Three-way catalyst

A three-way catalyst and oxide coating technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of catalyst activity decline, Achieve the effects of inhibiting migration, avoiding alloying, and improving high temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

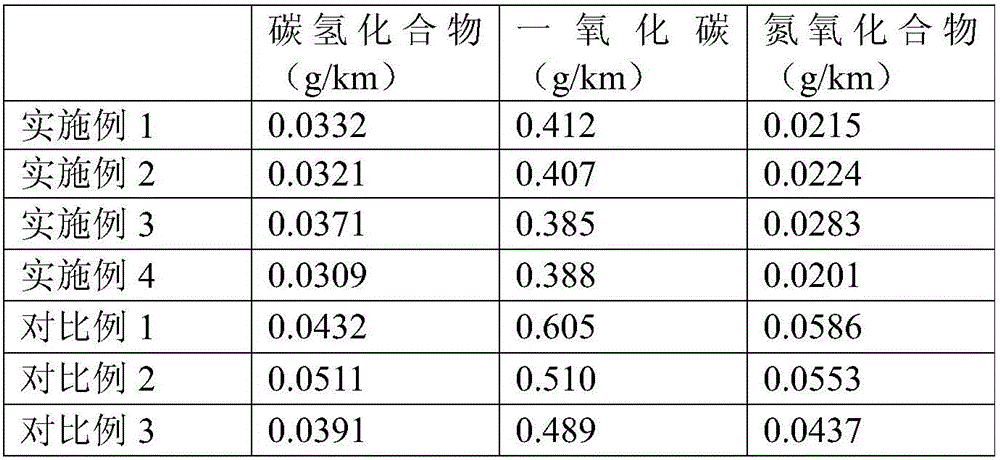

Examples

Embodiment 1

[0018] A three-way catalyst, including a honeycomb carrier with a specification of Ф101.6mm×123.3mm, a pore density of 600cpsi, a pore wall thickness of 4.3mil, and a volume of 1.0L; a lower layer of coating is attached to the honeycomb carrier, the lower layer The coating amount of the coating is 101g / L, Pd is loaded on the lower coating layer, and Pd is loaded on the cerium-zirconium solid solution, and the Pd content is 28.3g / ft 3 ; Adhere to the middle Rh coating on the lower coating, the coating amount of the middle Rh coating is 100g / L, and the content of Rh is 2.83g / ft 3 ; Attach an upper alkaline earth metal oxide coating on the middle Rh coating, the coating amount is 5g / L, and the alkaline earth metal oxide is BaO.

[0019] The preparation method of described three-way catalyst adopts the following processing steps:

[0020] (1) The coating process of the lower Pd coating: the cerium-zirconium solid solution (30wt%CeO 2 , 60wt% ZrO 2 , 5wt% La 2 o 3 and 5 wt% Y ...

Embodiment 2

[0025] A three-way catalyst, including a honeycomb carrier with a specification of Ф101.6mm×123.3mm, a pore density of 600cpsi, a pore wall thickness of 4.3mil, and a volume of 1.0L; a lower layer of coating is attached to the honeycomb carrier, the lower layer The coating amount of the coating is 101g / L, Pd is loaded on the lower coating layer, and Pd is loaded on the cerium-zirconium solid solution, and the Pd content is 28.3g / ft 3 ; Adhere to the middle Rh coating on the lower coating, the coating amount of the middle Rh coating is 100g / L, and the content of Rh is 2.83g / ft 3 ; Attach an upper alkaline earth metal oxide coating on the middle Rh coating, and the alkaline earth metal oxide is 2.5g / L of BaO and 2.5g / L of SrO.

[0026] The preparation method of described three-way catalyst adopts the following processing steps:

[0027] (1) The coating process of the lower Pd coating: the cerium-zirconium solid solution (30wt%CeO 2 , 60wt% ZrO 2 , 5wt% La 2 o 3 and 5 wt% Y ...

Embodiment 3

[0032] A three-way catalyst, including a honeycomb carrier with a specification of Ф101.6mm×123.3mm, a pore density of 600cpsi, a pore wall thickness of 4.3mil, and a volume of 1.0L; a lower layer of coating is attached to the honeycomb carrier, the lower layer The coating amount of the coating is 101g / L, Pd is loaded on the lower coating layer, and Pd is loaded on the cerium-zirconium solid solution, and the Pd content is 28.3g / ft 3 ; Adhere to the middle Rh coating on the lower coating, the coating amount of the middle Rh coating is 100g / L, and the content of Rh is 2.83g / ft 3 ; Attach an upper alkaline earth metal oxide coating on the middle Rh coating, and the alkaline earth metal oxide is BaO of 10g / L.

[0033] The preparation method of described three-way catalyst adopts the following processing steps:

[0034] (1) The coating process of the lower Pd coating: the cerium-zirconium solid solution (30wt%CeO 2 , 60wt% ZrO 2 , 5wt% La 2 o 3 and 5 wt% Y 2 o 3 ), 50g of L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com