Solar heat reflection type heat insulation coating structure and preparation method thereof

A technology of heat insulation and solar heat, applied in the direction of reflection/signal paint, coating, filling slurry, etc., can solve the problem of high air permeability and weather resistance of anti-cracking mortar, poor adhesion of wall base, heat preservation Unsatisfactory board application and other problems, to achieve excellent heat reflection cooling and heat insulation effect, save refrigeration costs, and good scraping construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

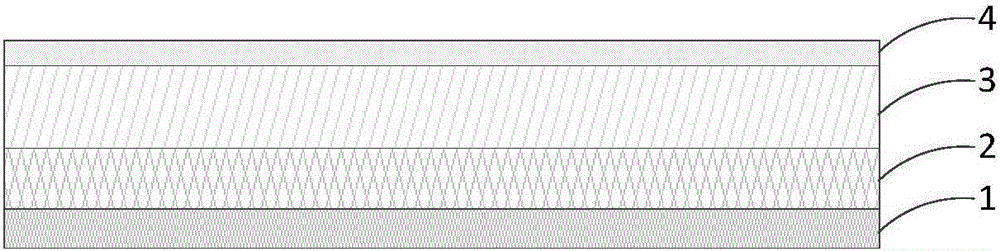

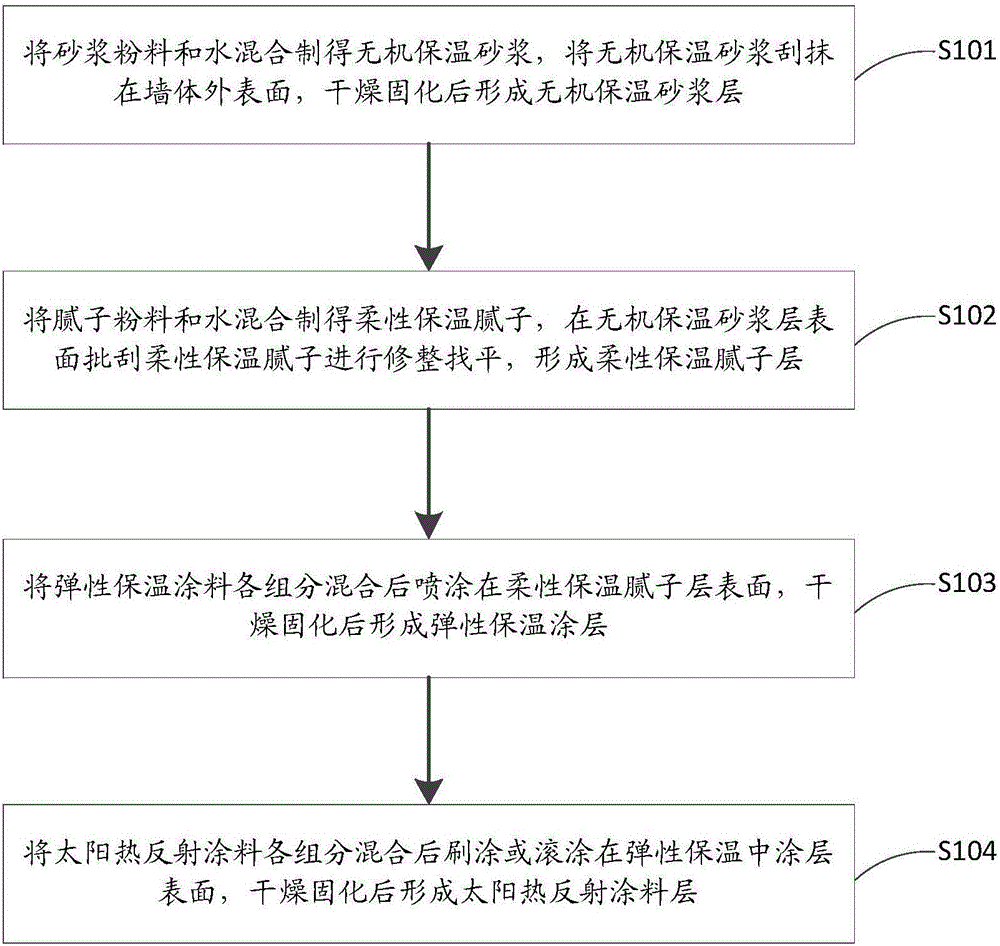

[0037] Such as figure 2 Shown, the preparation method of solar heat reflection thermal insulation coating structure among the present invention, comprises the following steps:

