Method for manufacturing bio-dynamic agricultural compost and compost fermentation vat

A biodynamic and manufacturing method technology, applied in the field of agricultural resource utilization, can solve the problems of mechanical equipment blockage, poor ventilation, and less fermentation time, and achieve the effects of improving the automation level, facilitating effective fermentation, and shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

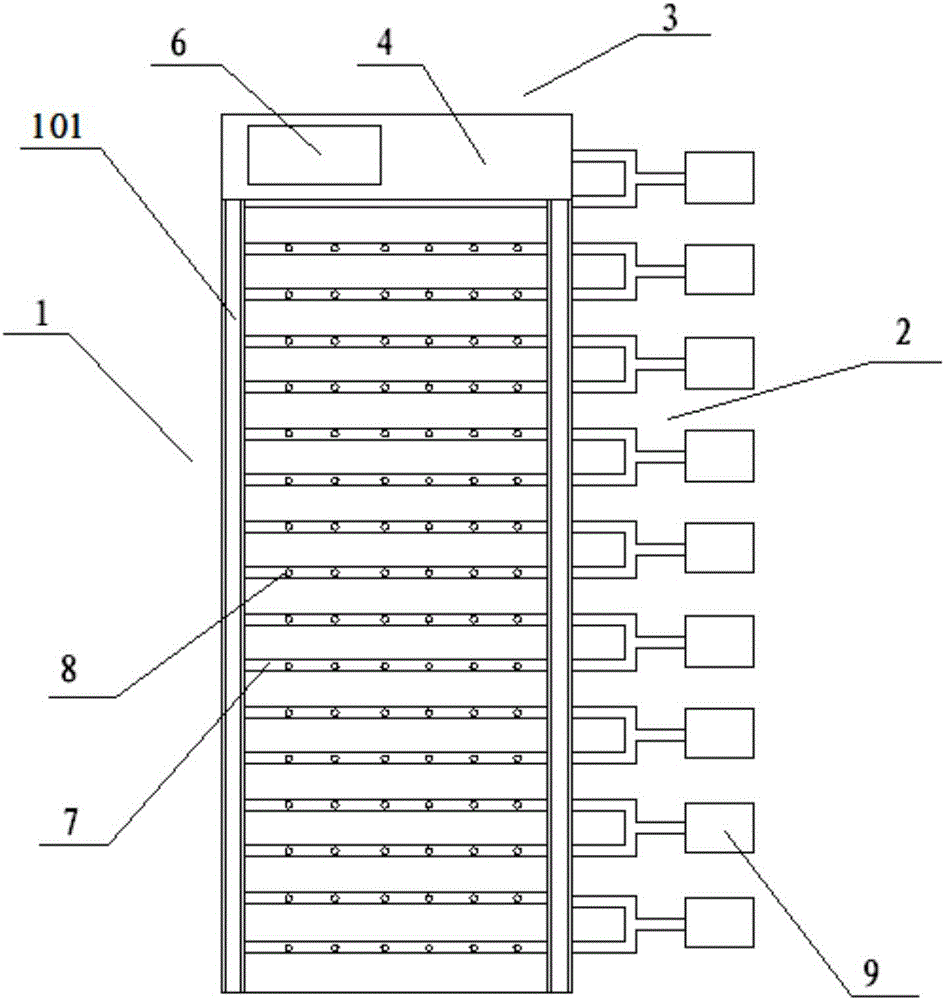

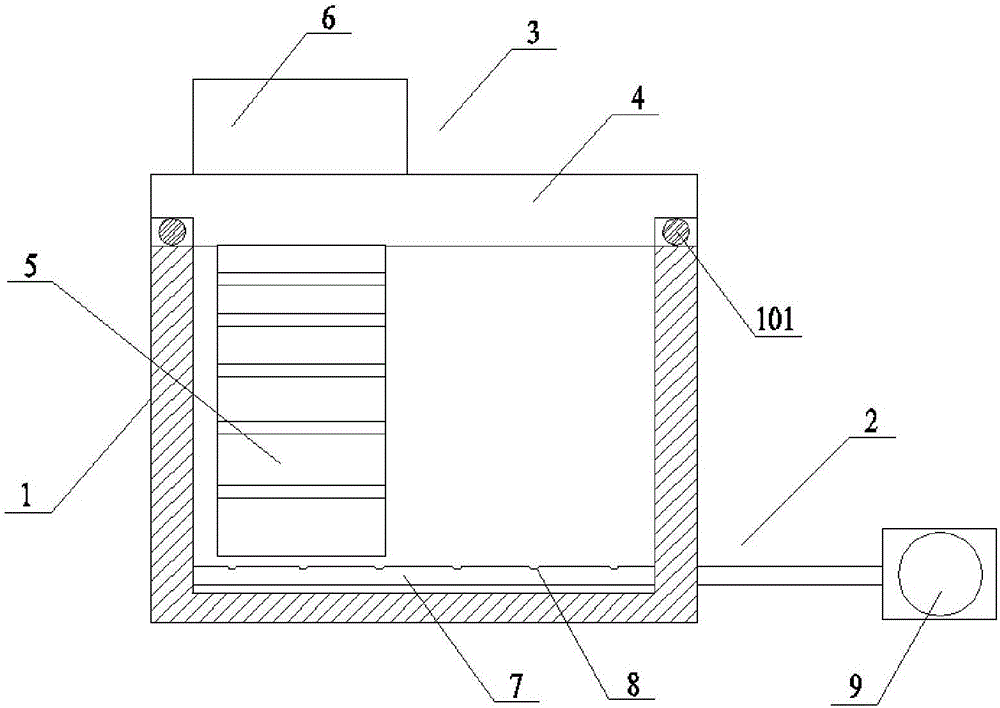

[0036] A biodynamic agricultural compost manufacturing method, comprising the following steps:

