Modified graphene phase change microcapsule and preparation method thereof

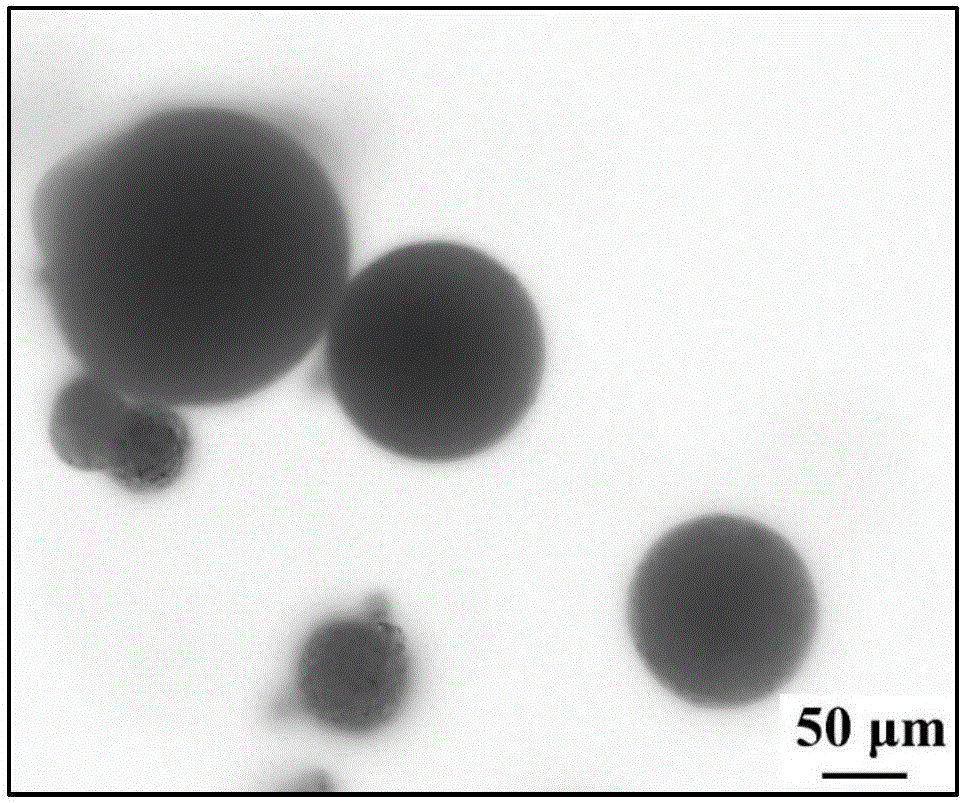

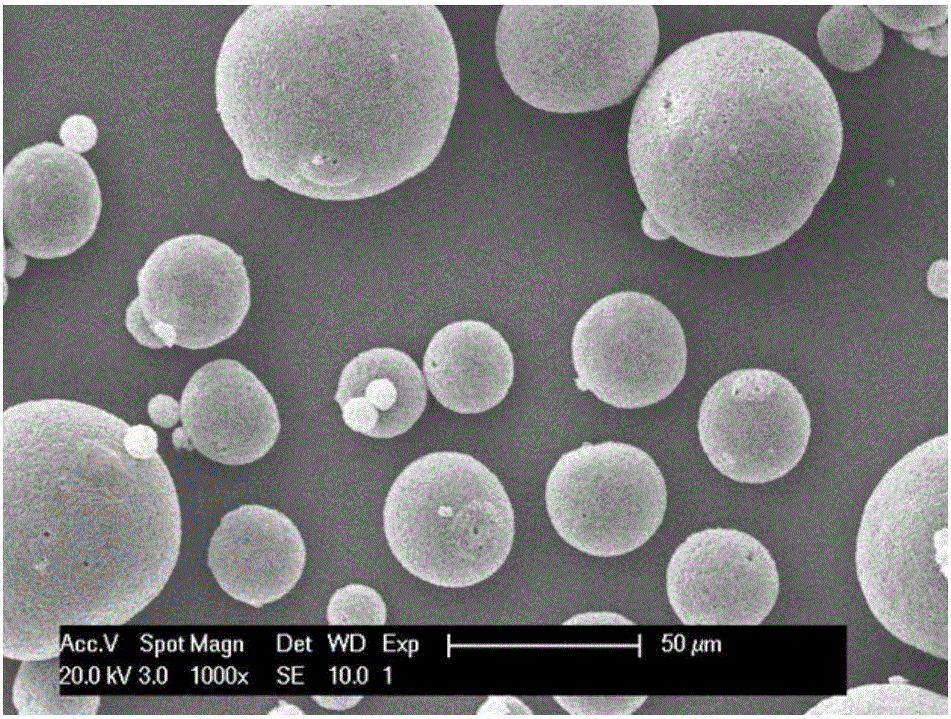

A phase change microcapsule, graphene technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of phase change enthalpy reduction, phase change material leakage, etc., and achieve high encapsulation rate and uniform particle size distribution. , the effect of avoiding leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, add 0.1g sodium dodecylsulfonate (SDBS) into 150ml deionized water, stir to obtain SDBS aqueous solution;

[0031] Step 2: Melt 10 g of sliced paraffin and add it to the aqueous solution in step 1. Under the condition of 55° C., 150 W ultrasonic wave for 2 hours to obtain sliced paraffin emulsion;

[0032] Step 3, disperse 0.01g of modified graphene into 150ml of deionized water, then add hydrochloric acid with a concentration of 0.1mol / L to adjust the pH of the solution to 1, and then 100W ultrasonic for 10min to obtain a modified graphene solution;

[0033] Step 4, the modified graphene solution obtained in step 3 is added to the sliced paraffin emulsion obtained in step 2, and 100W is ultrasonicated for 10 minutes, and the ultrasonic wave makes the wall material and the core material combine through the electrostatic force between charges to obtain a phase change wrapped in modified graphene microcapsule preparation;

[0034] Step 5, cooling the modifi...

Embodiment 2

[0036] Step 1, adding 0.5 g of succinate sulfonate to 150 ml of deionized water, and stirring to obtain an aqueous solution of succinate sulfonate;

[0037] Step 2: Melt 10 g of myristyl alcohol and add it to the aqueous solution in step 1. Under the condition of 58° C., 120 W ultrasound for 2.5 hours to obtain myristyl alcohol emulsion;

