Method for activating and improving surface loading quantity of nanometer silicon negative electrode of lithium ion battery by employing sulfur template and hydrogen peroxide

A lithium-ion battery and nano-silicon technology, which is applied in the direction of battery electrodes, active material electrodes, nanotechnology for materials and surface science, etc., can solve the problems of limiting lithium ion transmission and limitation, to ensure ion transmission, prevent powder Melting and agglomeration, to achieve the effect of dense shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for increasing the surface loading of nano-silicon negative electrodes of lithium-ion batteries by using sulfur templates and hydrogen peroxide activation, which at least includes the following steps:

[0036] In the first step, take 28.5mL of 4mg / mL graphene oxide dispersion and place it in a 100mL beaker, add 3.41gNa 2 S 2 o 3 ·5H 2 0, then add 1M hydrochloric acid 28mL, stir 30min to make it fully mix, obtain mixed dispersion liquid;

[0037] In the second step, take 28.5 mL of absolute ethanol, add 57 mg of nano-silicon, and sonicate for 20 minutes to obtain a uniform dispersion;

[0038] In the third step, mix the dispersion liquid obtained in the first step and the second step, and then sonicate again for 20 minutes, and then add 500 μL of 30% hydrogen peroxide solution into a 100 mL hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction 180°C, the duration of the hydrothermal reac...

Embodiment 2

[0045] The difference with embodiment 1 is:

[0046] The consumption of graphene oxide dispersion liquid is adjusted to 36mL, Na 2 S 2 o 3 ·5H 2 The amount of O was adjusted to 1.63g, the amount of hydrochloric acid was adjusted to 13mL, the amount of absolute ethanol was adjusted to 36ml, and the amount of nano-silicon was adjusted to 72mg. The rest are the same as in Example 1, and will not be repeated here.

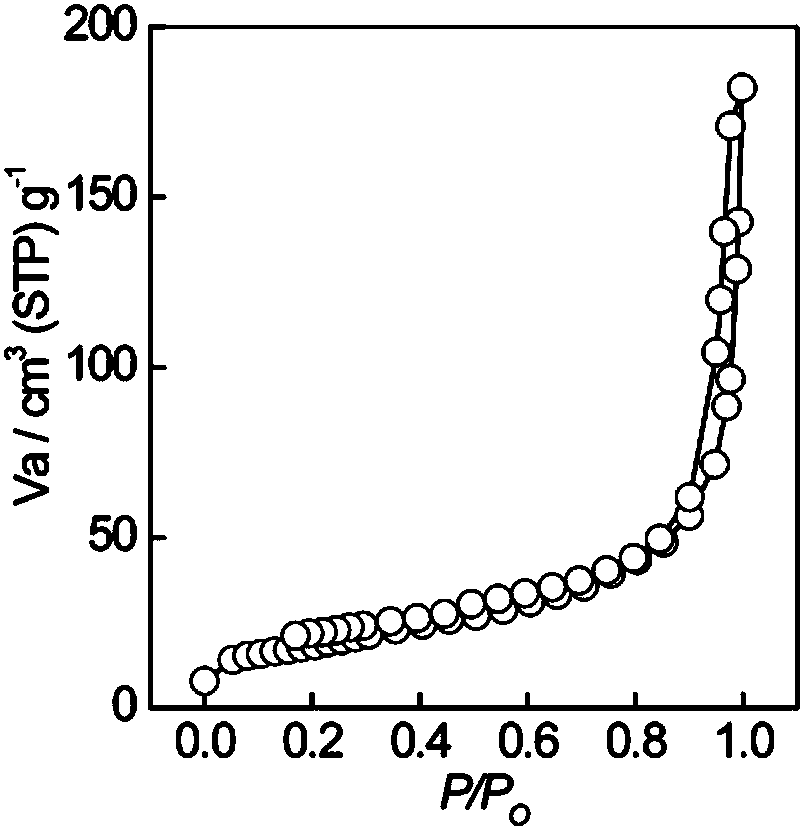

[0047] The specific surface area of the three-dimensional porous graphene-silicon composite electrode material is 346m 2 / g, the pore volume is 0.41cm 3 / g, the block density is 0.93g / cm 3 .

Embodiment 3

[0049] The difference with embodiment 1 is:

[0050] The amount of graphene oxide dispersion was adjusted to 39.3mL, Na 2 S 2 o 3 ·5H 2 The amount of O was adjusted to 0.75g, the amount of hydrochloric acid was adjusted to 6.5mL, the amount of absolute ethanol was adjusted to 39.3ml, and the amount of nano-silicon was adjusted to 78.6mg. The rest are the same as in Example 1, and will not be repeated here.

[0051] The specific surface area of the three-dimensional porous graphene-silicon composite electrode material is 384m 2 / g, the pore volume is 0.34cm 3 / g, the bulk density is 0.98g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com