A kind of preparation method of the lithium ion battery silicon negative pole of a kind of multilevel structure

A lithium-ion battery, silicon negative electrode technology, applied in battery electrodes, structural parts, secondary batteries, etc., can solve the problems of silicon active particle fragmentation, pulverization, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

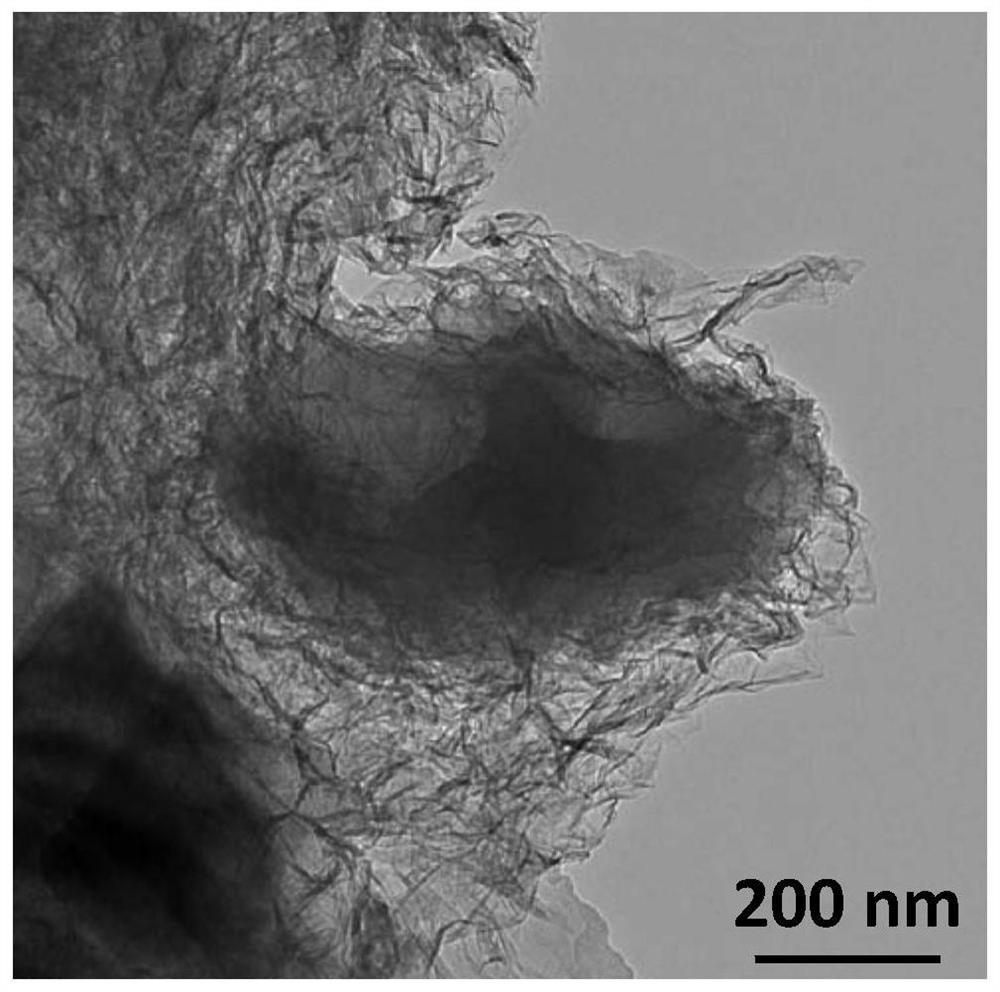

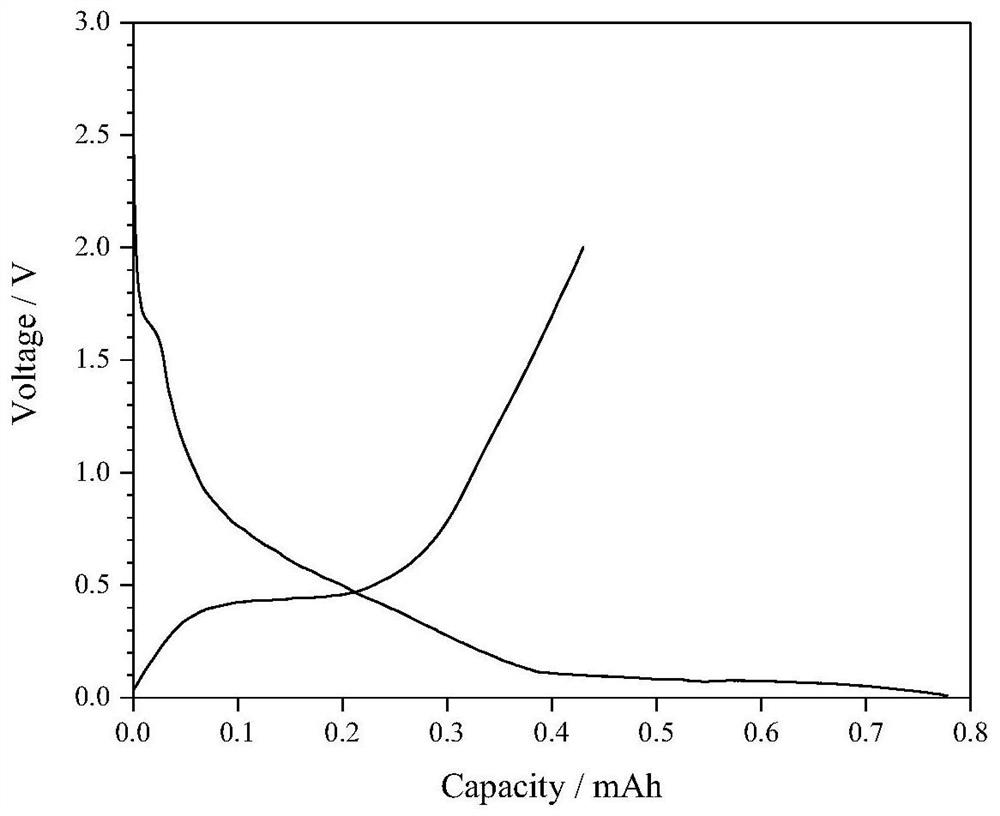

Image

Examples

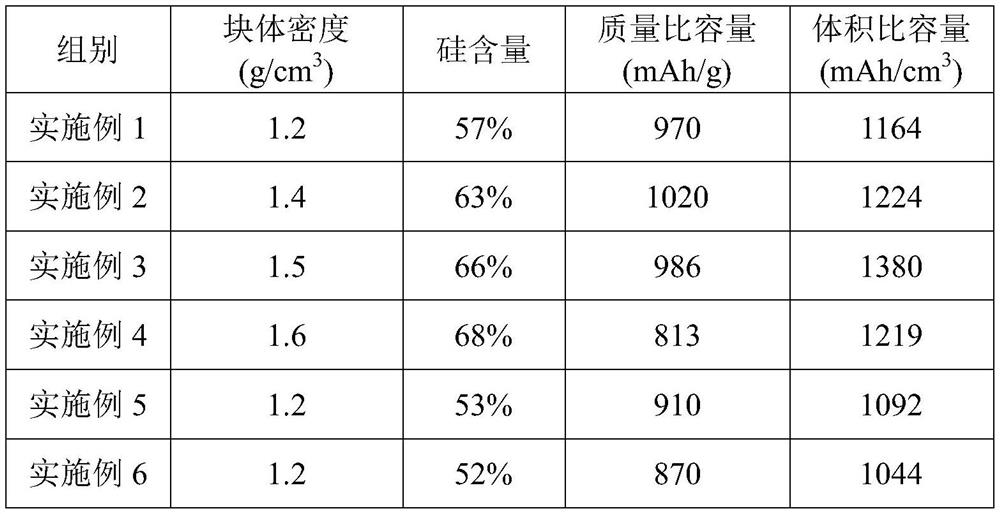

Embodiment 1

[0033] This embodiment provides a multi-level structure of high volume performance lithium ion battery micron silicon anode and a preparation method thereof, which at least include the following steps:

[0034] In the first step, 200 mg of micron silicon powder and 800 mg of sublimed sulfur are ground and mixed uniformly, and then placed in a tube furnace for heat treatment at 155°C under an inert atmosphere for 6 hours;

[0035] In the second step, add the powder obtained in the first step together with 500 mg of dopamine and 40 g of ferric nitrate nonahydrate to 250 mL of Tris-HCl buffer solution with pH=8.5, and react at room temperature for 24 hours with sufficient stirring;

[0036] In the third step, the product to be processed obtained in the second step is centrifuged to obtain a solid, and 90 mL of graphene oxide dispersion with a concentration of 2 mg / mL is added, and the mixture is stirred alternately and sonicated for 30 minutes to fully mix. Afterwards, the mixed dispers...

Embodiment 2

[0042] The difference from Example 1 is:

[0043] The amount of micron silicon is adjusted to 300 mg, and the amount of sublimed sulfur is adjusted to 700 mg, and the rest is the same as in Example 1, which will not be repeated here. The bulk density of the graphene / silicon composite material is 1.4g / cm 3 , The silicon content is 63%.

Embodiment 3

[0045] The difference from Example 1 is:

[0046] The amount of micron silicon is adjusted to 400 mg, and the amount of sublimed sulfur is adjusted to 600 mg, and the rest is the same as in Example 1, which will not be repeated here. The bulk density of the graphene / silicon composite material is 1.5g / cm 3 , The silicon content is 66%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com