High-shrinkage biaxially-oriented nylon 6 film with hot shrinkage reaching 8-10% and manufacture method thereof

A technology of biaxially stretched nylon and thermal shrinkage rate, applied in the field of nylon film, can solve problems such as the barrier property is not as good as that of nylon film, and it is difficult to achieve thermal shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

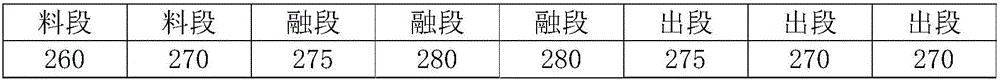

[0022] The high-shrinkage biaxially oriented nylon 6 film with a thermal shrinkage rate of 8-10% in this embodiment is prepared according to the following process.

[0023] Feeding:

[0024] Put the raw materials in the following weight ratios into the drying tank:

[0025] 80 parts of nylon 6,

[0026] Special nylon MXD6 20 parts,

[0027] Anti-blocking agent silicon dioxide 0.5 parts,

[0028] Among them: the viscosity of nylon 6 and special nylon are both 2.8-3.2.

[0029] Raw material drying:

[0030] Steam heating is used. After the temperature reaches 90 degrees, the vacuum pump is turned on for drying. After 30 minutes, the vacuum pump is stopped and filled with nitrogen. The moisture is sampled and tested. When the dryness reaches 1000-1100ppm, the drying ends, otherwise repeat the drying.

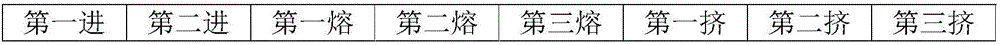

[0031] Melt extrusion:

[0032] The raw material enters the extruder after drying, the feeding port is protected by vacuum, the vacuum degree is stable at -80kpa, and the raw material enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com