Patents

Literature

40results about How to "Solve the problem of low thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

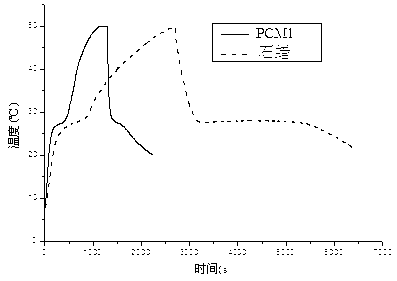

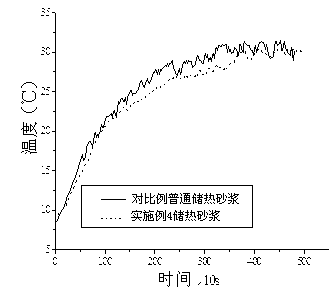

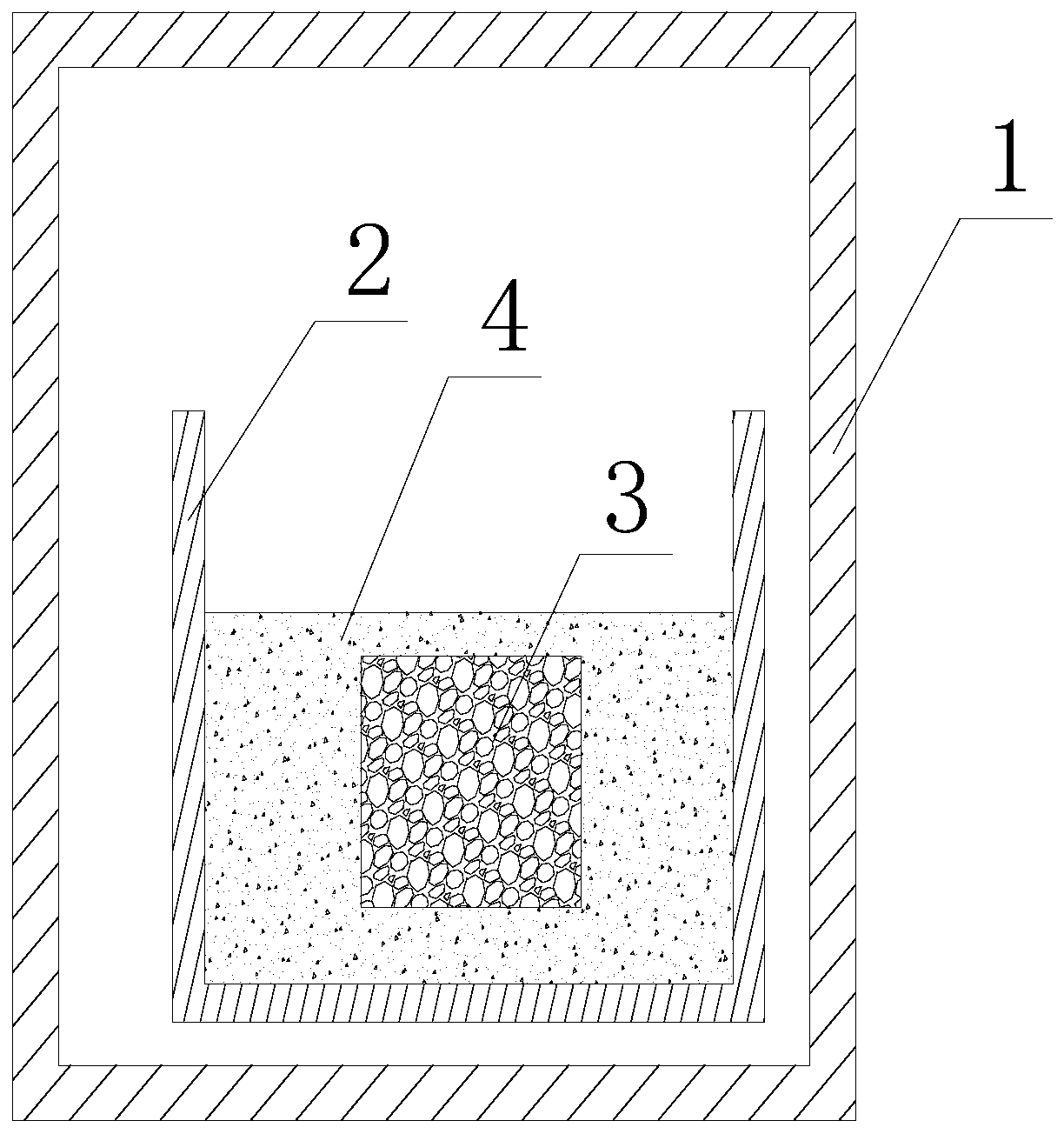

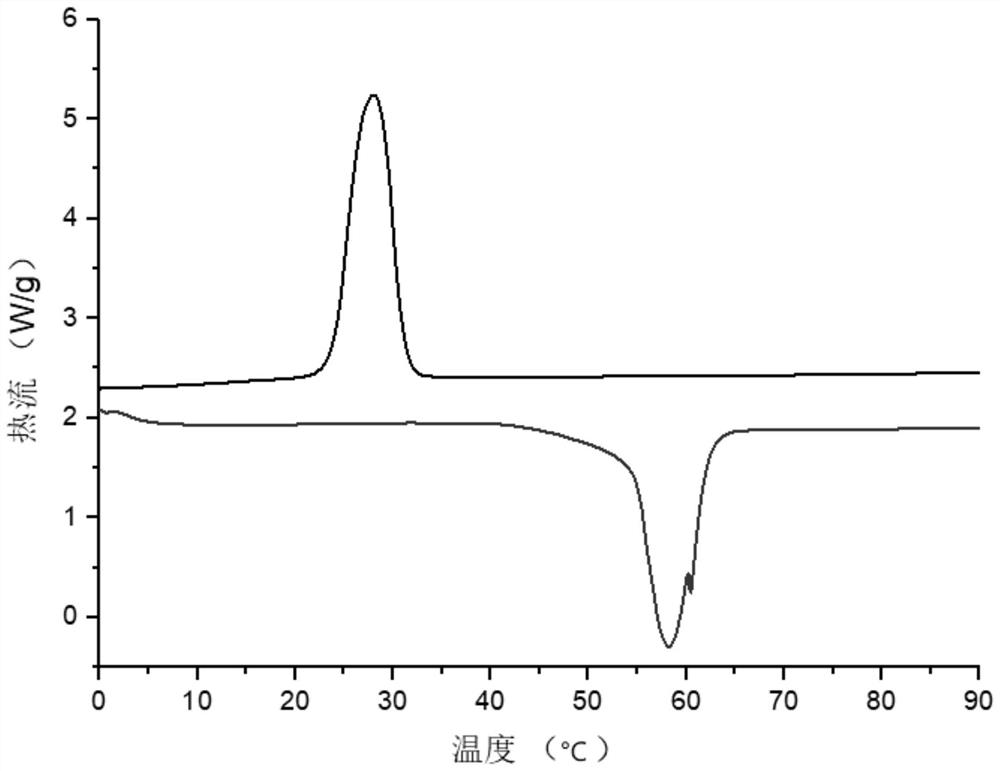

Composite shape-stabilized phase change material, preparation method and heat storage mortar prepared by using phase change material

InactiveCN103059817AIncrease heat storage rateSolve the problem of low thermal conductivityHeat-exchange elementsFiberHigh rate

The present invention relates to a phase change material and a heat storage mortar prepared by using the phase change material. The phase change material comprises, by weight: one part of an organic layered material, 1-4 parts of a heat conduction enhancer, and 10-20 parts of an organic phase change material. The phase change material has excellent heat storage effect and flame retardant properties, and has good compatibility with a base material. The heat storage mortar prepared by using the phase change material includes, by weight: one part of cement, 1.5-2.5 parts of a fine aggregate, 0.1-0.25 parts of a lightweight aggregate, 0.1-0.3 parts of the composite shape-stabilized phase change material, 0.005-0.02 parts of a binder, 0.001-0.004 parts of a water-retaining agent, 0.001-0.0025 parts of fiber, and 0.75 to 0.9 parts of water. The mortar has a high rate of heat storage, can improve the building thermal comfort, and reduce building energy consumption.

Owner:SOUTHEAST UNIV

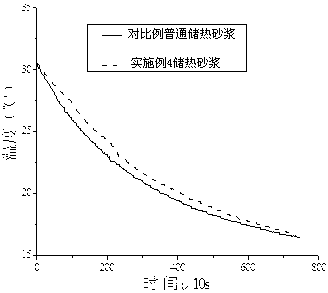

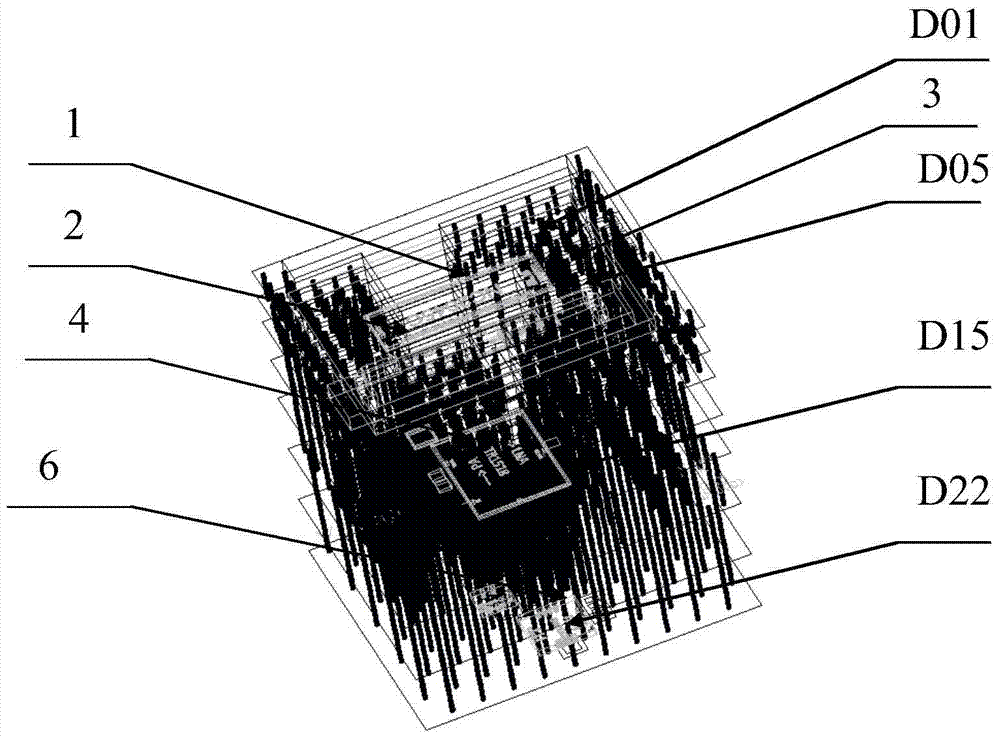

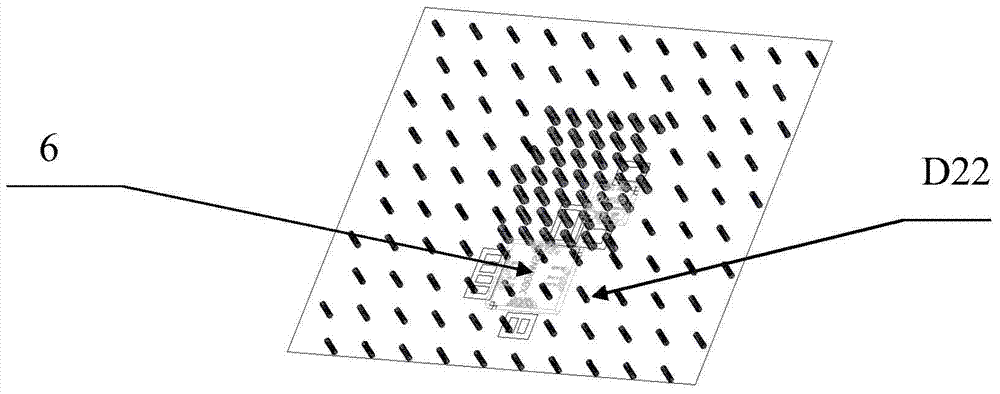

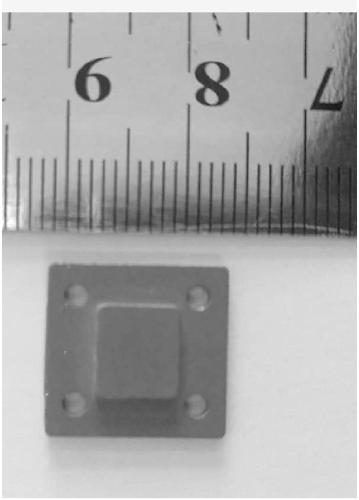

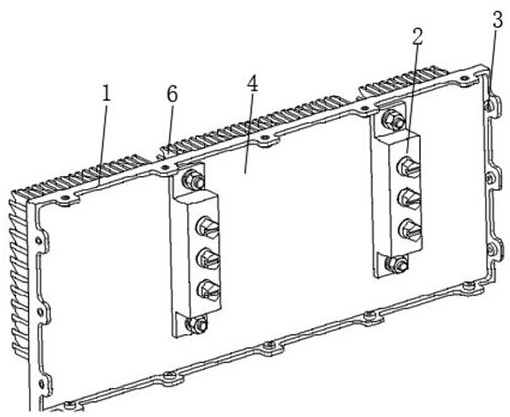

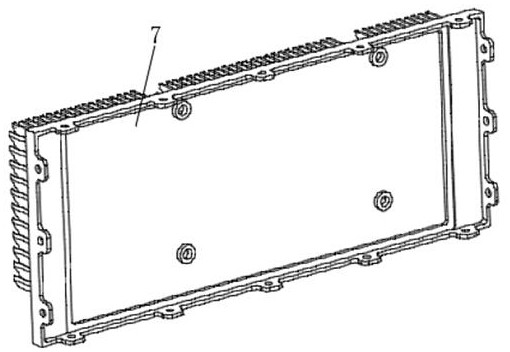

3D assembling method for integrally integrating chips of T/R assembly

InactiveCN104332413AHighly integratedLow costSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityThree-dimensional space