[0038] Step 3, disperse 0.1g of modified graphene into 150ml of deionized water, add hydrochloric acid with a concentration of 0.01mol / L to adjust the pH of the solution to 2, and then 120W ultrasonic for 30min to obtain a modified graphene solution;

[0039] In step 4, the modified graphene solution obtained in step 3 is added to the myristyl alcohol emulsion obtained in step 2, and 120W is ultrasonicated for 30 minutes, and the ultrasonic wave makes the wall material and the core material combine through the electrostatic force between the charges to obtain the phase wrapped in modified graphene. Variable microcapsule preparation;

[0040...

Embodiment 3

[0042] Step 1, add 0.8g fatty alcohol sulfate monoethanolamine salt into 150ml deionized water, and stir to obtain fatty alcohol sulfate monoethanolamine salt solution;

[0043] Step 2: Melt 10 g of cetyl alcohol and add it to the aqueous solution in step 1. Under the condition of 58 ° C, 130 W ultrasound for 2.5 hours to obtain cetyl alcohol emulsion;

[0044] Step 3, disperse 0.2 g of modified graphene into 150 ml of deionized water, add a hydrochloric acid solution with a concentration of 0.001 mol / L to a pH of 3, and then 130 W ultrasonic for 40 min to obtain a modified graphene solution;

[0045] Step 4, the modified graphene solution obtained in step 3 is added to the cetyl alcohol emulsion obtained in step 2, and 130W is ultrasonicated for 40 minutes, and the ultrasonic wave makes the wall material and the core material combine through the electrostatic force between charges to obtain the phase wrapped by modified graphene. Variable microcapsule preparation;

[0046] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com