A kind of hydroformylation reaction method and catalyst using rhodium ruthenium double metal and tetradentate phosphine ligand

A technology of catalysts and phosphine ligands, which is applied in the direction of physical/chemical process catalysts, catalytic reactions, organic compounds/hydrides/coordination complex catalysts, etc. It can solve the problems of low aldehyde product positive-to-isotropic ratio and achieve high conversion rate , Large industrial application value, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

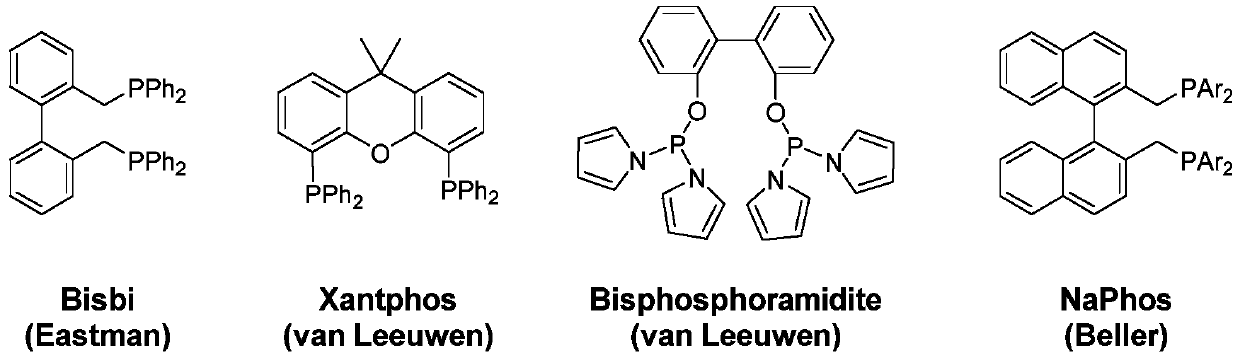

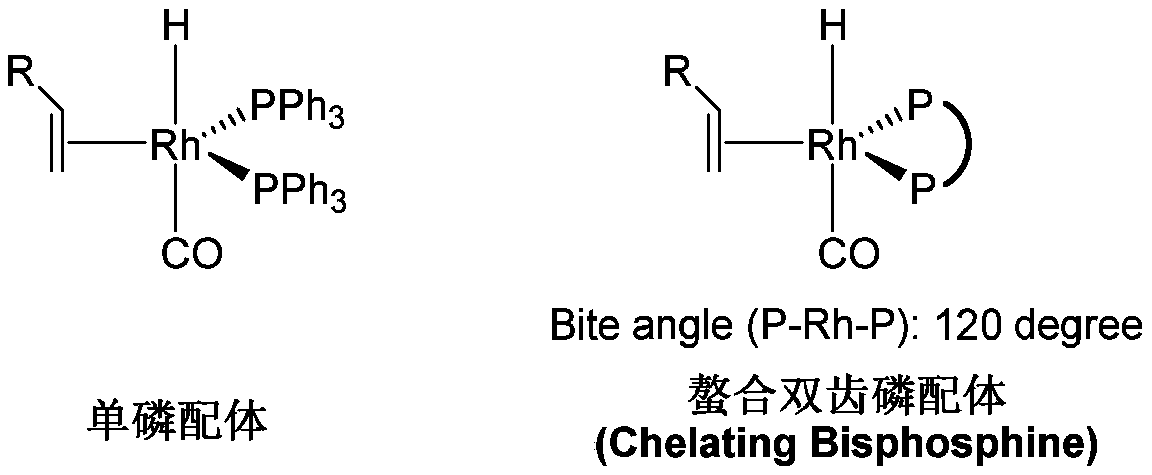

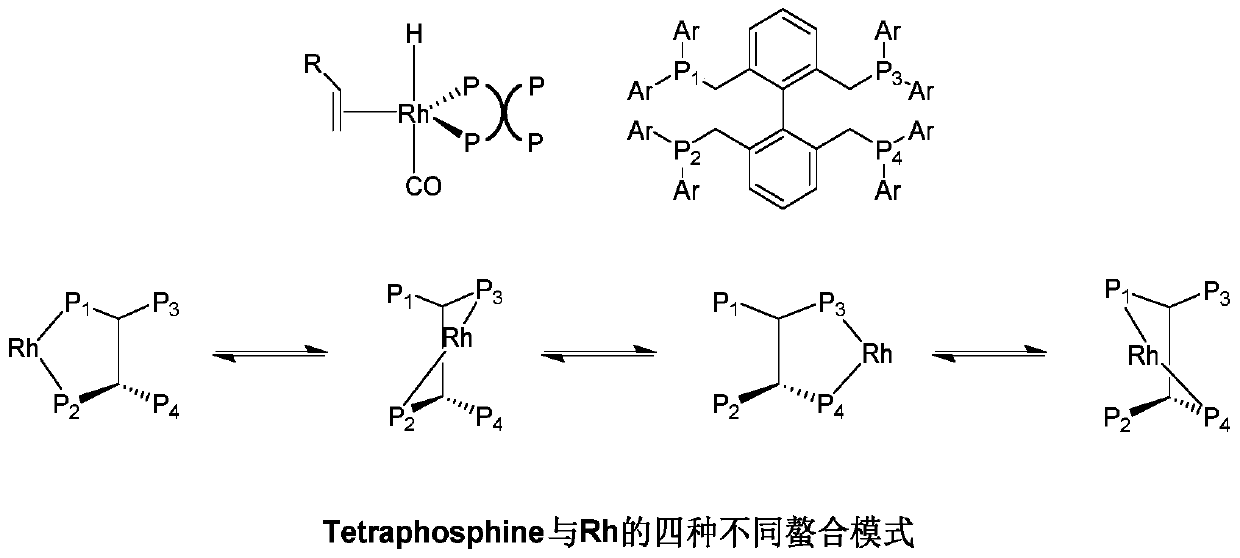

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: adopt rhodium ruthenium bimetallic (Rh(acac)(CO) 2 , RuH(Cl)(PNN)(CO)) and biphenyl triphosphine ligand (Tribi) with rhodium ruthenium bimetallic (Rh(acac)(CO) 2 , RuH(Cl)(PNN)(CO)) and biphenyl tetraphosphine ligand (Tetrabi) isomerization and hydroformylation (S / C=2000, S / C is the molar ratio of reactant to catalyst )

[0040] Rh,Ru+Tribi: Weighing the rhodium catalyst Rh(acac)(CO) in the glove box 2 (5.2mg, 0.02mmol), 2,2', 6-three (diphenylphosphinomethyl)-1,1'-biphenyl (Tribi) (60mg, 0.08mmol) into the complexing bottle, and then remove Oxygen / water dichloromethane (Dichloromethane, 2.65g, 31.2mmol) solvent was placed in the bottle, and stirred to dissolve to form a complex solution of rhodium and biphenyltriphosphine ligand. Subsequently, the ruthenium catalyst RuH(Cl)(PNN)(CO) (9.8mg, 0.02mmol) was weighed in the glove box, added to the complexed rhodium catalyst solution, stirred at room temperature to dissolve it. Put the autoclave into the g...

Embodiment 2

[0045] Embodiment 2: adopt rhodium ruthenium bimetallic (Rh(acac)(CO) 2 , RuH(Cl)(PNN)(CO)) and biphenyl triphosphine ligand (Tribi) with rhodium ruthenium bimetallic (Rh(acac)(CO) 2 , RuH(Cl)(PNN)(CO)) and biphenyl tetraphosphine ligand (Tetrabi) isomerization and hydroformylation (S / C=4000)