The invention provides a 3D assembling method for integrally integrating chips of T / R assembly, and aims to provide a T / R assembly which has advantages of reliable performance, higher density, more functions, high signal transmission speed, better performance and relatively lower cost. The 3D assembling method is realized through a solution which comprises the steps of performing z-direction expansion on a planar circuit with printed circuit patterns to a green ceramic chip laminate of a three-dimensional circuit through interlayer vertical interconnection; vertically packaging an active device in a rectangular chamber (7) of the green ceramic chip laminate (5), placing a power supply modulator on the back surface of the bottom of the green ceramic chip laminate, and inputting an outer signal from a low-frequency interface at the back surface of the green ceramic chip laminate to a pad of the green ceramic chip laminate (5); performing radio frequency connection among chips through a metal wire bonding vertical interconnection structure among the green ceramic chip laminates, accurately aligning and laminating the green ceramic laminates in a Z direction, and then sintering at a temperature of 900 DEG C, thereby preparing a three-dimensional circuit low-temperature co-sintered ceramic LTCC substrate which is used for high-density circuits with no three-dimensional space interference and is internally provided with a passive element and can be equipped with bare chips or package chips on the surface.

Owner:10TH RES INST OF CETC

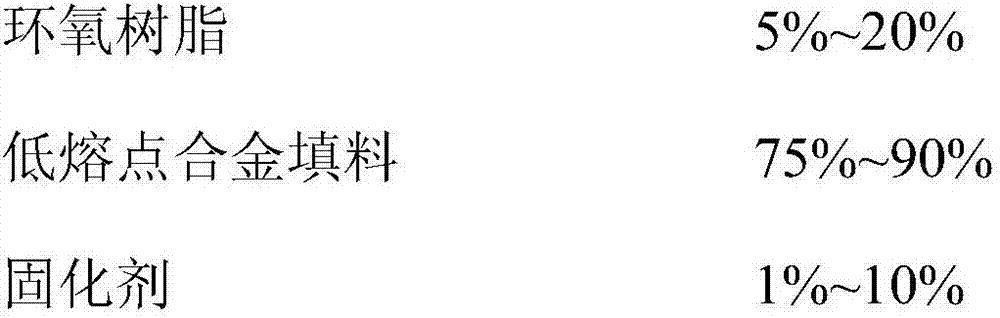

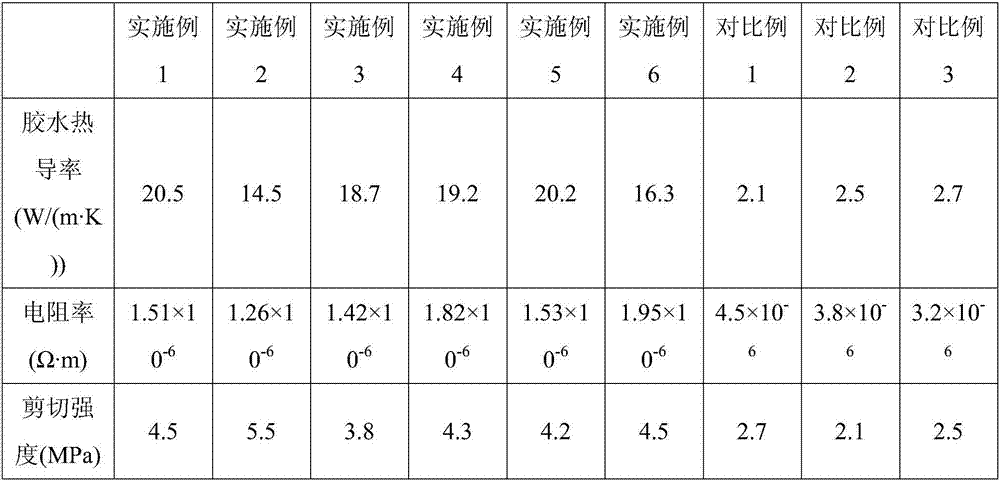

Thermally-conductive and electrically-conductive adhesive and preparation method and application thereof

PendingCN106883805AStrong welding abilityGood thermal and electrical conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal conductivityFilm-forming agent

The invention relates to a thermally-conductive and electrically-conductive adhesive and a preparation method and application thereof. The thermally-conductive and electrically-conductive adhesive comprises the following components in percentage by mass: 5-20% of epoxy resin, 75-90% of a low-melting point alloy filler, 1-10% of a curing agent, 0.1-3% of an accelerant and 0.1-10% of a diluent, and can further comprise a film-forming agent and a thixotropic agent. The preparation method comprises the following steps: mixing the components, and performing vacuum mixing on an obtained mixture for 3-5min to obtain a uniform pasty material, namely the thermally-conductive and electrically-conductive adhesive. The thermally-conductive and electrically-conductive adhesive provided by the invention can achieve good metallurgical interconnection after being cured at low temperature, so that the thermally-conductive and electrically-conductive adhesive not only has good welding capability, but also has good thermal conductivity and electrical conductivity.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

