Room-temperature vaporizing and sterilizing system

A disinfection and room temperature technology, applied in the field of sanitation and disinfection, can solve the problems of hydrogen peroxide vapor superheated decomposition, condensation, short residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present application is described in detail below in conjunction with the examples, but the present application is not limited to these examples.

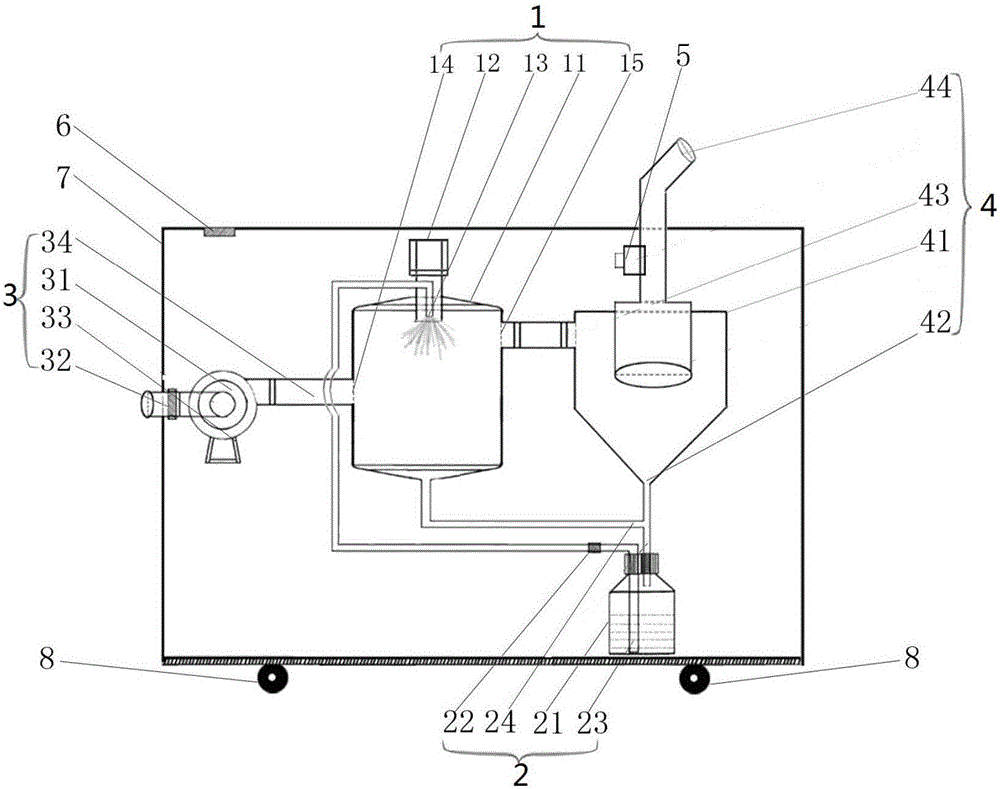

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a room temperature vaporization disinfection and sterilization system. The room temperature vaporization disinfection and sterilization system includes a liquid storage system 2 storing a disinfectant, an atomizer for atomizing the disinfectant Separation system 1, a drive system 3 for providing power to the atomization separation system 1, a vaporization separation system 4 for separating and vaporizing the atomized disinfectant, the drive system 3 is separated from the atomization System 1 and the vaporization separation system 4 are connected in sequence, the liquid storage system 2 is respectively connected with the atomization separation system 1 and the vaporization separation system 4, and the liquid storage system 2 is used to The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com