Liquid lifting pipe for conveying molten metal for casting and casting mold applying liquid lifting pipe

A technology for casting molds and molten metal, applied in the field of liquid risers, can solve the problems of short service life, easy damage, and unsatisfactory heat preservation effect of the liquid riser, so as to reduce heat loss, prolong service life, and simplify the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

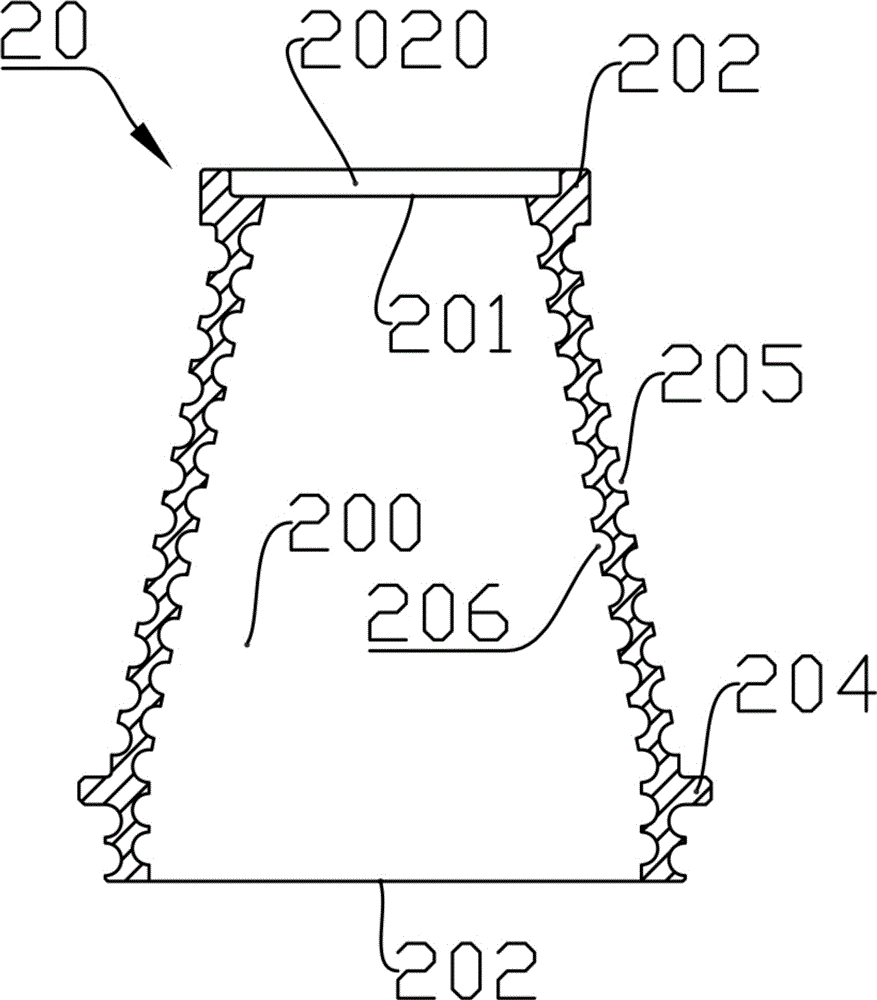

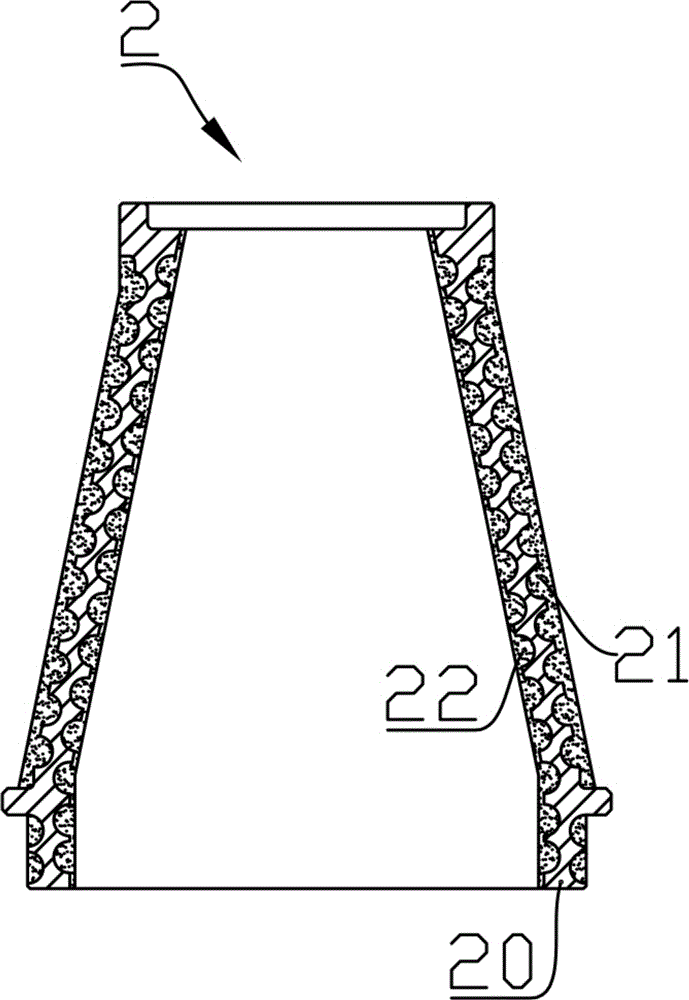

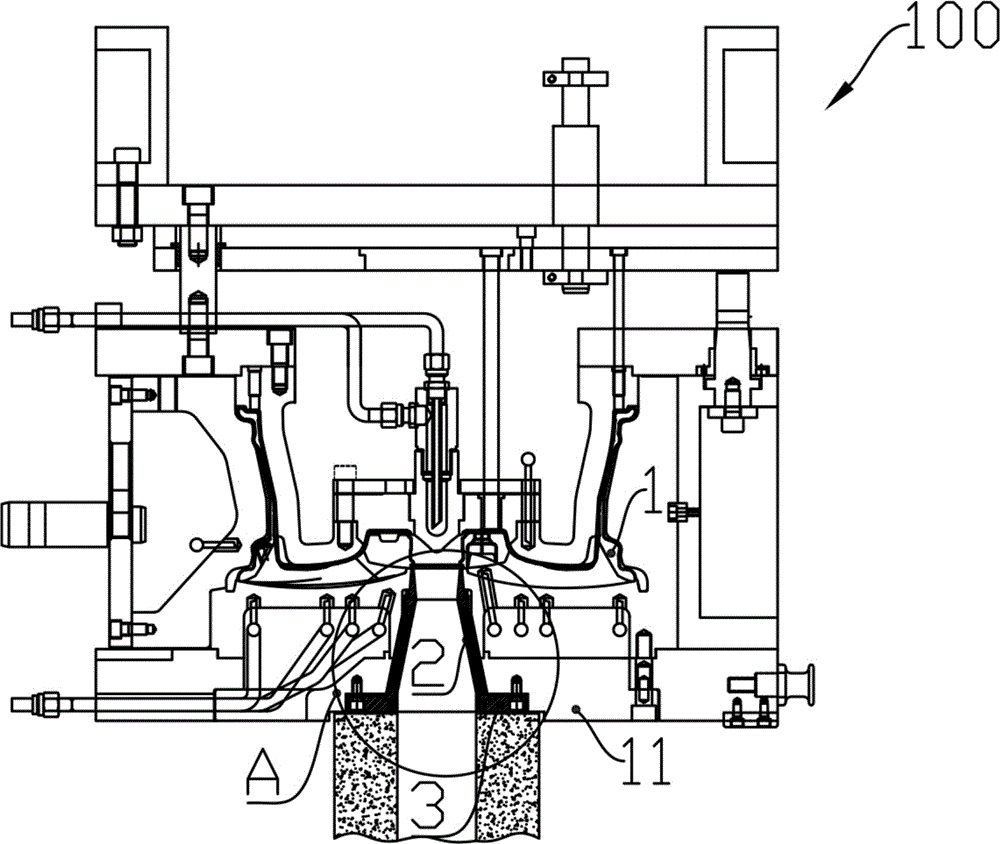

[0024] Such as figure 1 with figure 2Shown is a liquid riser 2 for transporting molten metal, the liquid riser 2 includes a substantially tubular frame body 20, and outer and inner surfaces of the frame body 20 are respectively coated with outer thermal insulation coating 21 and inner thermal insulation coating 22; the mechanical strength of the skeleton body 20 is greater than the mechanical strength of the outer thermal insulation coating 21 and the inner thermal insulation coating 22; the outer thermal insulation coating 21 and the inner thermal insulation coating 22 It is a thermal insulation mineral mixture, which includes alumina, talc, mica, diatomaceous earth and titanium oxide.

[0025] The structure of the liquid riser applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the skeleton body 20 is roughly tubular, and an upper tube hole 201 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com