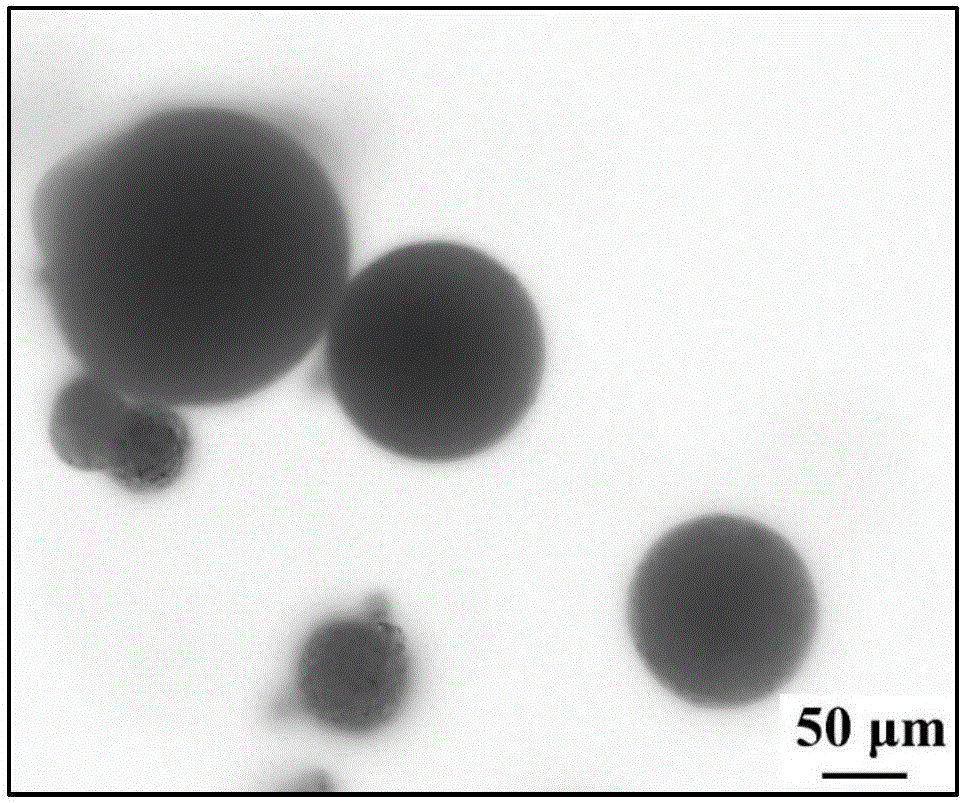

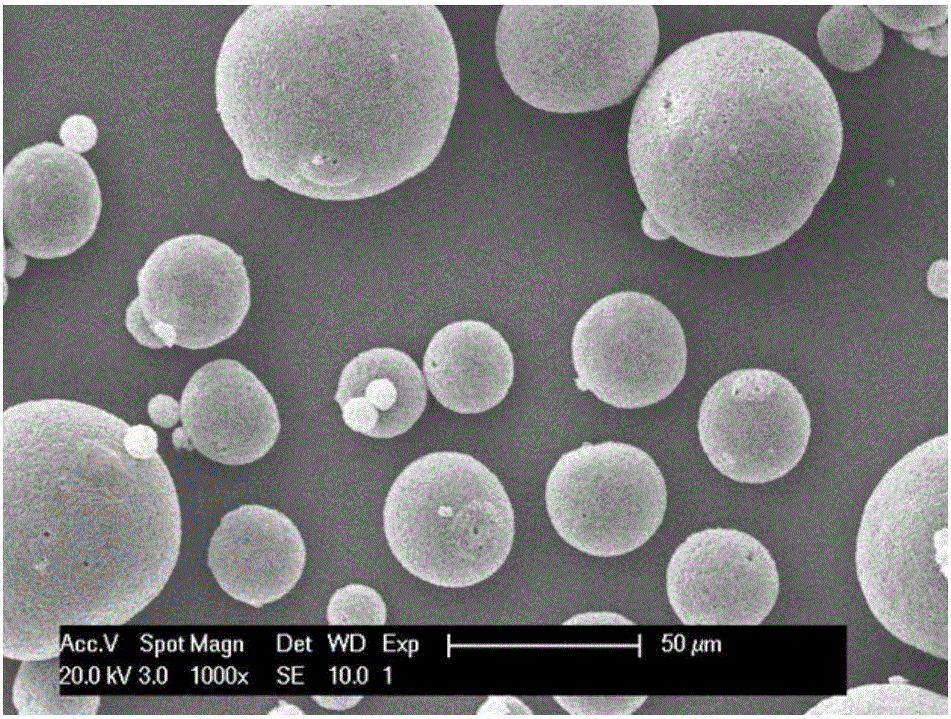

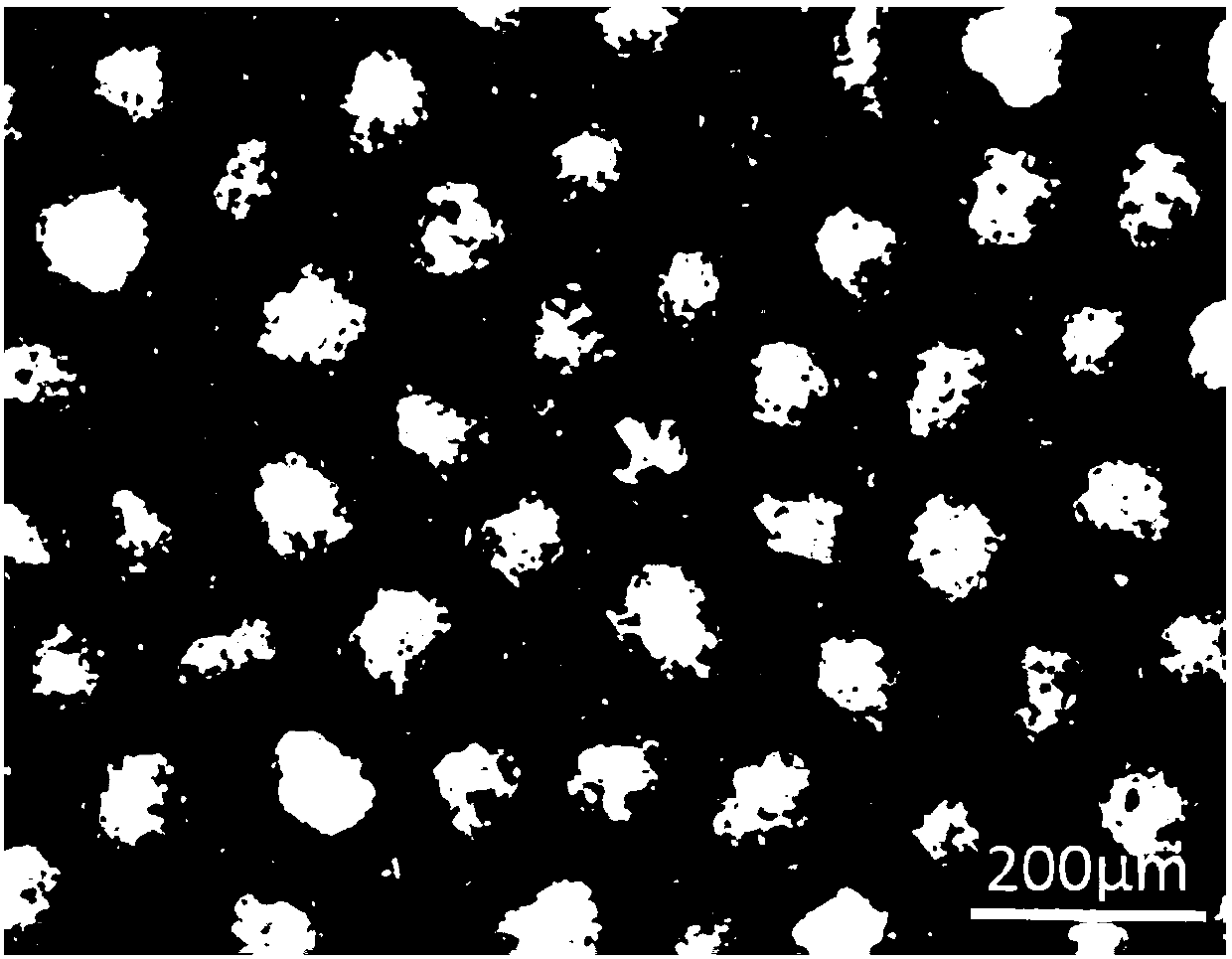

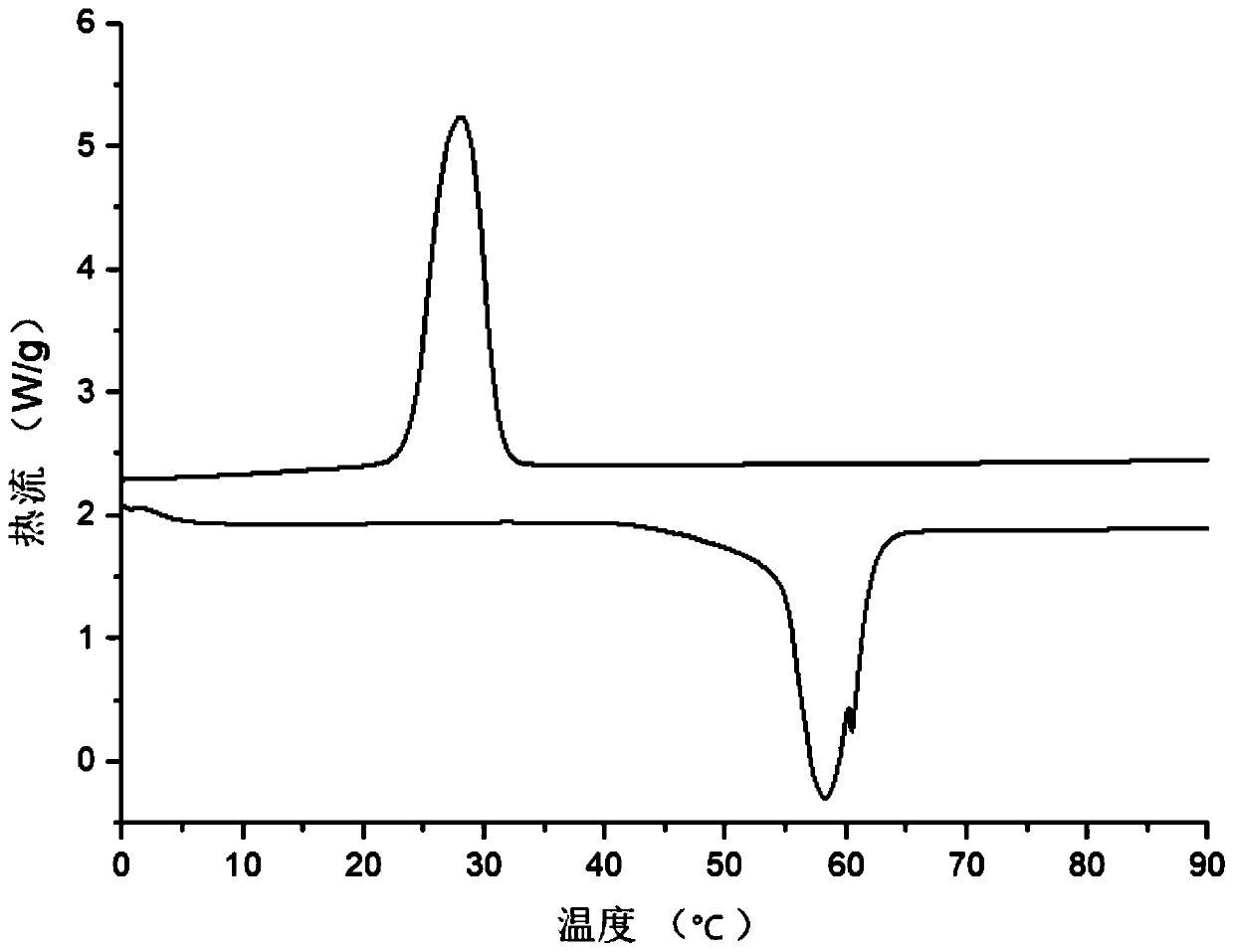

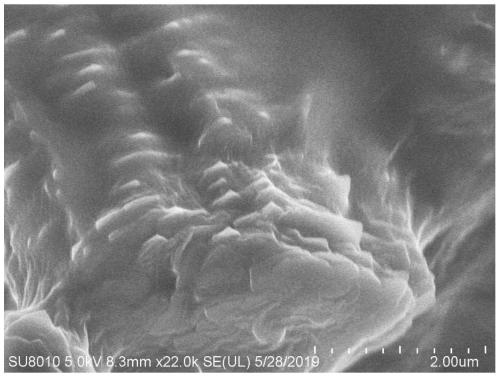

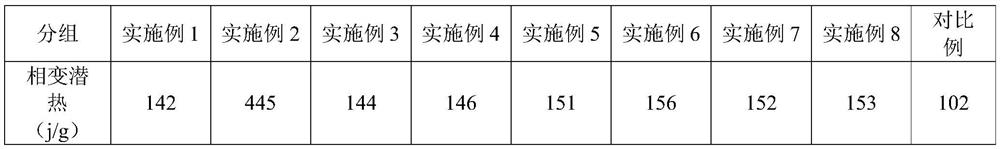

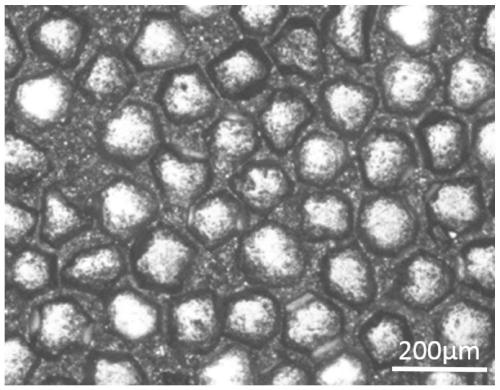

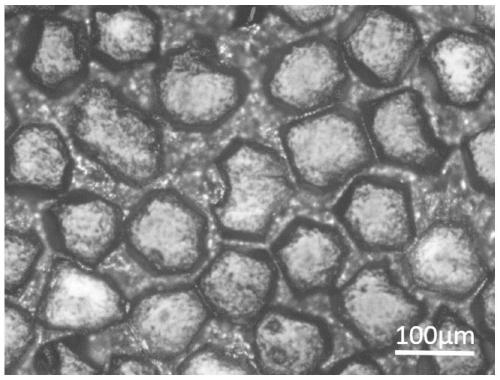

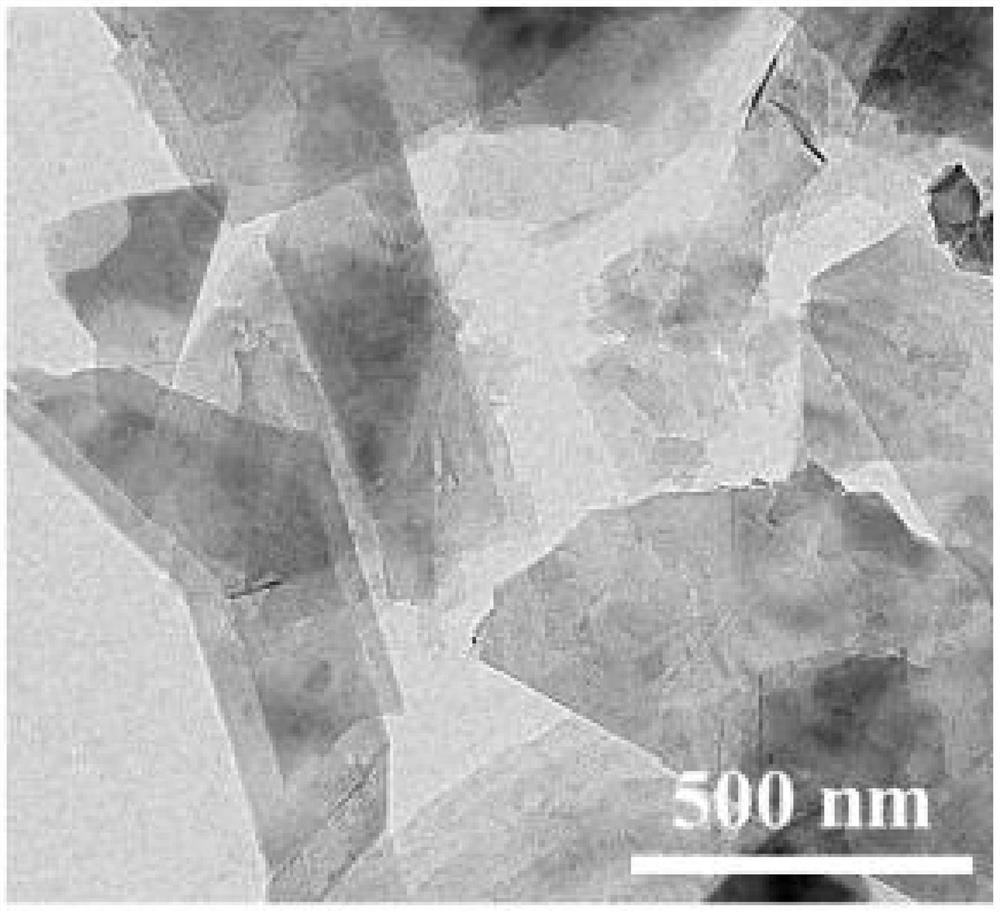

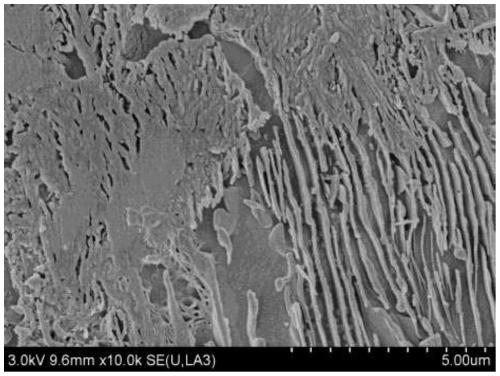

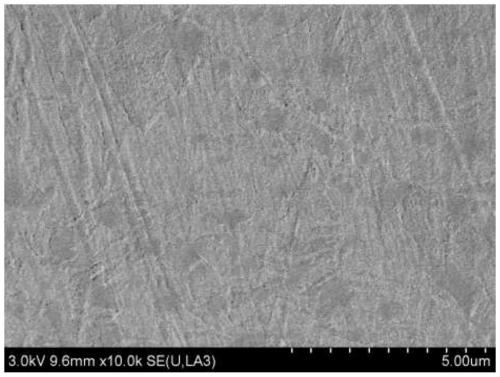

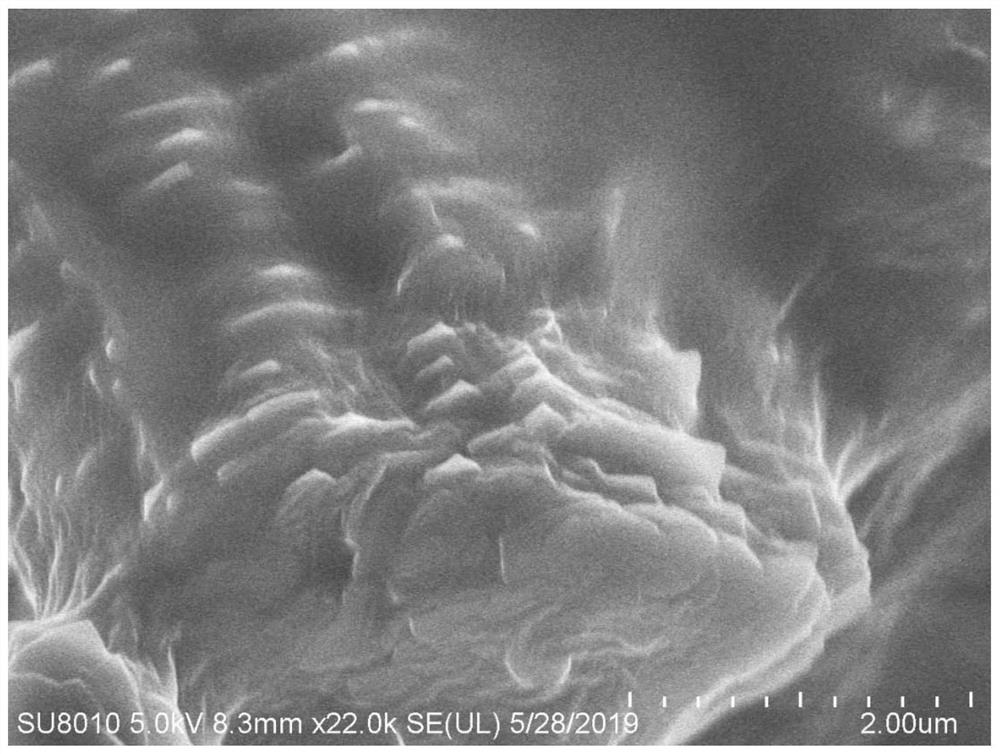

Modified graphene phase change microcapsule and preparation method thereof

InactiveCN106833541ACan not fully reflect the latent heat performanceFully reflect the latent heat performanceHeat-exchange elementsEthylenediamineGraphene

The invention discloses a modified graphene phase change microcapsule and a preparation method thereof, the microcapsule is regularly-spherical, and has a core-shell structure, the core-shell structure comprises a wall material, a core material and an emulsifier for connecting the wall material and the core material, wherein the wall material is modified graphene, the core material is a phase change material, and the mass ratio of the emulsifier, the modified graphene and the phase change material is (0.1-1.0): (0.01-0.5): 10. The modified graphene is prepared by reduction of graphene oxide with ethylenediamine, the emulsifier, the modified graphene and the phase change material are mixed, and the modified graphene-coated phase change microcapsule is prepared by ultrasonic chemistry-method. The preparation method of the phase change microcapsule is simple, the preparation cycle is short, the microcapsule morphology is regularly-spherical, the wall material is used less, and the thermal conductivity is strong.

