Working fluid tank door for large-sized electrical discharge machining tool

A technology of electric discharge machine tool and working liquid tank, which is applied in the direction of electric processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of heavy weight of the liquid tank door, achieve small operating space, reduce energy consumption, and facilitate opening and closing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

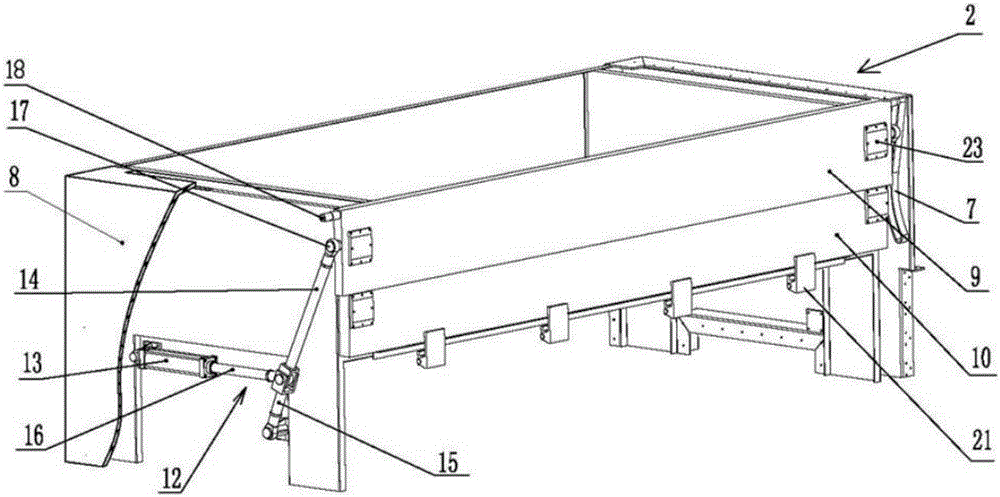

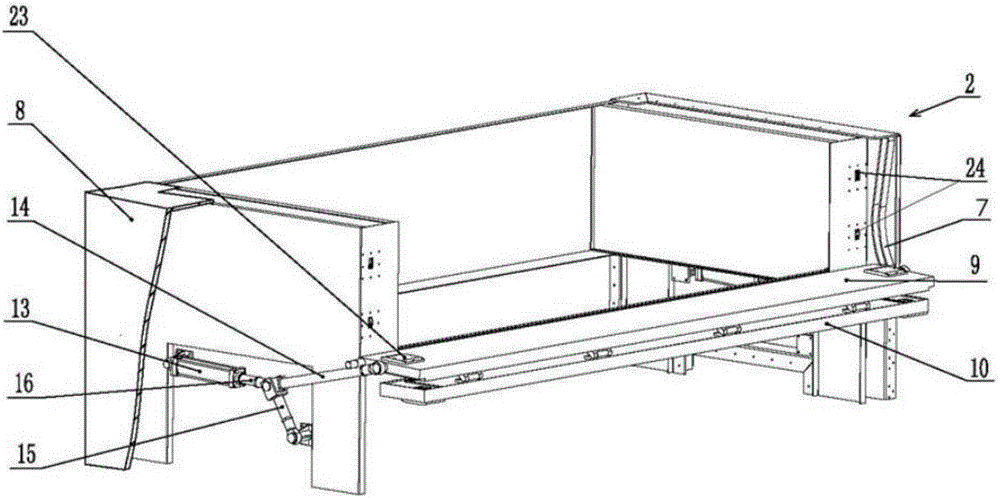

[0027] Below in conjunction with accompanying drawing, the embodiment of the present invention is described further: see figure 1 , figure 2 , the working fluid tank 2 of the large electric discharge machine tool is set on the base of the machine tool, and the workbench of the machine tool is placed in the working fluid tank 2 . The volume of the working liquid tank 2 is very large, especially the die dimension is very large.

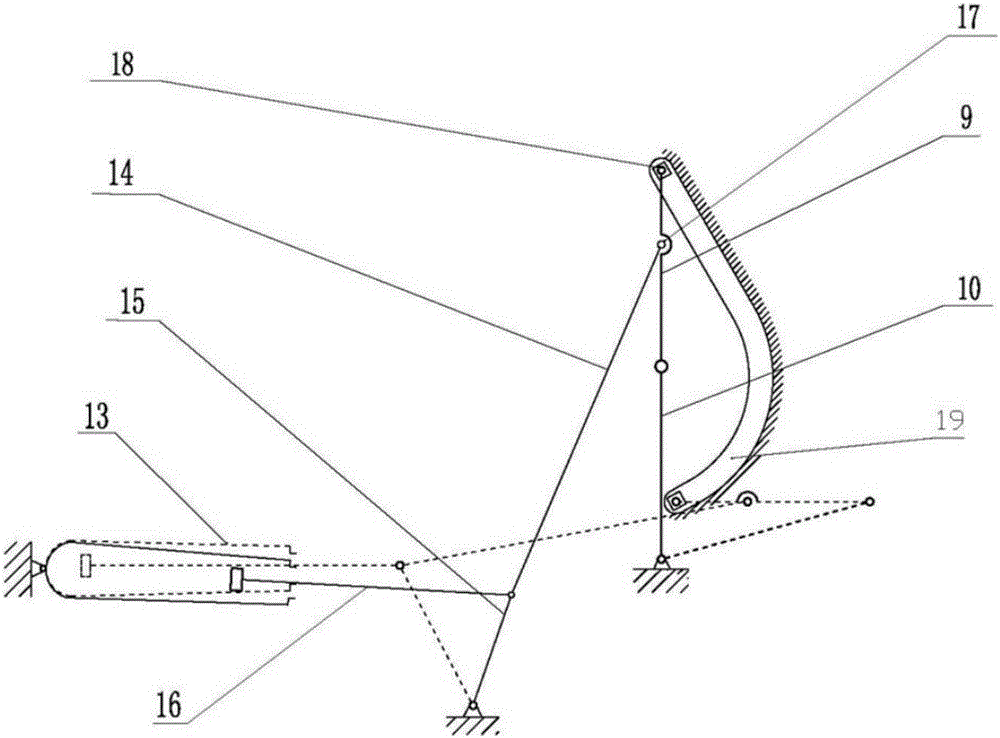

[0028] The working liquid tank 2 consists of a liquid tank body 5, two inner wall panels 6, two outer guard plates 8, two guide plates 7 fixedly installed on the inner sides of the two outer guard plates 8, It consists of a liquid tank door 11 hinged by an upper door 9 and a lower door 10 and a hydraulic drive mechanism 12 .

[0029] Because the longitudinal length of the liquid tank body 5 is too long, and the rear wall is undoubtedly the weakest link in the pressure bearing capacity of the working liquid tank 2, an auxiliary pressure-bearing mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com