Riser tube and method of manufacturing the same

A manufacturing method and liquid riser technology are applied in the structure and manufacturing field of liquid risers for low-pressure casting aluminum alloy gear boxes, which can solve the problems of narrow space for increasing Fe, problems of batch quality, hindering the increase of Fe in molten aluminum, and achieve anti-excitation Good cold shock and heat performance, solve the problem of iron increase, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

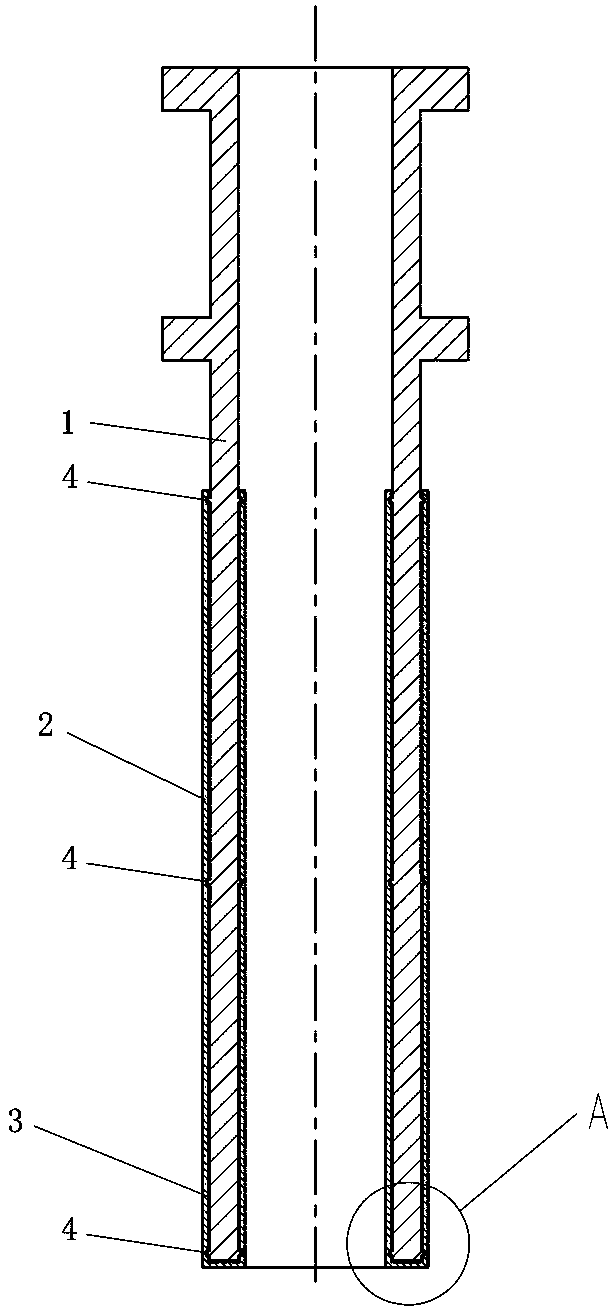

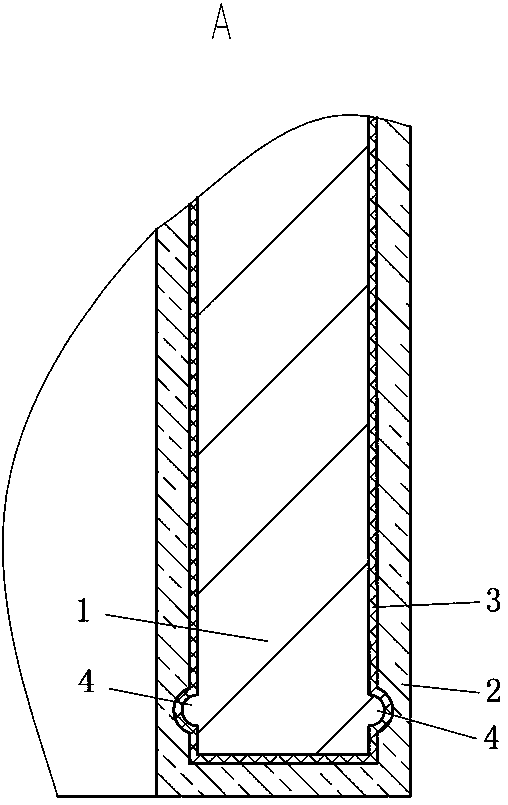

[0018] Such as figure 1 , 2 As shown, a riser pipe of the present invention includes an iron riser pipe 1, a ceramic protective sleeve 2 and a refractory cotton transition layer 3, and the refractory cotton transition layer 3 is wrapped on the iron riser pipe 1 , the ceramic protective sleeve 2 is coated on the refractory wool transition layer 3 .

[0019] Such as figure 1 , 2 As shown, the inner and outer pipe walls of the iron liquid riser 1 have fixed bosses 4, and the fire-resistant cotton transition layer 3 is fixed on the fixed bosses 4.

[0020] Such as figure 1 , 2 As shown, there are three fixing bosses 4 on the inner and outer pipe walls of the iron riser pipe 1 at an axial height, and they are evenly distributed along the circumference of the iron riser pipe 1 .

[0021] It is also possible that there are three fixed bosses 4 on the inner and outer pipe walls of the iron liquid riser 1 at three axial heights, and they are evenly distributed along the circumfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com