Owner:SOUTHEAST UNIV

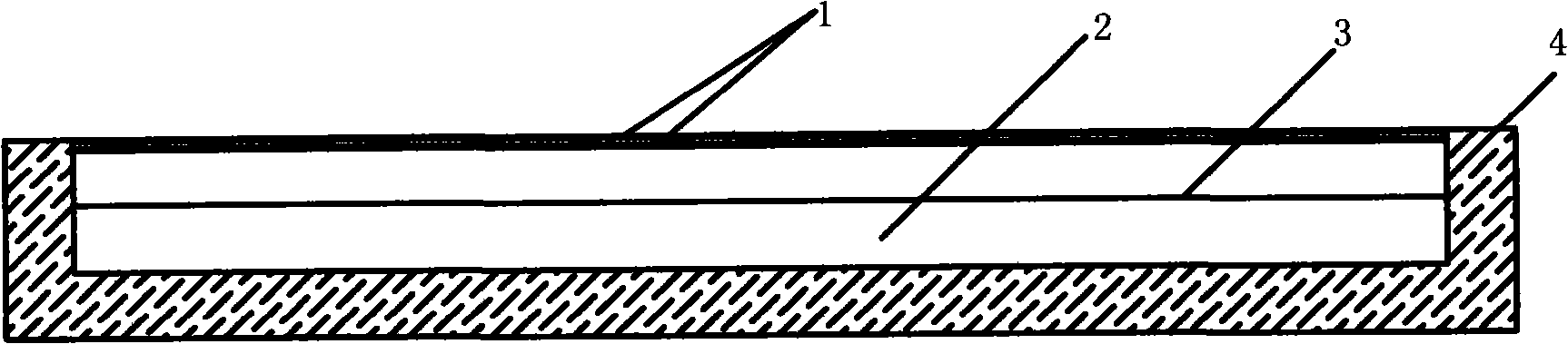

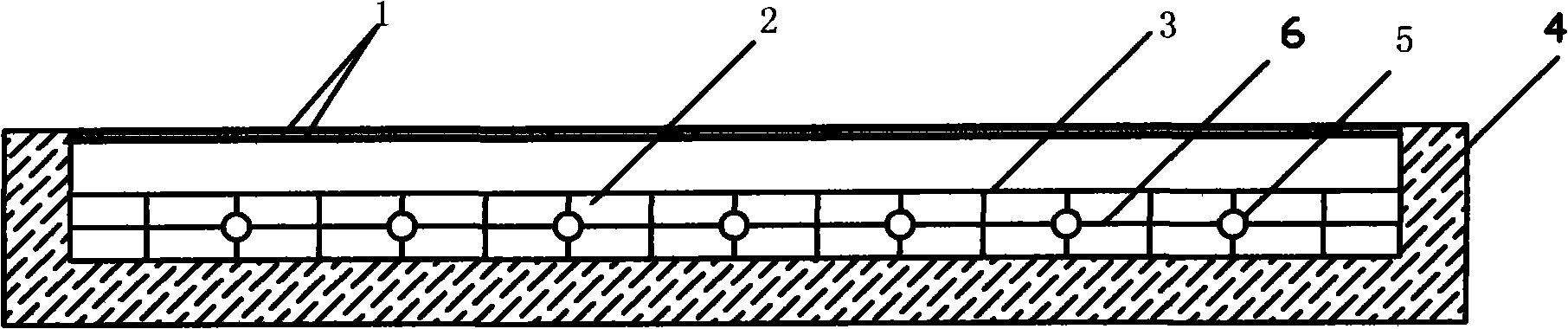

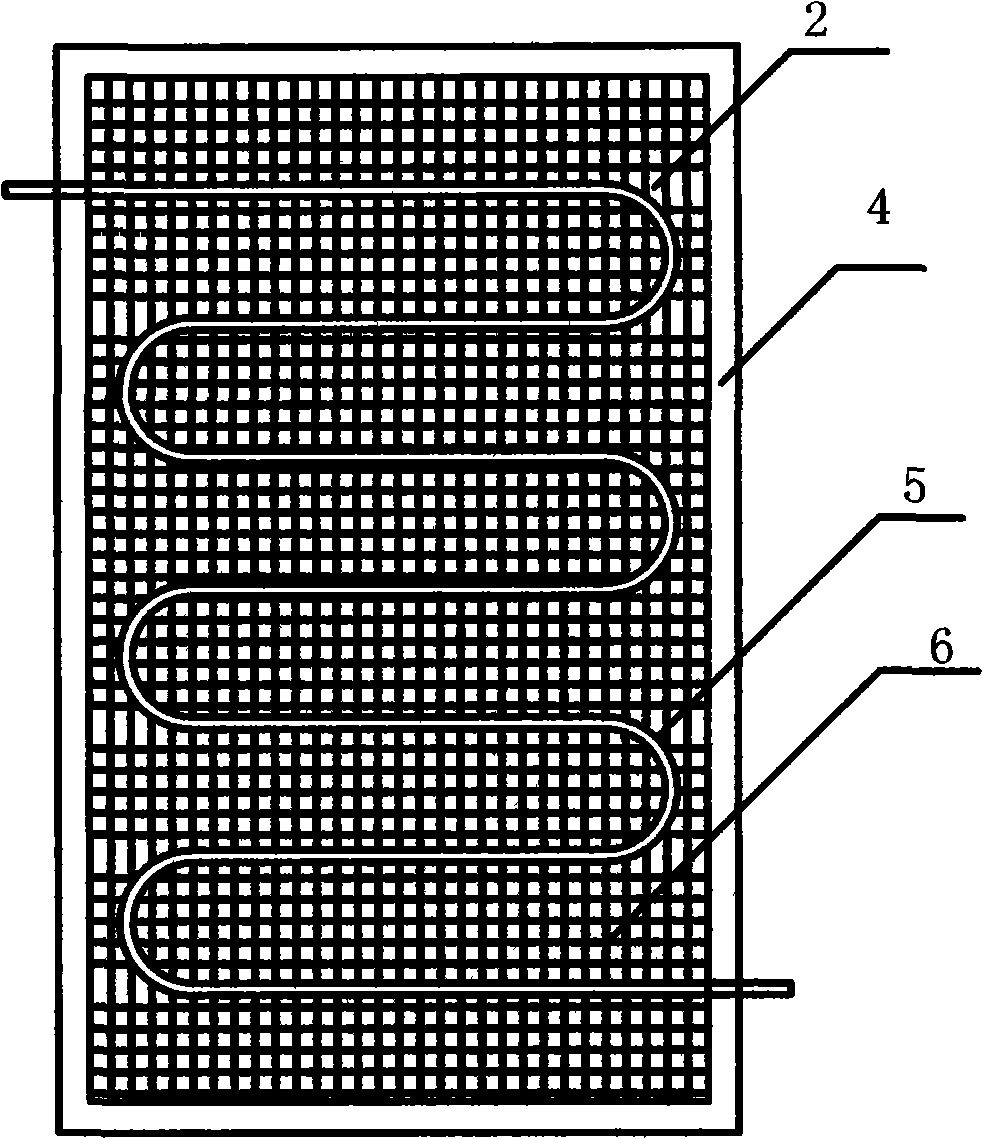

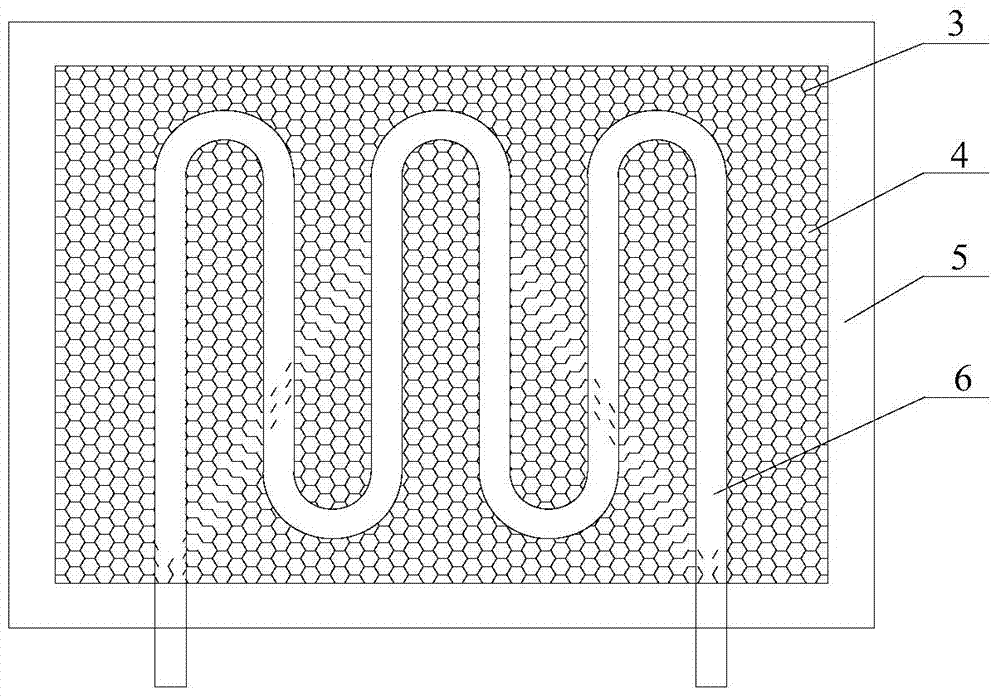

Energy storage -type solar flat-board heat collector for increasing metal fin

InactiveCN101285622ASave money and spaceSmall temperature changeSolar heat devicesHeat storage plantsPower storageHigh energy

The invention provides a power storage type solar panel heat collector provided with a metal rolling fin, relating to the solar energy technical field, in particular to the solar energy heat collector capable of storing energy technical field. The solar panel heat collector comprises a transparent material layer, a phase-change material layer, a heat absorbing plate, a heat insulating material layer, a serpentuator and heat conducting metal, wherein, the heat absorbing plate is arranged under the transparent material layer, the phase-change material layer is arranged under the heat absorbing plate, the heat insulating material layer is arranged on the periphery of the transparent material layer, the phase-change layer and the heat absorbing plate, the serpentuator and the metal rolling fin are respectively arranged inside the phase-change layer. The power storage type solar panel heat collector fulfills the purpose of good energy storing effect, high energy storing efficiency and effectively increasing the phase-change and energy-storing speed.