[0037] Adjust the carbon-nitrogen ratio of compost raw materials to 25:1-35:1 and put them into the pool; fermentation starts; at this time, the organic matter begins to be decomposed by microorganisms to release heat, and the temperature in the heap rises slowly.

[0038] Supplementing oxygen at the bottom of the compost raw material through an oxygen supply device;

[0039] After the fermentation starts, use a pusher to step and push the compost material to move forward along the pool body;

[0040] As the compost raw materials are progressively advanced, sequentially add compost-modulating elements, and supplement oxygen to the compost raw materials;

[0041] Every step, the turning machine turns over the compost raw materials mixed with the compost regulating factor.

[0042] As described in this embodiment, each turning process performed by the turning machine includes at le...

Embodiment 2

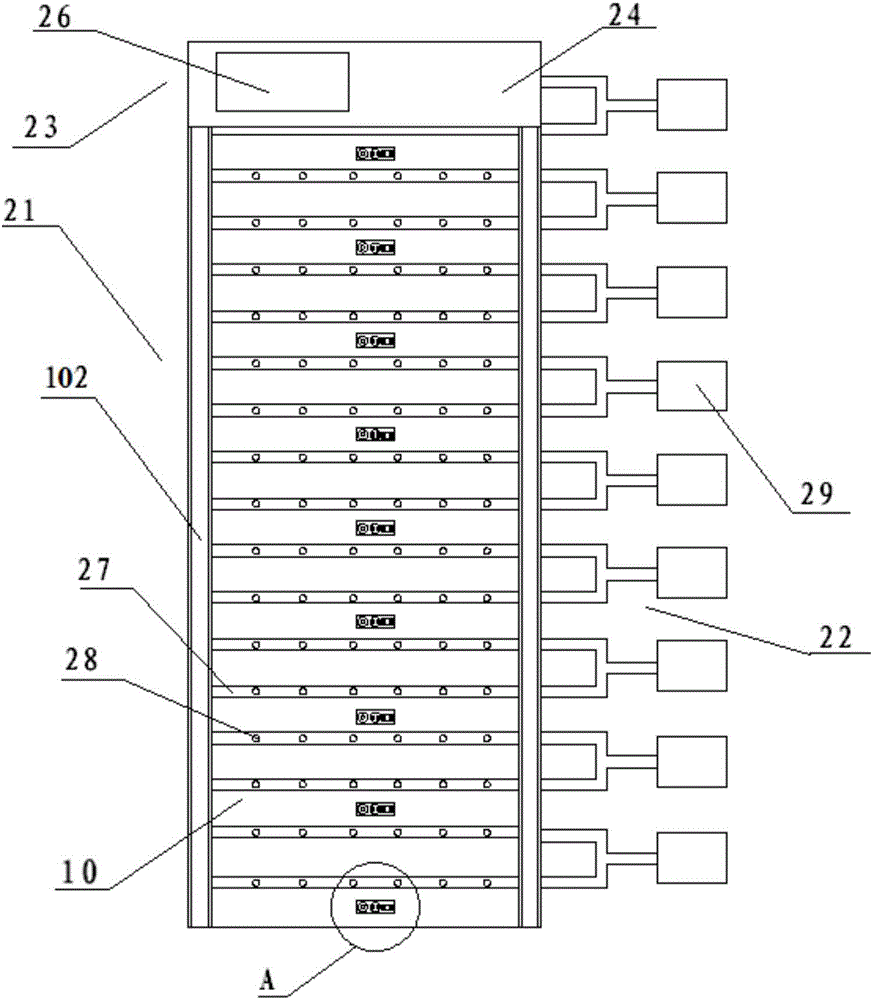

[0061] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0062] A biodynamic agricultural compost manufacturing method, comprising the following steps:

[0063] Adjust the carbon-nitrogen ratio of compost raw materials to 25:1-35:1 and put them into the pool; fermentation starts; at this time, the organic matter begins to be decomposed by microorganisms to release heat, and the temperature in the heap rises slowly.

[0064] Supplementing oxygen at the bottom of the compost raw material through an oxygen supply device;

[0065] After the fermentation starts, use a pusher to step and push the compost material to move forward along the pool body;

[0066] As the compost raw materials are progressively advanced, sequentially add compost-modulating elements, and supplement oxygen to the compost raw materials;

[0067] Every step, the turning machine t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com