Method for regulating and controlling three-dimensional graphene holes with aid of sulfur used as template

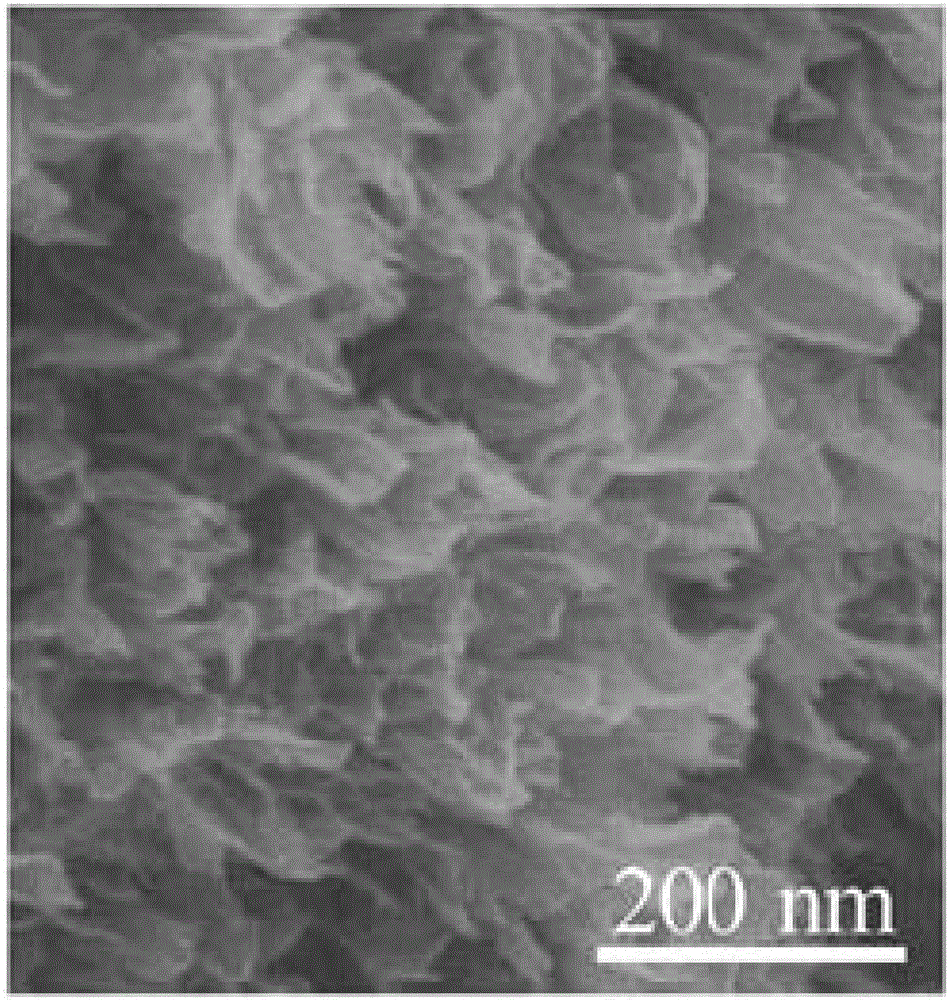

A graphene, three-dimensional porous technology, applied in the field of graphene, can solve the problems of limited size, poor thermal stability, limited range, etc., achieve the effect of mild conditions, simple operation, and control of pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for using sulfur as a template to regulate three-dimensional graphene pores, at least including the following steps:

[0033] In the first step, take 78.5mL of 2mg / mL graphene oxide dispersion and place it in a 100mL beaker, add 0.75gNa 2 S 2 o 3 ·5H 2 0, then add 6.5mL of 1M hydrochloric acid, stir for 30min to make it fully mixed, to obtain a mixed dispersion;

[0034] In the second step, the mixed dispersion liquid obtained in the first step is added to a 100mL hydrothermal reaction kettle for hydrothermal reaction. the hydrogel;

[0035] The third step is to fully soak the hydrogel obtained in the second step in deionized water to remove impurities, and then fully dry it at 70°C for 48 hours to remove water and obtain the product to be treated;

[0036] The fourth step is to desulfurize the product to be treated obtained in the third step. Specifically, under the protection of argon, the temperature is raised to 400°C at a heat...

Embodiment 2

[0041] This embodiment provides a method for using sulfur as a template to regulate three-dimensional graphene pores, at least including the following steps:

[0042] In the first step, take 83.5mL of 2mg / mL graphene oxide dispersion and place it in a 100mL beaker, add 0.10gNa 2 S 2 o 3 ·5H 2 0, then add 1.5 mL of 1M hydrochloric acid, stir for 30 min to make it fully mixed, and obtain a mixed dispersion;

[0043] In the second step, the mixed dispersion liquid obtained in the first step is added to a 100mL hydrothermal reaction kettle for hydrothermal reaction. the hydrogel;

[0044] The third step is to fully soak the hydrogel obtained in the second step in deionized water to remove impurities, and then fully dry it at 75°C for 40 hours to remove water and obtain the product to be treated;

[0045] The fourth step is to desulfurize the product to be treated obtained in the third step. Specifically, under the protection of argon, the temperature is raised to 420°C at a h...

Embodiment 3

[0047] This embodiment provides a method for using sulfur as a template to regulate three-dimensional graphene pores, at least including the following steps:

[0048] In the first step, take 82.5mL of 1.5mg / mL graphene oxide dispersion and place it in a 100mL beaker, add 0.21gNa 2 S 2 o 3 ·5H 2 0, then add 2.5 mL of 1M hydrochloric acid, stir for 40 min to make it fully mixed, and obtain a mixed dispersion;

[0049] In the second step, the mixed dispersion liquid obtained in the first step is added to a 100mL hydrothermal reaction kettle for hydrothermal reaction. the hydrogel;

[0050] The third step is to fully soak the hydrogel obtained in the second step in deionized water to remove impurities, and then fully dry it at 85°C for 30 hours to remove water and obtain the product to be treated;

[0051] The fourth step is to desulfurize the product to be treated obtained in the third step. Specifically, under the protection of argon, the temperature is raised to 350°C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com