A kind of preparation method of graphene-based dense composite material

A composite material and graphene-based technology, applied in the field of energy storage, can solve the problems of limited volume specific capacity, low volume energy density of energy storage devices, and reduced material density, so as to promote effective lapping, shorten gelation time, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

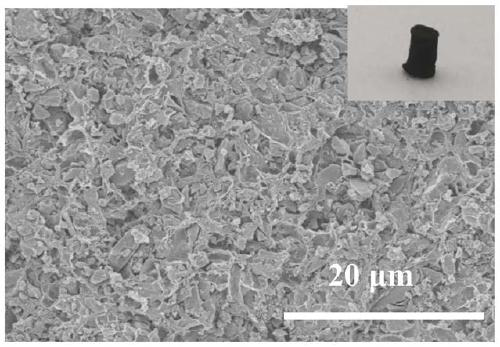

[0035] The present embodiment provides a kind of preparation method of graphene-based dense composite material, comprises the following steps at least:

[0036] In the first step, 38.5mL of 2mg / mL graphene oxide dispersion (solvent is water) is placed in a 100mL beaker, and 38.5mL of 2mg / mL activated carbon dispersion (solvent is methanol) is added to the beaker, fully stirred (30min) obtain the first mixed dispersion liquid;

[0037] In the second step, adding the reducing component ethylenediamine to the first mixed dispersion liquid obtained in the first step, and fully stirring for 30 minutes to obtain the second mixed dispersion liquid;

[0038] In the third step, the second mixed dispersion obtained in the second step is added to a 100mL hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 150°C, and the duration of the hydrothermal reaction is 6h to obtain graphene / Activated carbon composite hydrogel;

[0039] The fo...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of graphene-based dense composite material, comprises the following steps at least:

[0046] In the first step, 38.5mL of 3mg / mL modified graphene dispersion (solvent is water) is placed in a 100mL beaker, and 38.5mL of 4mg / mL mesoporous carbon dispersion (solvent is ethanol) is added to the beaker, Thoroughly stir (60min) to obtain the first mixed dispersion liquid;

[0047] In the second step, add reducing component urea to the first mixed dispersion liquid obtained in the first step, and fully stir for 60 minutes to obtain the second mixed dispersion liquid;

[0048] In the third step, the second mixed dispersion obtained in the second step is added to a 100mL hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 170°C, and the duration of the hydrothermal reaction is 10h to obtain graphene / Mesoporous carbon composite hydrogels;

[0049] The fourth step i...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of graphene-based dense composite material, comprises the following steps at least:

[0053] The first step, 38.5mL 5mg / mL porous graphene dispersion (solvent is water) is placed in 100mL beaker, in this beaker, add 38.5mL 3mg / mL carbon fiber dispersion (solvent is acetone), fully stir ( 40min) to obtain the first mixed dispersion;

[0054] In the second step, add the reducing component hydrazine hydrate to the first mixed dispersion liquid obtained in the first step, and fully stir for 50 minutes to obtain the second mixed dispersion liquid;

[0055] In the third step, the second mixed dispersion obtained in the second step is added to a 100mL hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 140°C, and the duration of the hydrothermal reaction is 30h to obtain graphene / Carbon fiber composite hydrogel;

[0056] The fourth step is to fully soak the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com