Owner:SOUTHEAST UNIV

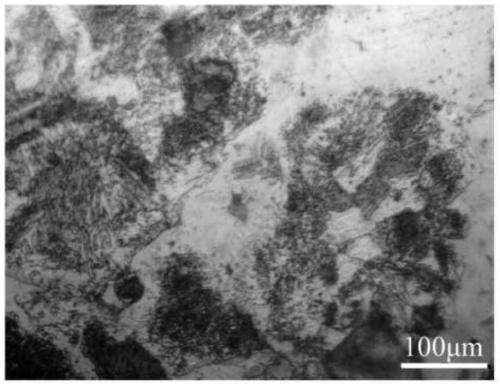

Diamond/aluminum composite material and low-cost preparation method thereof

The invention discloses a diamond / aluminum composite material and a low-cost preparation method thereof and aims to solve the problem that a diamond / aluminum composite material prepared by using the prior art has harmful interface reaction substances and is low in heat conductivity and high in preparation cost. The diamond / aluminum composite material consists of an aluminum metal and diamond powder with a filmed layer, wherein gaps of the diamond powder with the filmed layer are filled with the aluminum metal. The preparation method comprises the following steps: I, preparing a near-net forming; II, performing filming treatment on the surface of the diamond powder; III, performing air pressure infiltration preparation; IV, performing air pressure infiltration; and V, performing demolding.The density of the diamond / aluminum composite material disclosed by the invention is up to 99.8% or greater; by adopting the preparation method, an aluminum metal is saved, the interface binding strength of the diamond powder and the aluminum metal is increased, and the problem that a conventional diamond / aluminum composite material is low in heat conductivity; and the preparation method is applicable to preparation of diamond / aluminum composite materials.

Owner:HARBIN INST OF TECH

Thermal conductive graphite blocks for blast-furnace bottom and hearth

InactiveCN101993246AReduce porosityImprove thermal conductivityBlast furnace componentsBlast furnace detailsPorosityHearth

The invention provides thermal conductive graphite blocks for a blast-furnace bottom and a hearth, belonging to the technical field of carbon refractory. The raw materials of the graphite blocks comprise the following components in parts by weight: 11-15 parts of petroleum coke with grain size of more than 2mm and less than or equal to 4mm, 10-14 parts of petroleum coke with grain size of more than 1mm and less than or equal to 2mm, 53-60 parts of petroleum coke with grain seize of more than 0.075mm and less than or equal to 0.15mm, 34-40 parts of petroleum coke with grain seize of less than or equal to 0.075mm, and 22-25 parts of mesothermal asphalt. In the formula of the thermal conductive graphite blocks for the blast-furnace bottom and the hearth, high-quality needle cokes with higherintensity and easy graphitization are used, a small grain formula is adopted, and a high-pressure multi-soaking and multi-baking method is adopted, so that an impregnant can penetrate through the holes of the graphite blocks, thus reducing the porosity of the graphite blocks, improving the compactness, volume density and intensity of the products, improving the coefficient of heat conductivity and alkali-resistant corrodibility of the graphite blocks greatly, fundamentally solving the problem of low coefficient of heat conductivity of the graphite blocks, and meeting the requirement on quality of the graphite blocks with high thermal conductivity for large blast furnaces.

Owner:HENAN FANGYUAN CARBON GRP

Shaped MOF-based composite phase change material and preparation method and application thereof

ActiveCN110484213AHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsPhase changeMetal

The embodiment of the invention relates to a shaped MOF-based composite phase change material and a preparation method and application thereof. The shaped MOF-based composite phase change material comprises an MOF-based carrier and an organic phase change core material loaded on the MOF-based carrier, and the MOF-based carrier comprises foam metal and MOF covering the surface of the foam metal. According to the obtained shaped MOF-based composite phase change material, the shape and the size of the foam metal are controlled, so that the obtained shaped MOF-based composite phase change materialhas the shape and the size of the foam metal; and the foam metal is used as one part of the shaped MOF-based composite phase change material, and the foam metal has higher heat conductivity, so thatthe heat conductivity of the composite phase change material can be enhanced.

