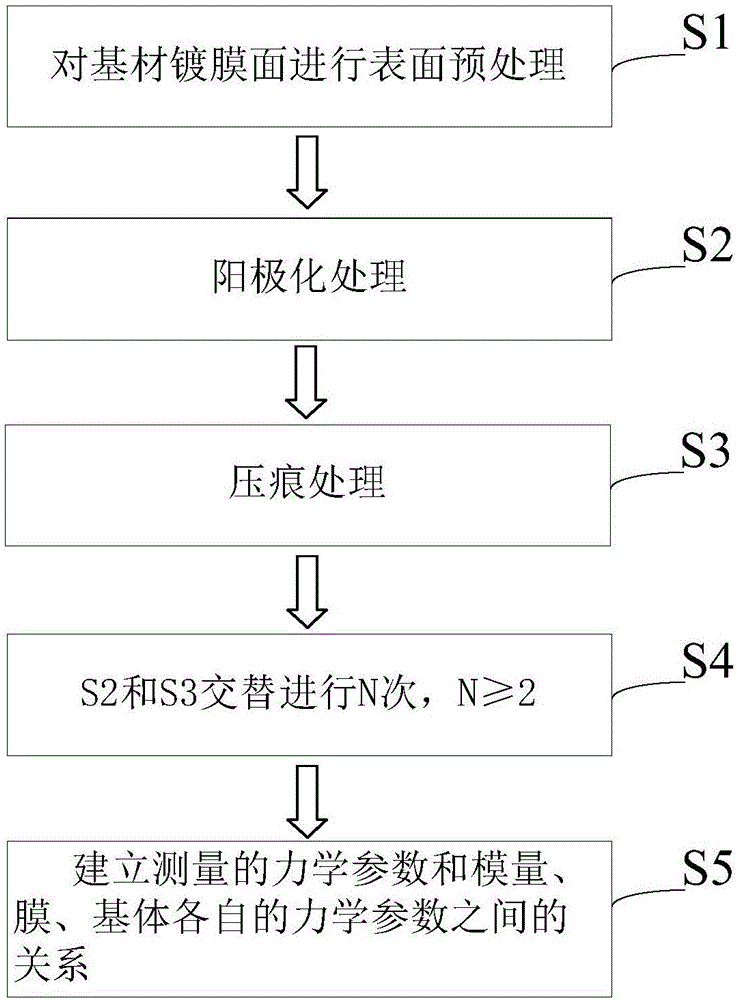

[0032] This embodiment provides a method for studying the mechanical properties of a membrane-matrix composite structure, such as figure 1 As shown, the specific steps are as follows:

[0033] S1. Surface pretreatment on the coating surface of the substrate

[0034] Clean and / or polish the coating surface of the metal or alloy substrate.

[0035] As an embodiment of the present invention, in this embodiment, the base material is metal.

[0036] S2. Anodizing treatment

[0037] The substrate to be coated is directly stacked on the positive electrode, and the first anodization treatment is carried out. The depth of the surface to be coated in the electrolyte is 3 mm to 8 mm, so that the surface to be coated starts to grow a layer of oxide film continuously at zero thickness. A polarization time is 30s ~ 90s.

[0038] As an embodiment of the present invention, in this embodiment, the depth of the surface to be coated in the electrolyte is 3mm, and the first polarization time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com