[0046] Rh,Ru+Tribi: Weighing the rhodium catalyst Rh(acac)(CO) in the glove box 2 (2.6mg, 0.01mmol), 2,2',6-three (diphenylphosphine methyl)-1,1'-biphenyl (Tribi) (30mg, 0.04mmol) into the complexing bottle, and then remove Oxygen / water dichloromethane (Dichloromethane, 2.65g, 31.2mmol) solvent was placed in the bottle, and stirred to dissolve to form a complex solution of rhodium and biphenyltriphosphine ligand. Subsequently, the ruthenium catalyst RuH(Cl)(PNN)(CO) (4.9 mg, 0.01 mmol) was weighed in the glove box, added to the complexed rhodium catalyst solution, and stirred at room temperature to dissolve it. Put the autoclave into the glove box, pipette 100 μl of complexed rhodiu...

Embodiment 3

[0051] Embodiment 3: adopt rhodium ruthenium bimetallic (Rh(acac)(CO) 2 , RuH(Cl)(PNN)(CO)) and biphenyl triphosphine ligand (Tribi) with rhodium ruthenium bimetallic (Rh(acac)(CO) 2 , RuH(Cl)(PNN)(CO)) and biphenyl tetraphosphine ligand (Tetrabi) isomerization and hydroformylation (S / C=10000)

[0052] Rh,Ru+Tribi: Weighing the rhodium catalyst Rh(acac)(CO) in the glove box 2 (2.6mg, 0.01mmol), 2,2',6-three (diphenylphosphine methyl)-1,1'-biphenyl (Tribi) (30mg, 0.04mmol) into the complexing bottle, and then remove Oxygen / water dichloromethane (Dichloromethane, 6.63g, 78.0mmol) solvent was put into the bottle, and stirred to dissolve to form a complex solution of rhodium and biphenyltriphosphine ligand. Subsequently, the ruthenium catalyst RuH(Cl)(PNN)(CO) (4.9 mg, 0.01 mmol) was weighed in the glove box, added to the complexed rhodium catalyst solution, and stirred at room temperature to dissolve it. Put the autoclave into the glove box, pipette 100 μl of complexed rhodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com