A kind of dopo derivative flame retardant containing silicon and fluorine and preparation method thereof

A technology of derivatives and flame retardants, which is applied in the field of DOPO derivative flame retardants containing silicon and fluorine and its preparation, can solve the problems of unfavorable material performance and influence, and achieve excellent thermal stability, good chemical stability, Good surface migration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

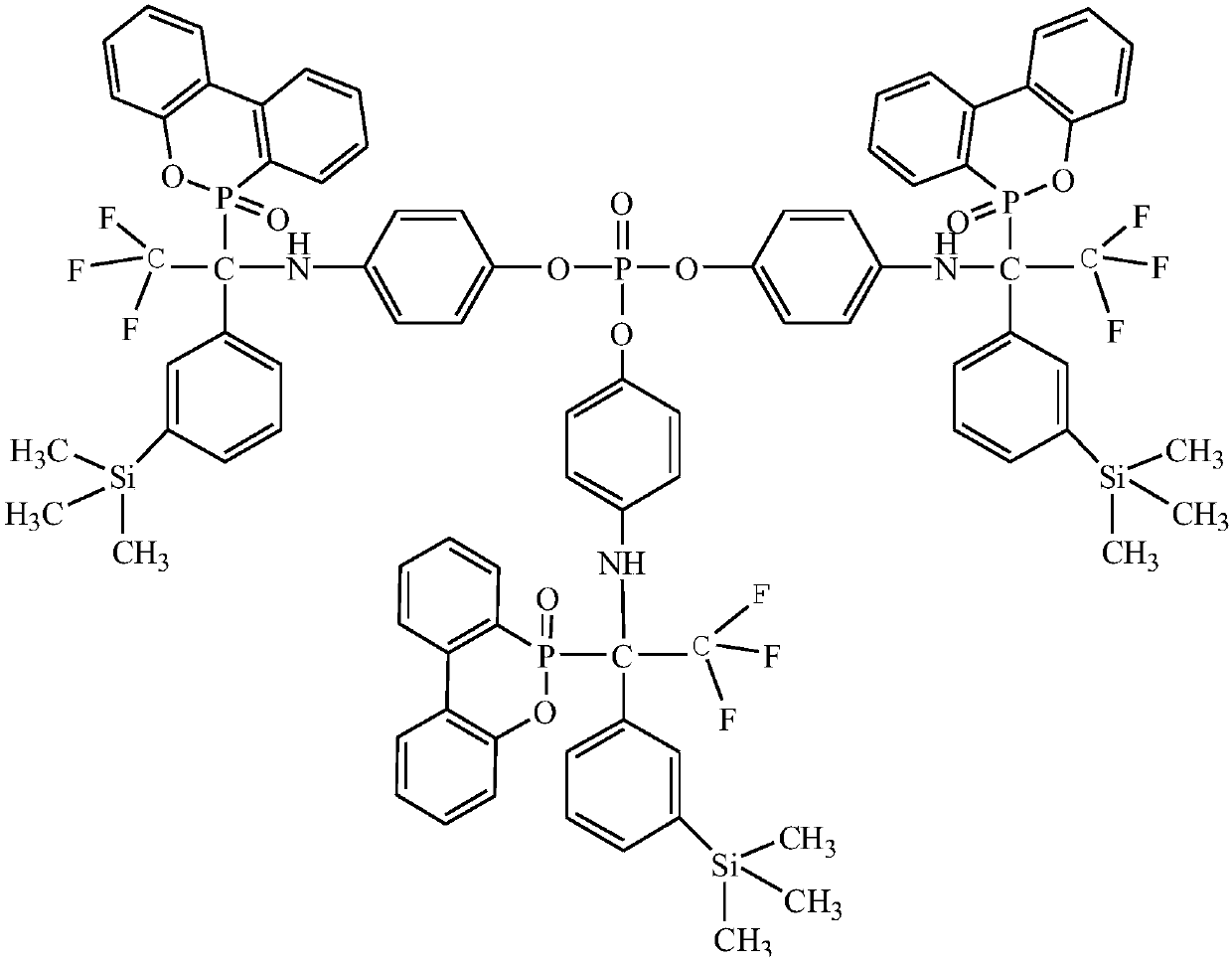

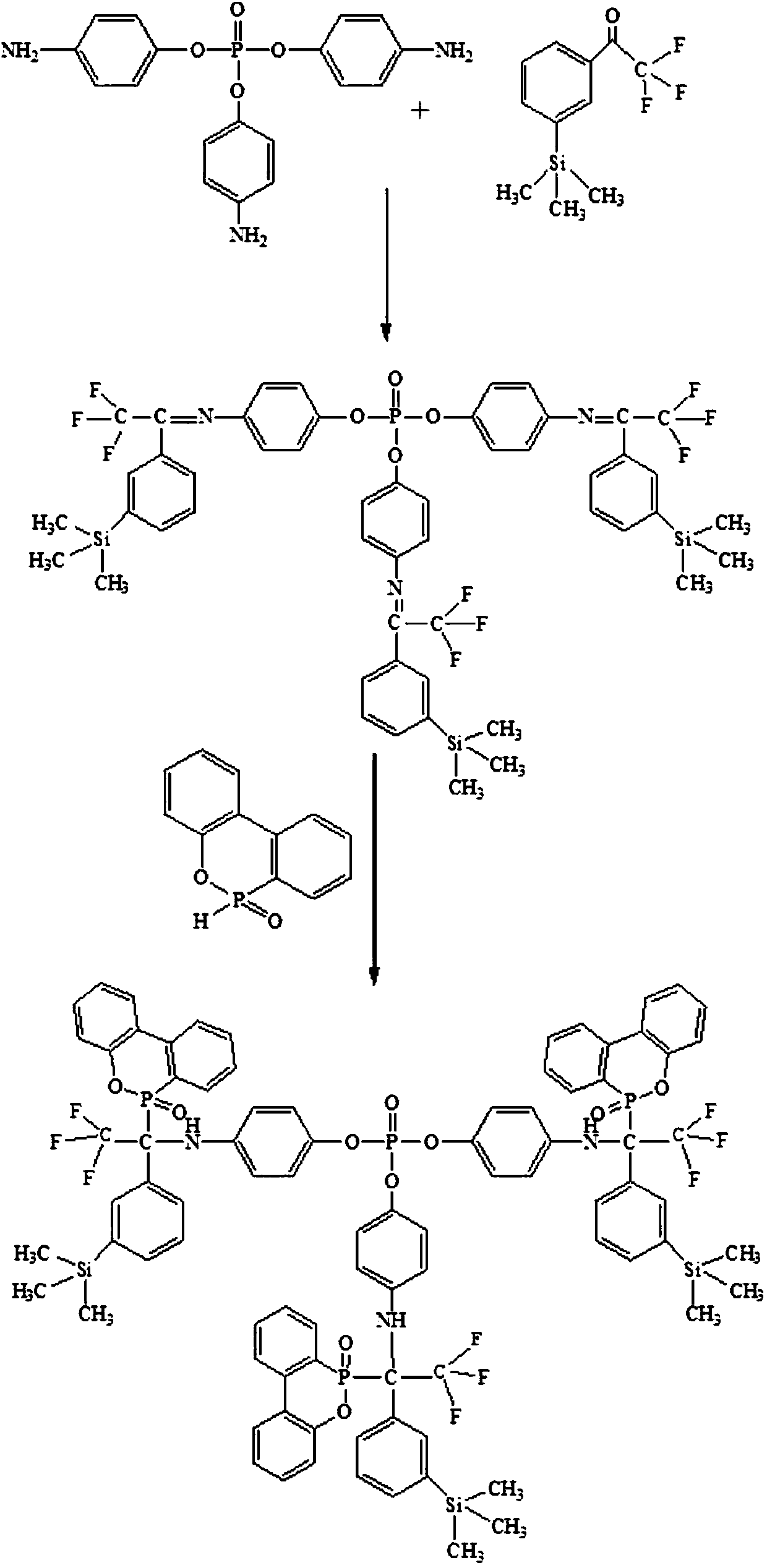

[0029] The synthesis steps of a nitrogen-phosphorus-containing silicone flame retardant are:

