Multifunctional tea leaves processing production line and control system thereof

A production line and tea technology, which is applied in tea processing before extraction, etc., can solve the problem that the production line cannot be produced at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and the tea processing technology that adopts, further describe the present invention in detail by embodiment, but do not limit the scope of the present invention in any way.

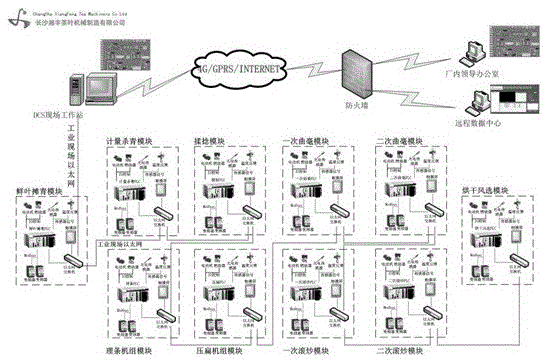

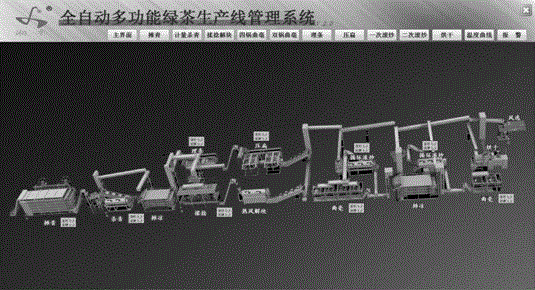

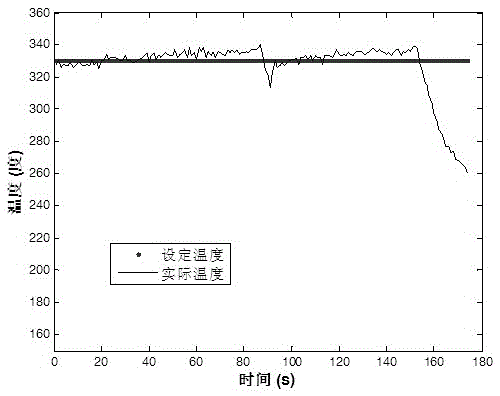

[0025] attached Figure 6 It is a schematic diagram of the process flow of the present invention, as Figure 5Shown is the overall layout of the multifunctional processing production line, specifically illustrating an implementation case of this type of multifunctional production line. The granular green tea process used in this production line is: 1. Greening → 2. Greening → 3. Cooling and regaining moisture → 4. Kneading → 5. Hot air unblocking → 6. Cooling → 7. Curling to shape → 8. Spreading Cooling and regaining moisture → 9. Shaping the koji → 10. Drying → 11. Wind selection. When producing this type of tea, the processing capacity of fresh leaves is 100kg / h, and about 630kg of dry tea can be produced in 24 hours. The fresh leaves that have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com