[0038] S101. Mix the mortar powder and water to prepare an inorganic thermal insulation mortar, scrape the inorganic thermal insulation mortar on the outer surface of the wall, dry and solidify to form an inorganic thermal insulation mortar layer 1;

[0039] S102. Mix the putty powder and water to prepare a flexible thermal insulation putty, scrape the flexible thermal insulation putty on the surface of the inorganic thermal insulation mortar layer 1 for trimming and leveling, and form a flexible thermal insulation putty layer 2;

[0040] S103. Mix the components of the elastic thermal insulation coating and spray it on the surface of the flexible thermal insulation putty layer 2, and form the elastic thermal insulation coating 3 after drying and curing;

[0041] S104. Brush or roll coat the components...

Embodiment 1

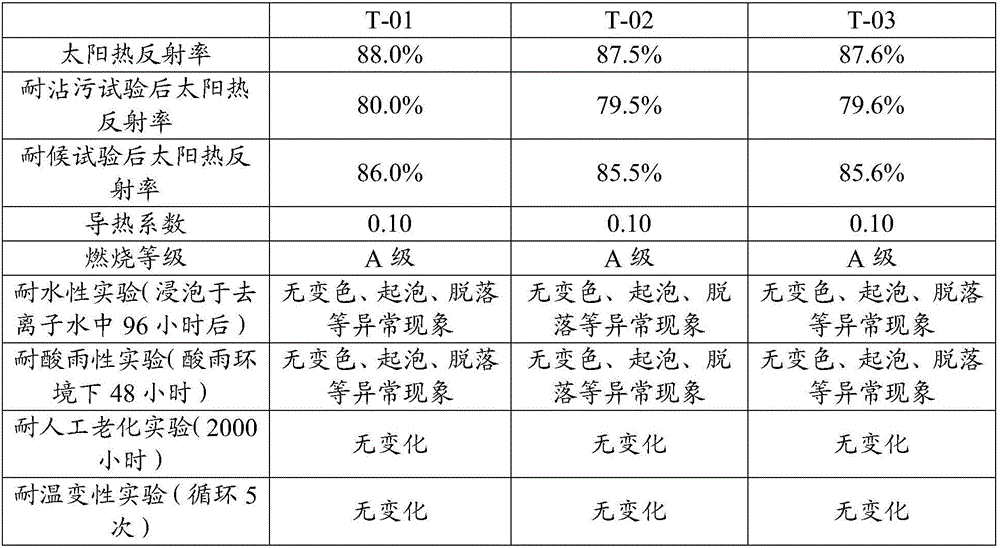

[0048] Preparation of solar heat reflective thermal insulation coating structure T-01

[0049] 1.1. Material preparation

[0050] 1.11. Preparation of inorganic thermal insulation mortar: weigh each component of the mortar powder according to the following weight percentages: cement 55%, floating beads 5%, vitrified microspheres 30%, wollastonite powder 6%, redispersible latex powder 3 %, 0.3% polypropylene fiber, 0.3% hydroxypropyl methyl cellulose ether, and 0.4% wood fiber. Stir and mix the above components with a disperser to form a mortar powder. Before construction, mix water and mortar powder according to The weight ratio of 8:10 is stirred evenly and stored for later use.

[0051] Among them, the cement is 42.5 grade ordinary Portland cement from Chongqing Conch Cement Co., Ltd., the floating beads are from Jiangsu Zhenjiang Blue Ribbon Thermal Insulation Material Factory, the vitrified microbeads are from Henan Xinyang Zhengda New Material Co., Ltd., and the wollasto...

Embodiment 2

[0064] Preparation of solar heat reflective thermal insulation coating structure T-02

[0065] 2.1. Material preparation

[0066] 2.11. Preparation of inorganic thermal insulation mortar: weigh each component of the mortar powder according to the following weight percentages: cement 50%, sepiolite 6%, vitrified microbeads 30%, wollastonite powder 8%, redispersible latex powder 5%, polypropylene fiber 0.2%, hydroxypropyl methyl cellulose ether 0.3%, wood fiber 0.5%, use a disperser to mix the above components evenly to form a mortar powder, mix water and mortar powder before construction Stir and mix evenly according to the weight ratio of 7:10, save it for later use.

[0067] Among them, the cement is 42.5 grade ordinary Portland cement from Chongqing Conch Cement Co., Ltd., the vitrified microbeads come from Henan Xinyang Zhengda New Material Co., Ltd., the wollastonite powder comes from Guangde Zhengyuan Wollastonite Powder Co., Ltd., and the redispersible latex The powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com