Owner:SUZHOU ADVANCED MATERIALS CO LTD

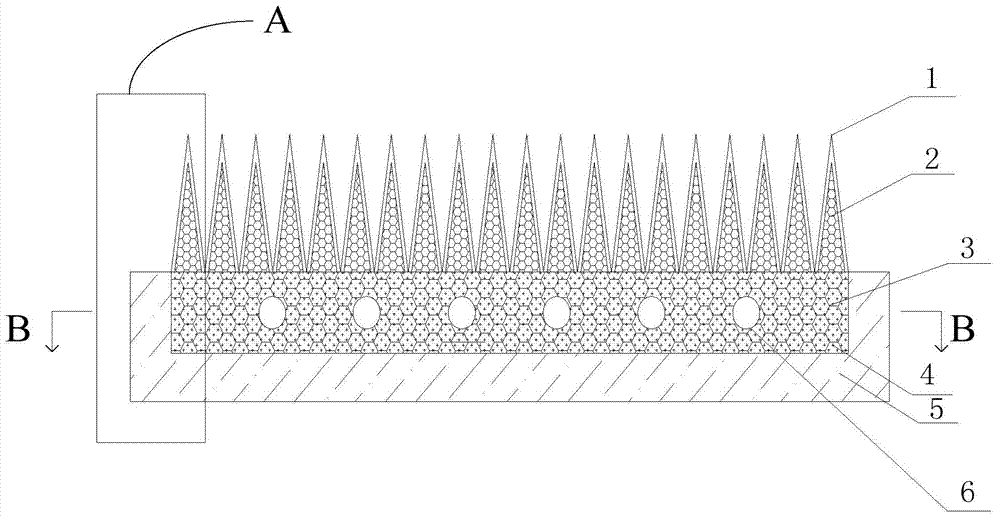

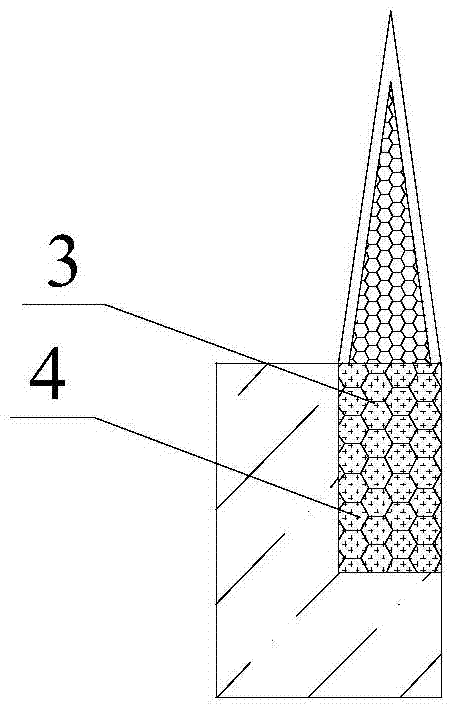

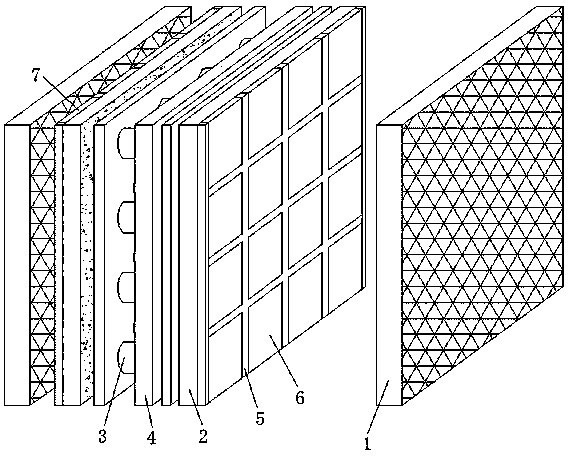

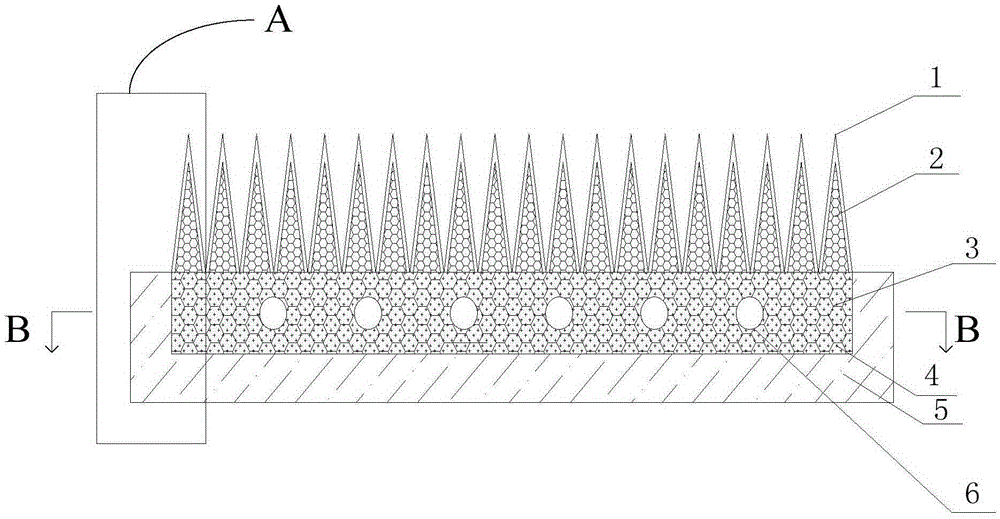

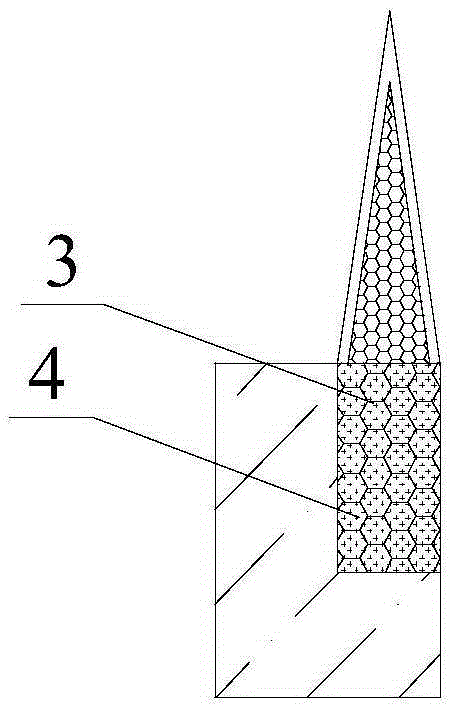

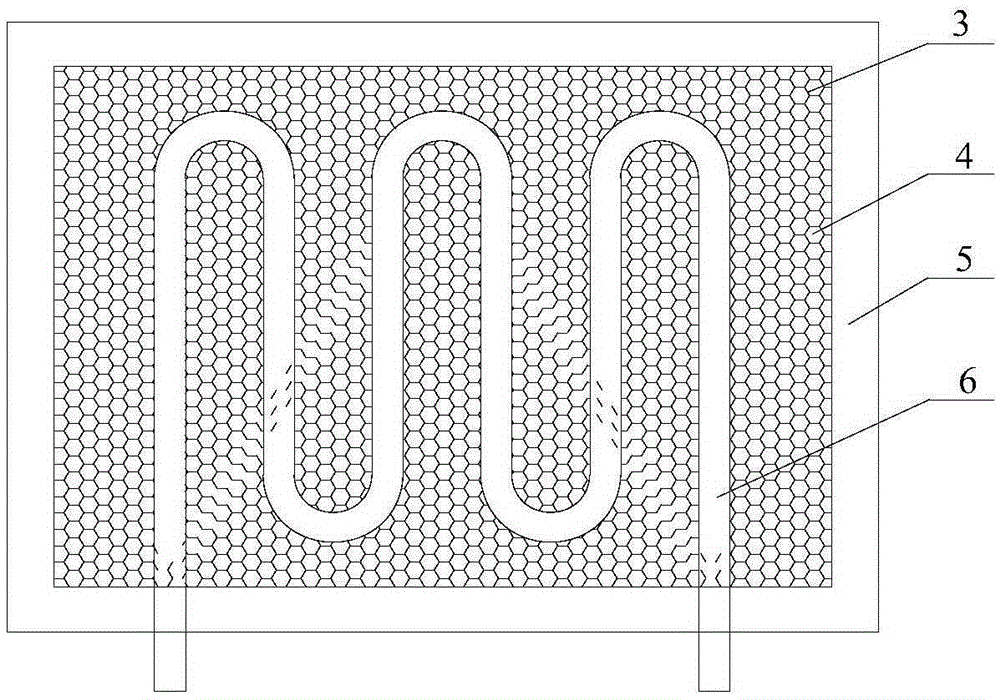

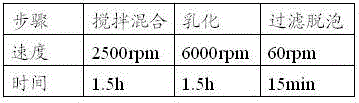

Solar heat collector with film hole structure

ActiveCN104121709AAvoid heat lossImprove energy storage capacitySolar heat devicesSolar thermal energy generationPhase-change materialTransmitted light

A solar heat collector with a film hole structure comprises a heat preservation box with the upper end open, a phase-change material layer is arranged in the heat preservation box, a coiled pipe is arranged in the phase-change material layer, a conical metal foam layer is arranged at the top of the phase-change material layer, the outer wall of the conical metal foam layer is wrapped by a transparent outer layer which can transmit light, and metal foam is added into the phase-change material layer. The content of air in a heat collecting area is greatly increased due to the metal foam structure, an air layer is divided into parts with small volumes, and therefore heat loss caused by convection is prevented. Sunlight can illuminate the conical metal foam layer through the transparent outer layer, the conical metal foam layer has the function of a heat absorber and converts light energy into heat energy, and the transparent outer layer has the function of a heat insulating layer and prevents heat in the heat absorber from being dissipated to the outside. The solar heat collector can effectively absorb solar radiation and fast store the energy and can be widely used for drying, food processing, household heat supplying , cooking and the like.

Owner:XI AN JIAOTONG UNIV

Scratch-resistant black heat transfer printing ink and preparation method thereof

ActiveCN103725090AAnti-scratch guaranteeDoes not affect heat dissipationInksAnodic oxidationChemistry

The invention discloses a scratch-resistant black heat transfer printing ink and a preparation method thereof. The printing ink comprises the following components in percent by weight: 25-35 percent of epoxy resin, 5-8 percent of phenolic resin, 3.5-5.0 percent of a curing agent, 45-60 percent of a heat conducting filling material, 10-12 percent of a coloring agent and 0.5-0.7 percent of an additive. The printing ink has a rigidity larger than 6 H after being roasted and pressed to meet the scratch-resistant requirement of Al-based copper-clad plate production and manufacturing, has the thermal conductivity reaching 1.5 W to facilitate the radiating of an Al-based copper-clad plate compared with an anodic oxidation film and a PET protecting film, and has a maximum bearing temperature of 230 DEG C and maximum pressure of 100 kg / cm<2>, and therefore, a novel method for using the heat transfer printing ink is found, the radiating function of the Al-based copper-clad plate is not affected while the aluminium surface is prevented from scratching. The heat transfer printing ink is a new measure for protecting the aluminium surface of the Al-based copper-clad plate.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

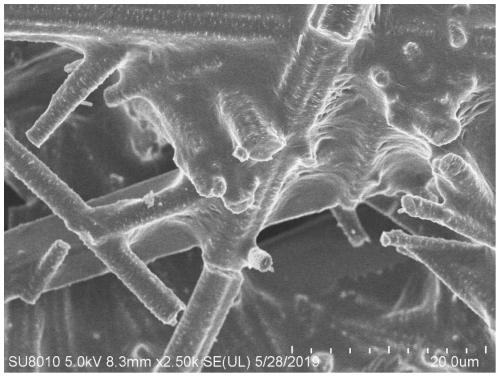

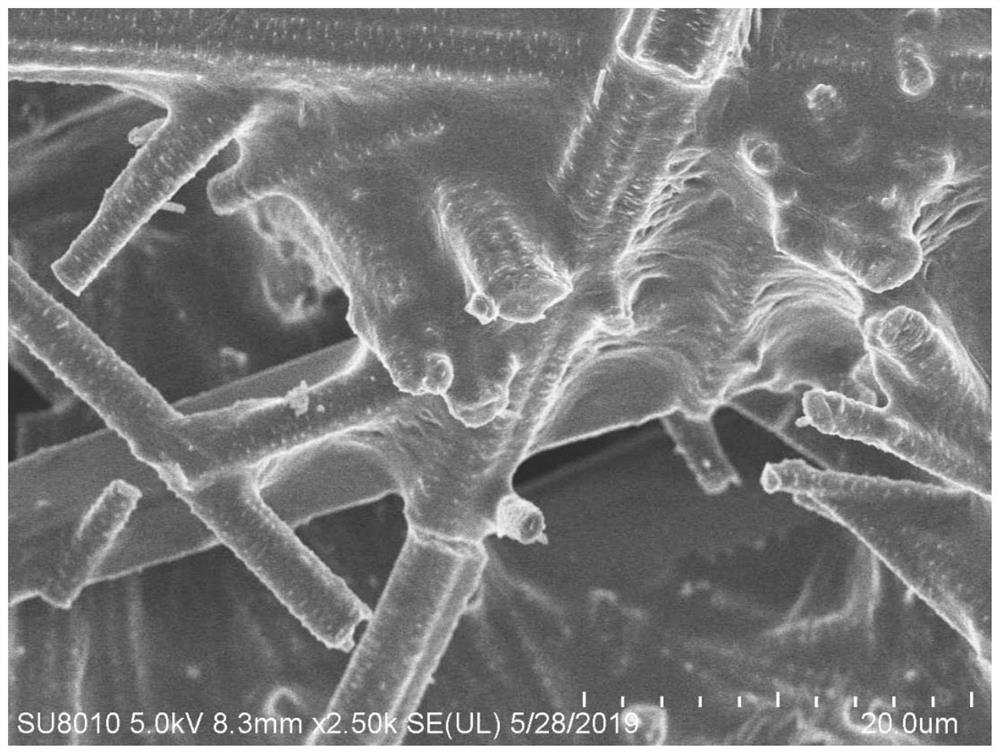

Liquid absorbing core and supporting column integrated structure flat plate heat pipe based on carbon nano tube array

PendingCN107764117AImprove thermal conductivityHigh thermal conductivityIndirect heat exchangersWorking fluidCarbon nanotube

The invention discloses a liquid absorbing core and supporting column integrated structure flat plate heat pipe based on a carbon nano tube array. The liquid absorbing core and supporting column integrated structure flat plate heat pipe based on the carbon nano tube array comprises an upper metal cover plate, a lower metal cover plate and upper and lower metal cover plate liquid absorbing core andsupporting column integrated structures generated on the inner sides of the upper metal cover plate and the lower metal cover plate; the upper metal cover plate and the lower metal cover plate form aclosed cavity by means of edge sealing, and the vacuumized closed cavity is internally filled with work liquid; the upper and lower metal cover plate liquid absorbing core and supporting column integrated structures comprise thin-layer carbon nano tubes growing on the inner surfaces of the metal cover plates and a plurality of vertical carbon nano tubes continuously growing in specific areas of the thin-layer carbon nano tubes, and the thin-layer carbon nano tubes and the vertical carbon nano tubes form flat plate heat pipe capillary cores and flat plate heat pipe supporting columns correspondingly; and the upper and lower metal cover plate supporting columns are arranged in a staggered manner, and the liquid absorbing core and supporting column integrated structure with a staggered arrangement type is formed. The liquid absorbing core and supporting column integrated structure flat plate heat pipe based on the carbon nano tube array has the beneficial effects of being high in heat conductivity, small in size, small in weight and the like, the heat transfer performance of the flat plate heat pipe can be guaranteed, and the mechanical strength safety during heat pipe running can also be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