[0030] (1) Heat 11.1 g of tris(4-aminophenyl) phosphate and 22.2 g of Zirosilicone in 166.3 g of ethanol at 75° C. for 5 hours. After the reaction is completed, a reaction system containing intermediate product I is obtained;

[0031] (2) Add 19.5 g of DOPO to the reaction system containing intermediate product I obtained in step (1) and heat it at 75° C. for 5 hours. After the reaction, wash and dry to obtain a silicon and fluorine-containing DOPO derivative barrier. Burning agent, the yield is 86.4%.

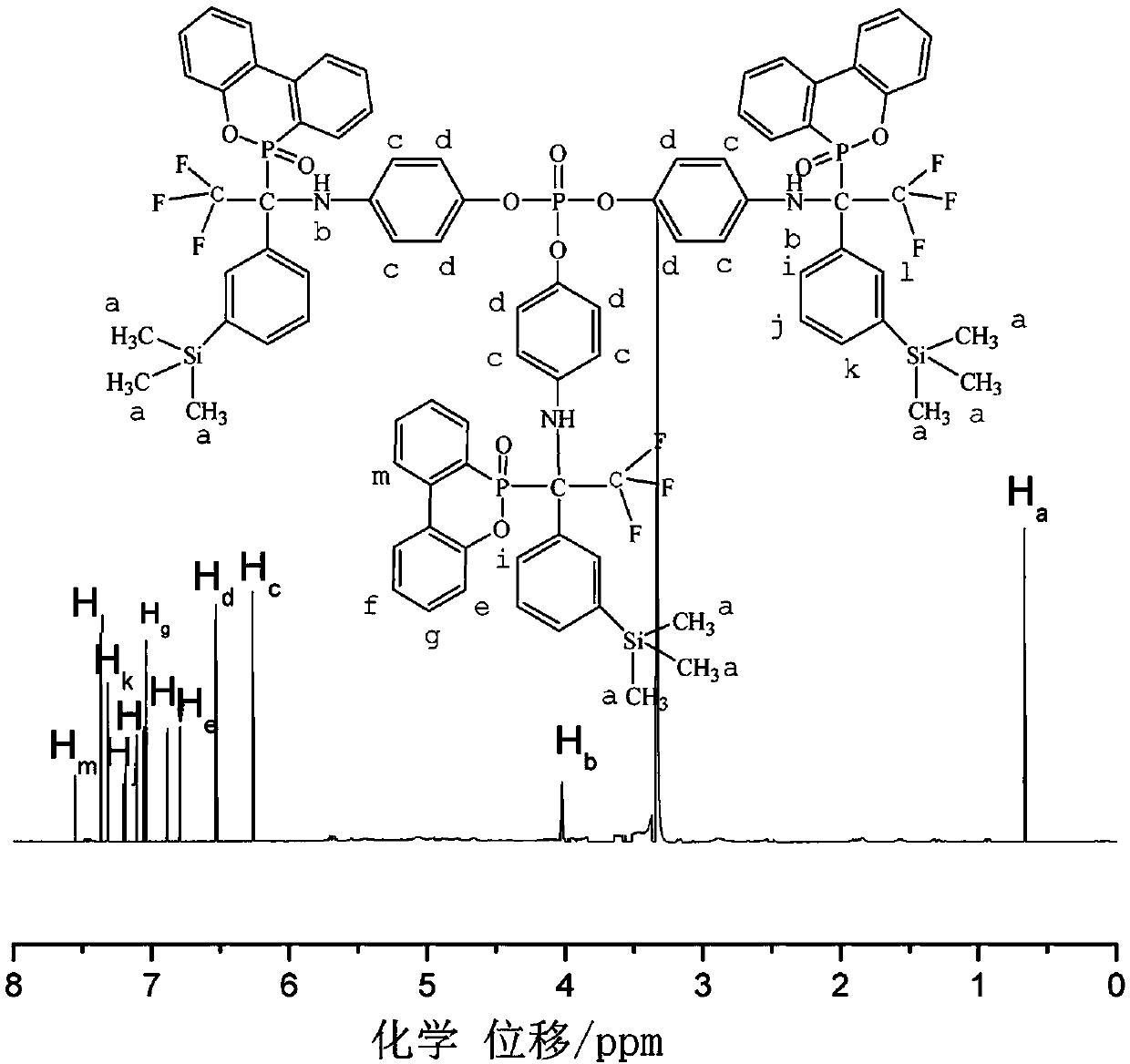

[0032] The infrared test results are as follows:

[0033] FTIR (KBr): N-H stretching vibration peak 3410cm -1 , C-H stretching vibration peak 3070cm -1 , C-N characteristic peak 1288cm -1 , C-F characteristic peak 1105cm -1 , C-Si characteristic peak 1255cm -1 , P-O-C characteristic peak 1032cm -1 , P-O-Ph characteristic peak 1231cm -1 , P-Ph characteristic peak 1595cm -1 , P=O characteristi...

Embodiment 2

[0037] The synthesis steps of a nitrogen-phosphorus-containing silicone flame retardant are:

[0038] (1) Heat 18.6g of tris(4-aminophenyl) phosphate and 37g of Zirosilicone in 388.8g of DMF at 75°C for 7h, after the reaction is over, a reaction system containing intermediate product I is obtained;

[0039] (2) Add 32.4g of DOPO to the reaction system containing intermediate product I obtained in step (1) and heat it at 75°C for 7 hours. After the reaction, wash and dry to obtain silicon and fluorine-containing DOPO derivatives. Burning agent, the yield is 86.2%.

