Generation method of phononic crystal beam coupling vibration band gap based on route guidance

A phononic crystal and path-guiding technology, which is applied in the direction of the fluid using vibration, can solve the problems of large differences in the prohibition effect and inconsistent prohibition effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

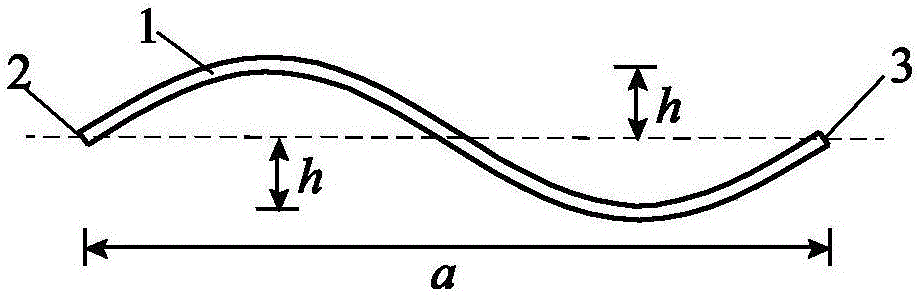

[0017] Such as figure 1 As shown, take a straight beam of a certain length and bend it on a certain plane, and the method is not limited to construct a beam element in the shape of a sine wave. That is, the axis of the beam body 1 has a sinusoidal waveform. The half-height of the beam element is recorded as h, the length is recorded as a, the value range of a is 0.000001-10m, and the range of h / a is 0.001-10.

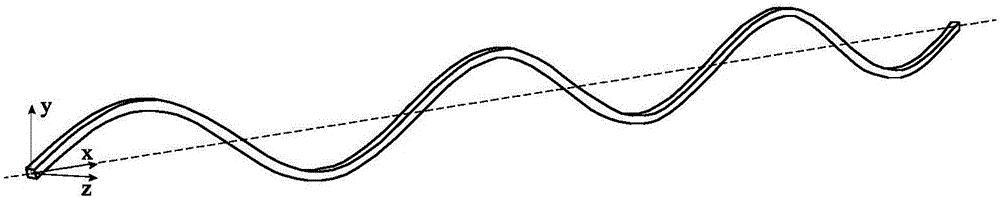

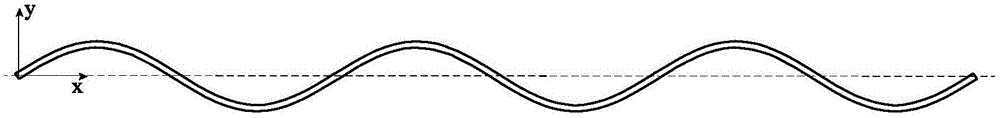

[0018] The bending wave and longitudinal wave that can be propagated in the axis projection plane of the sinusoidal wave beam must propagate along the sinusoidal wave path, and the wave propagation path changes in a sinusoidal wave shape, so the bending wave component and longitudinal wave component of the total wave propagating in the beam will travel along the The curved propagation paths are constantly transforming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com