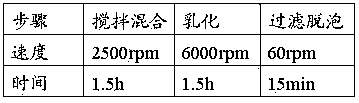

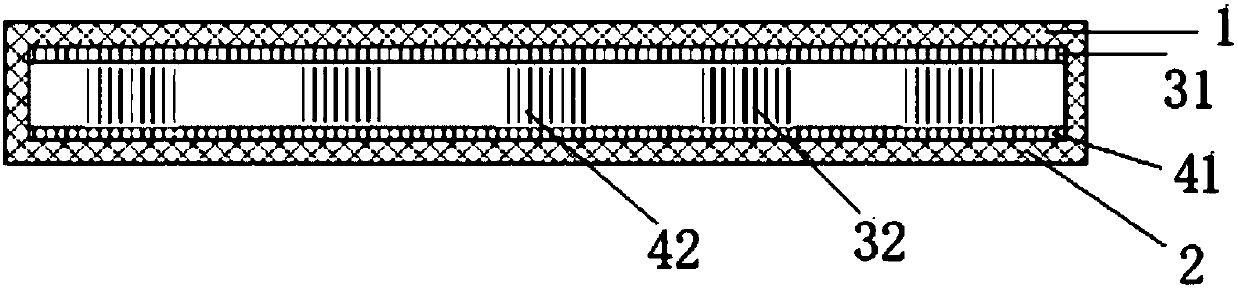

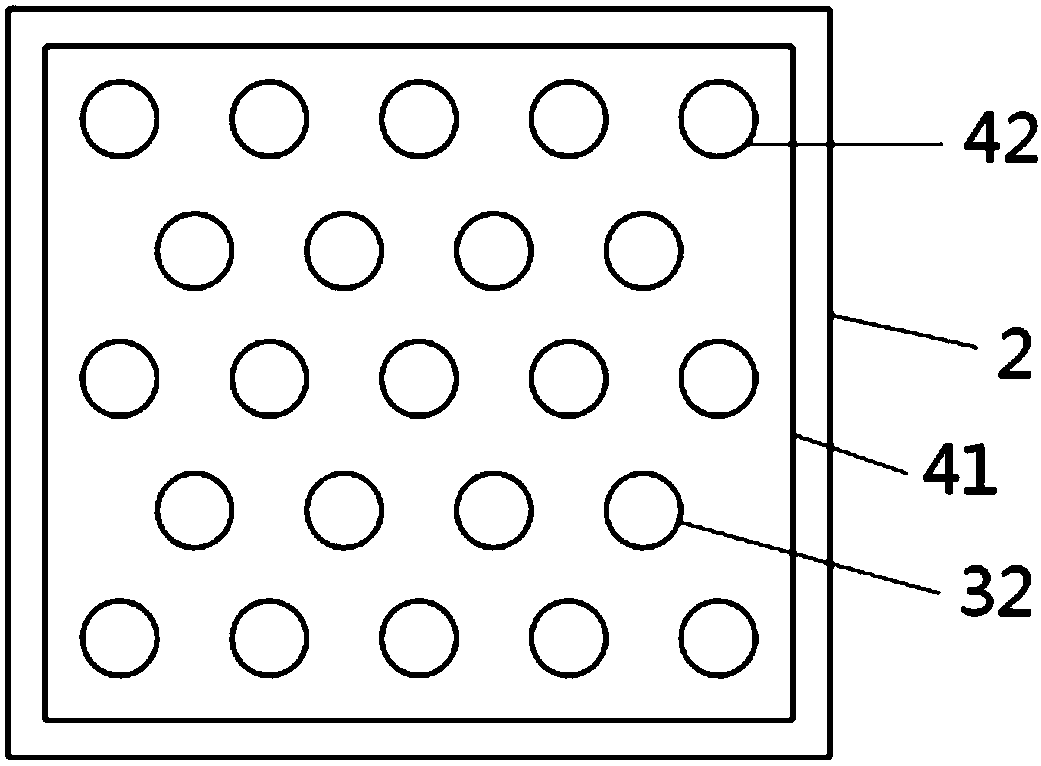

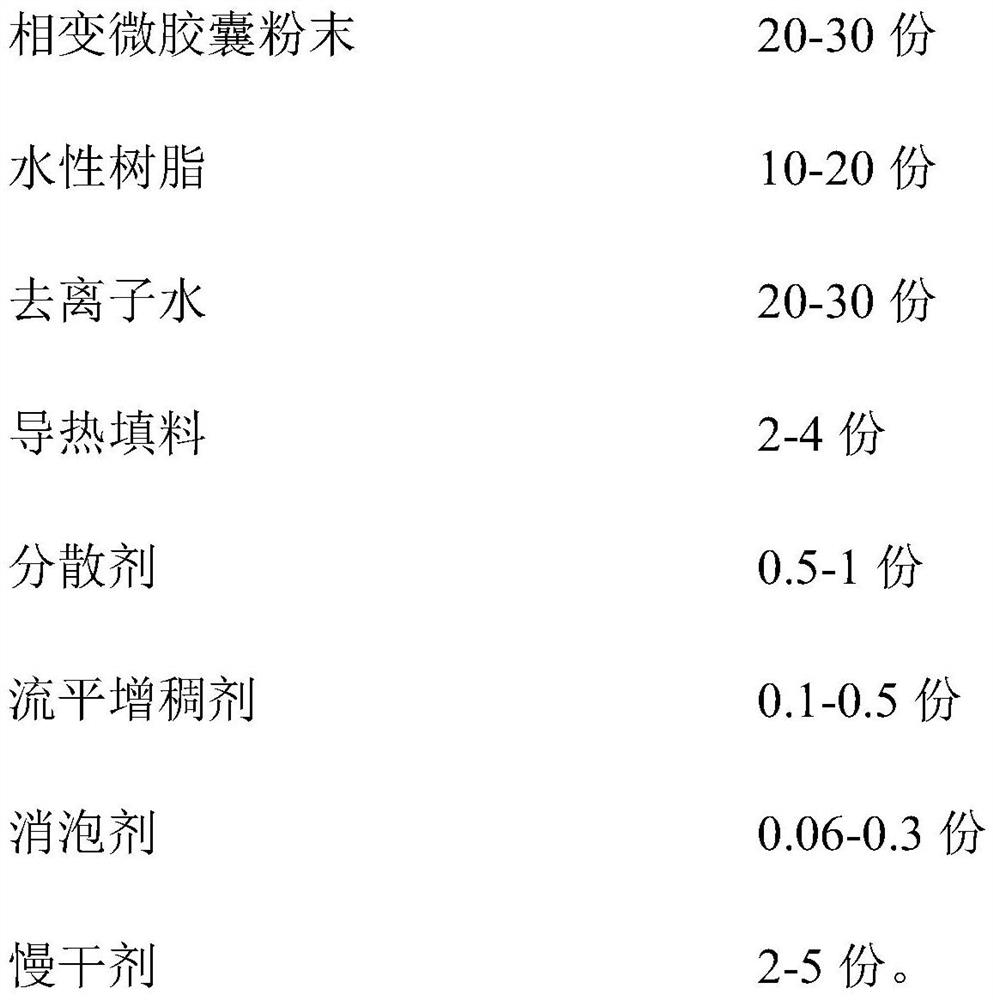

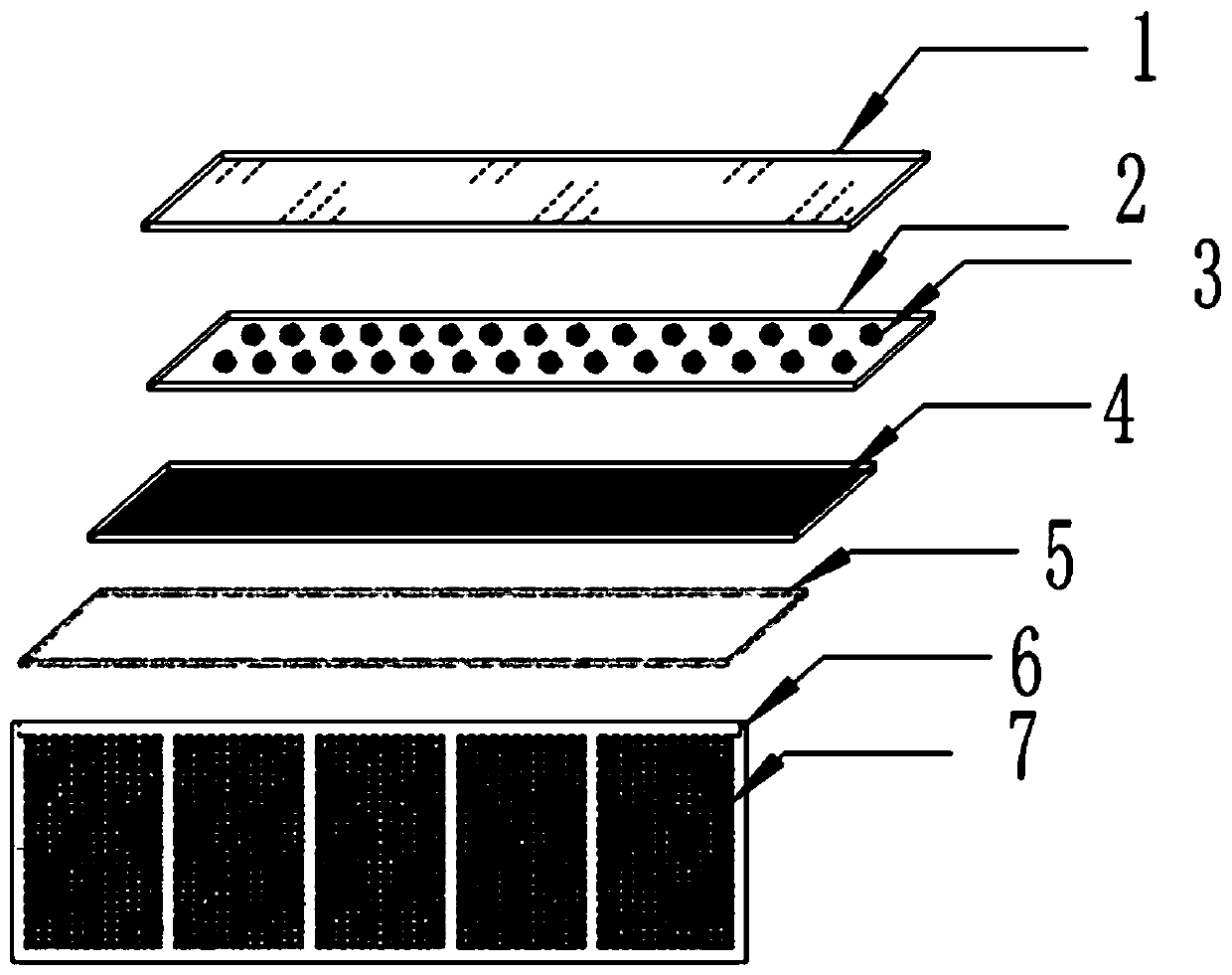

High-performance water-based phase change coating and preparation method thereof

InactiveCN111909579AGood dispersionIncrease the addition ratioUnspecified rubber coatingsHeat-exchange elementsPhysical chemistryDefoaming Agents

The invention provides a high-performance water-based phase change coating and a preparation method thereof. The high-performance water-based phase change coating is prepared from, by weight, 20-30 parts of phase change microcapsule powder, 10-20 parts of water-based resin, 20-30 parts of deionized water, 2-4 parts of heat conduction filler, 0.5-1 part of dispersing agent, 0.1-0.5 part of levelingthickener, 0.06-0.3 part of defoaming agent and 2-5 parts of slow drying agent; the preparation method comprises the following steps: performing ultrasonic stirring on the dispersing agent and the deionized water, adding the defoaming agent to obtain a dispersion liquid, adding the water-based resin, the leveling thickener and the slow drying agent to the dispersion liquid, and defoaming the mixture to obtain the phase-change coating. According to the invention, the phase-change microcapsule powder content in the phase-change coating is high, the enthalpy value of the dried coating is high, the heat conductivity is high, and the problem of poor stability is solved.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

Heat conducting glue for high-power LED encapsulation and preparation method thereof

InactiveCN103045101AReduce thermal resistance potentialSolve the problem of low thermal conductivityNon-macromolecular adhesive additivesInorganic adhesivesWaferingSoluble glass

The invention relates to the field of solar PV utilization, in particular to a heat conducting glue for the high-power LED encapsulation and a preparation method thereof. The method is characterized is in that a soluble glass Na2O / NSiO2 is adopted as a heat conducting base body, the mode number N is 3.5, and deionized water is utilized to prepare a soluble glass colloidal sol with concentration of 45 percent. The preparation method comprises the following steps: and using a magnetic stirring apparatus to stir the soluble glass colloidal sol to be uniform, and then conducting 40-50 min of ambient-temperature ultrasonic oscillation. The method has the benefits that the problem that the thermal conductivity of the heat conducting glue for encapsulation material is low is solved; the problems that the wafer is in failure and the thermal conductivity is greatly reduced because a traditional heat conducting glue has high probability of falling-off of the wafer, is easily separated and is easy to separate from heat conducting fillers, are eased. The method has the advantages of inexpensive raw materials, simple preparation technology, higher high-thermal conductivity of the heat conducting glue, complete satisfaction of high-power LED encapsulation heat radiating requirement, and better market outlook.

