A time -based powder -based powder and particle material should be given

A granular material and powder technology, applied in the field of on-demand feeding of powder and granular materials based on time regulation, can solve problems that have not been able to further in-depth research, achieve the effect of reducing waste and improving the accuracy of powder dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

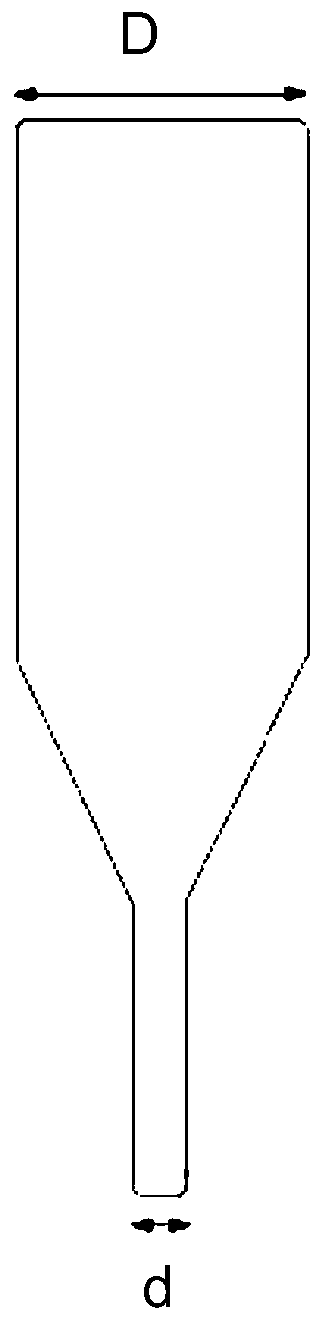

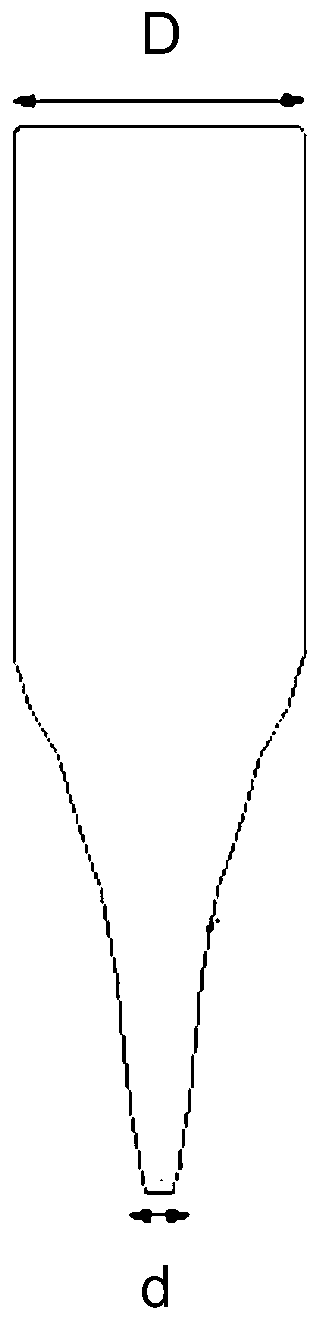

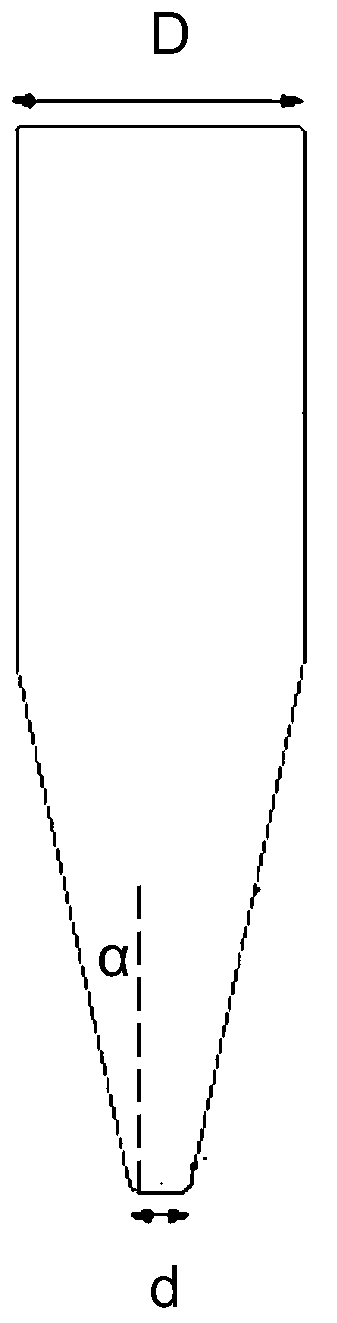

[0030] The powder and granular material feeding method based on time regulation of the present invention adopts such as Figure 2 ~ Figure 4 The micro-feeder shown mainly includes a material storage and feeding pipe 1 and a mechanical vibration source 2. The material storage and feeding pipe 1 includes a funnel-shaped inlet flow channel 11 connected sequentially from top to bottom, a round straight The tubular flow channel 12 and the conical outlet flow channel 13, the lower end of the funnel-shaped inlet flow channel 11 is connected to the upper end of the circular straight tubular flow channel 12, and the inner diameter of the lower end of the funnel-shaped inlet flow channel 11 is the same as the inner diameter of the circular straight tubular flow channel 12 , the lower end of the circular straight tubular flow channel 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com