Pure-cocoa-butter-chocolate-coating high protein bar and preparation method thereof

A chocolate-coated, high-protein technology, applied in cocoa, food ingredients as taste improvers, food science, etc., can solve the problem of protein content in discolored protein bars, and achieve the effect of not easy browning and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

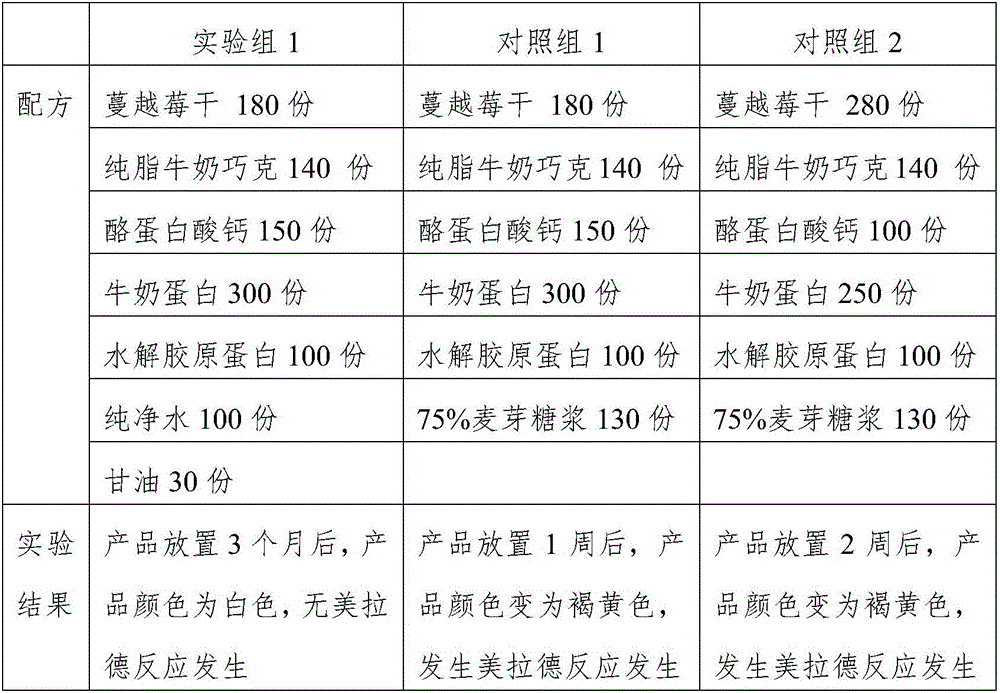

Embodiment 1

[0035] The ratio of pure milk chocolate coated high protein bar in this embodiment is as follows: 180 parts of dried cranberries, 140 parts of pure milk chocolate, 150 parts of calcium caseinate, 300 parts of milk protein, 100 parts of hydrolyzed collagen, pure 100 parts of water, 30 parts of glycerin.

[0036] The preparation method of the pure fat milk chocolate coating high protein bar of the present embodiment is as follows:

[0037] (1) Melting of pure milk chocolate: melt the pure milk chocolate to about 45°C in water, and the water temperature is 50°C;

[0038] (2) Tempering of pure milk chocolate: cool down the melted pure milk chocolate to 28°C, then heat up to 30°C for later use;

[0039] (3) Treatment of dried cranberry fruit: separate the dried cranberry fruit that sticks together, and remove debris and cranberry seeds with a sieve;

[0040] (4) Material weighing: weigh a certain amount of dried cranberries, calcium caseinate, milk protein, and hydrolyzed collage...

Embodiment 2

[0044] The ratio of pure milk chocolate coated high protein bar in this embodiment is as follows: 300 parts of dried cranberries, 500 parts of pure milk chocolate, 600 parts of calcium caseinate, 500 parts of milk protein, 500 parts of hydrolyzed collagen, pure 200 parts of water, 100 parts of glycerin.

[0045] The preparation method of the high-protein bar coated with pure fat milk chocolate in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0047] The ratio of pure milk chocolate coated high protein bar in this embodiment is as follows: 100 parts of dried cranberries, 100 parts of pure milk chocolate, 100 parts of calcium caseinate, 100 parts of milk protein, 50 parts of hydrolyzed collagen, pure 50 parts of water, 10 parts of glycerin.

[0048] The preparation method of the high-protein bar coated with pure fat milk chocolate in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com