[0040] The infrared test results are as follows:

[0041] FTIR (KBr): N-H stretching vibration peak 3410cm -1 , C-H stretching vibration peak 3075cm -1 , C-N characteristic peak 1287cm -1 , C-F characteristic peak 1105cm -1 , C-Si characteristic peak 1255cm -1 , P-O-C characteristic peak 1033cm -1 , P-O-Ph characteristic peak 1232cm -1 , P-Ph characteristic peak 1595cm -1 , P=O characteristic peak 1212cm -1 , The out-of-pla...

Embodiment 3

[0043] The synthesis steps of a nitrogen-phosphorus-containing silicone flame retardant are:

[0044] (1) Heat 37.1 g of tris(4-aminophenyl) phosphate and 73.9 g of zirosilicone in 999 g of DMSO at 75° C. for 10 hours. After the reaction is completed, a reaction system containing intermediate product I is obtained;

[0045] (2) 64.9g of DOPO was added to the reaction system containing intermediate product I obtained in step (1) and heated at 75°C for 9 hours. After the reaction, it was washed and dried to obtain silicon and fluorine-containing DOPO derivative barriers. Burning agent, the yield is 86.6%.

[0046] The infrared test results are as follows:

[0047] FTIR (KBr): N-H stretching vibration peak 3415cm -1 , C-H stretching vibration peak 3085cm -1 , C-N characteristic peak 1287cm -1 , C-F characteristic peak 1105cm -1 , C-Si characteristic peak 1254cm -1 , P-O-C characteristic peak 1033cm -1 , P-O-Ph characteristic peak 1232cm -1 , P-Ph characteristic peak 1595cm -1 , P=O chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com