Heparin sodium extracting method

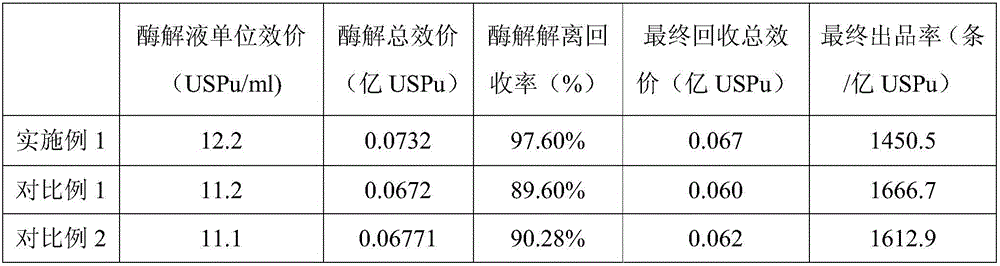

An extraction method, the technology of heparin sodium, applied in the field of heparin sodium extraction, can solve the problems of insufficient improvement in the yield of heparin sodium, unreasonable control of enzymatic hydrolysis temperature and salinity, etc., to achieve increased yield and improved enzymatic hydrolysis The effect of off-recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for extracting heparin sodium, the specific operation steps are:

[0038] 1) Preparation of pig intestinal mucosa: take each healthy pig small intestine with an average weight of 1.25kg, carefully wash with clean water to remove internal and external dirt and external skin fat, and obtain clean pig intestines, mince the clean pig intestines into mince, Pig intestinal mucosa;

[0039] 2) One-time enzymatic hydrolysis: pump the prepared pig intestinal mucosa into the enzymatic hydrolysis tank, start stirring and pump concentrated brine until the salinity is 4.2 degrees, add 2.5mol / L sodium hydroxide solution until the pH is 9.0, and obtain a mixed solution , open the heating valve, and when the mixture is heated to 33°C, add 4.2g of alkaline protease according to the amount of each pig intestine, and continue to heat up to 38°C, close the heating valve, retest the pH value, and supplement Add 2.5mol / L sodium hydroxide solution until the pH is 9.0, keep stirring ...

Embodiment 2

[0050] A method for extracting heparin sodium, the specific operation steps are:

[0051] 1) Preparation of pig intestinal mucosa: take each healthy pig small intestine with an average weight of 1.25kg, carefully wash with clean water to remove internal and external dirt and external skin fat, and obtain clean pig intestines, mince the clean pig intestines into mince, Pig intestinal mucosa;

[0052] 2) One-time enzymatic hydrolysis: pump the prepared pig intestinal mucosa into the enzymatic hydrolysis tank, start stirring and pump concentrated brine until the salinity is 4.0 degrees, add 2.2mol / L sodium hydroxide solution until the pH is 8.8, and obtain a mixed solution , open the heating valve, and when the temperature of the mixed solution is raised to 31°C, add 4g of alkaline protease according to the amount of each pig intestine, and continue to heat up to 36°C, close the heating valve, retest the pH value, and add 2.2mol / L sodium hydroxide solution to pH 8.8, heat preser...

Embodiment 3

[0063] A method for extracting heparin sodium, the specific operation steps are:

[0064] 1) Preparation of pig intestinal mucosa: take each healthy pig small intestine with an average weight of 1.25kg, carefully wash with clean water to remove internal and external dirt and external skin fat, and obtain clean pig intestines, mince the clean pig intestines into mince, Pig intestinal mucosa;

[0065] 2) One-time enzymatic hydrolysis: pump the prepared pig intestinal mucosa into the enzymatic hydrolysis tank, start stirring and pump concentrated brine until the salinity is 4.5 degrees, add 2.4mol / L sodium hydroxide solution until the pH is 9.2, and obtain a mixed solution , open the heating valve, and when the mixture is heated to 35°C, add 4.5g of alkaline protease according to the amount of each pig intestine, and continue to heat up to 40°C, close the heating valve, retest the pH value, and supplement Add 2.5mol / L sodium hydroxide solution until the pH is 9.2, heat and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com