Owner:郝勇

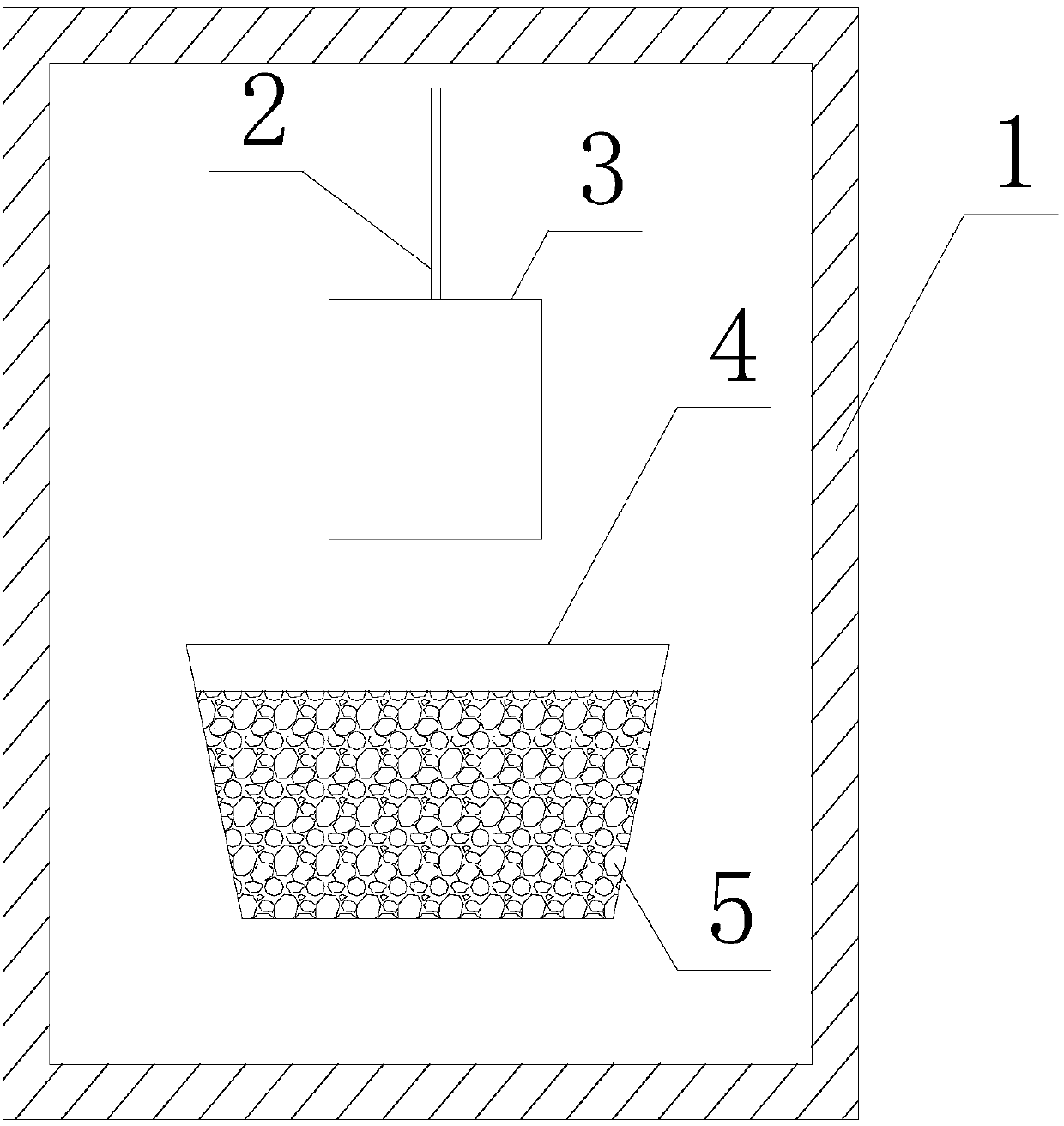

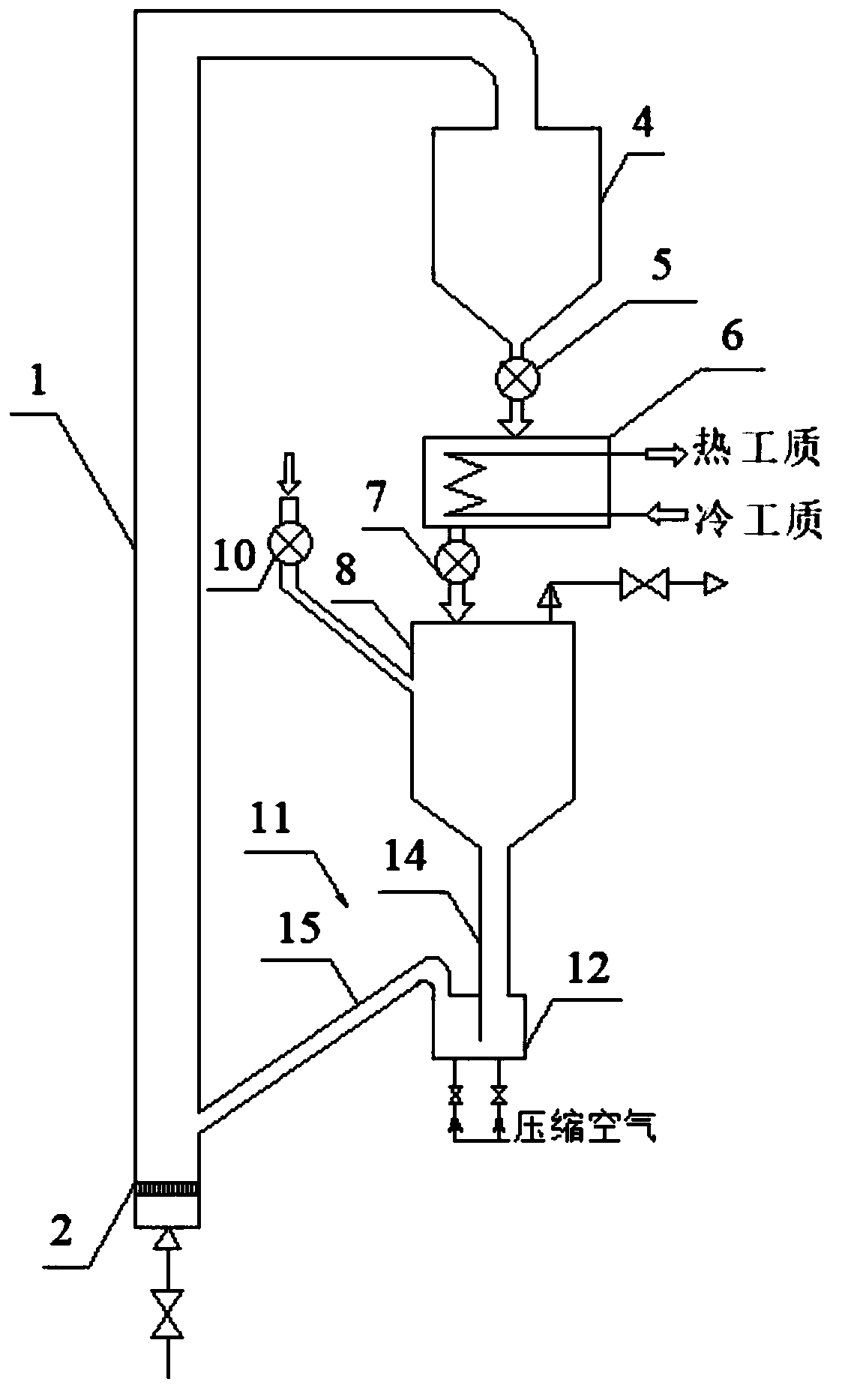

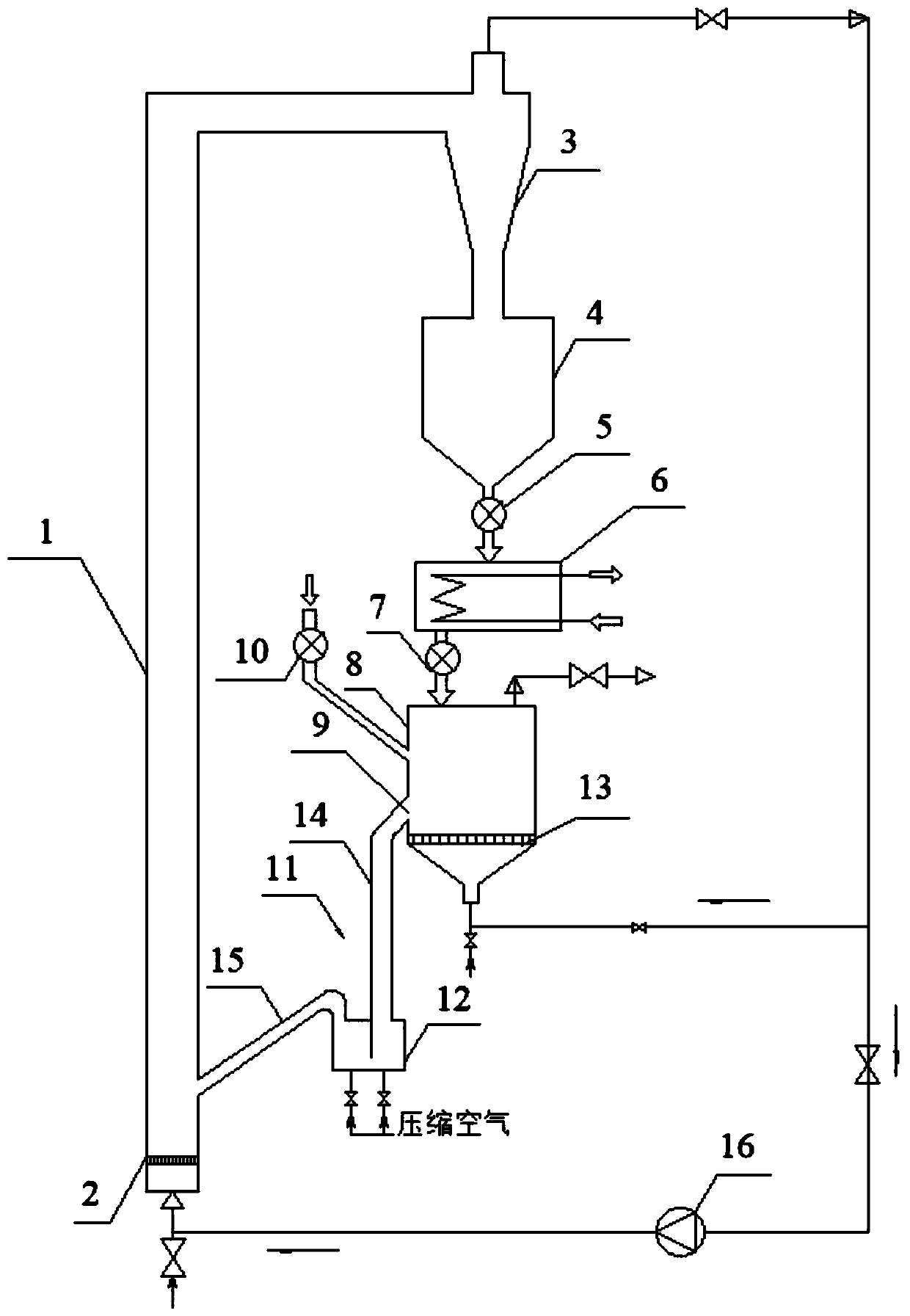

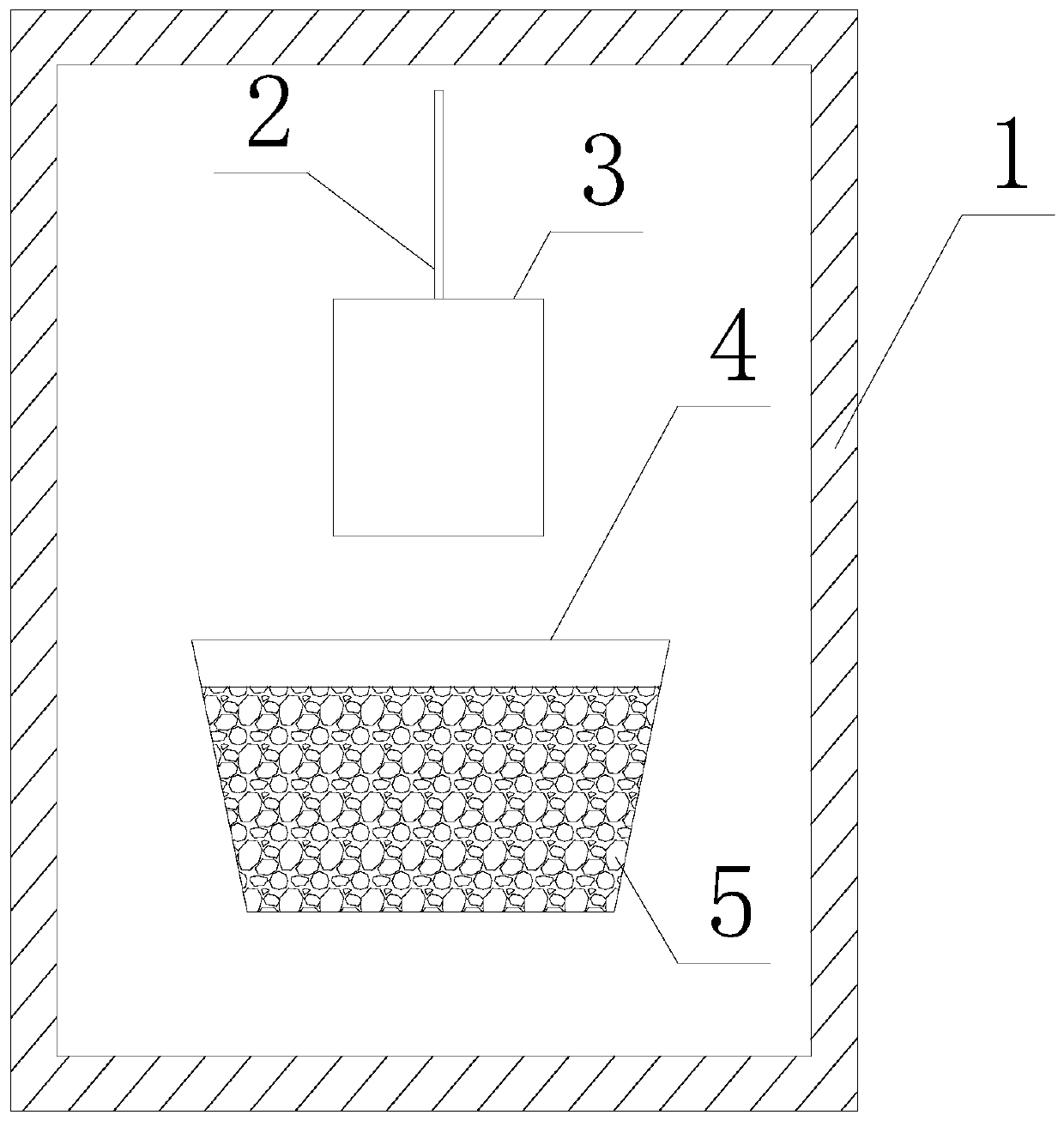

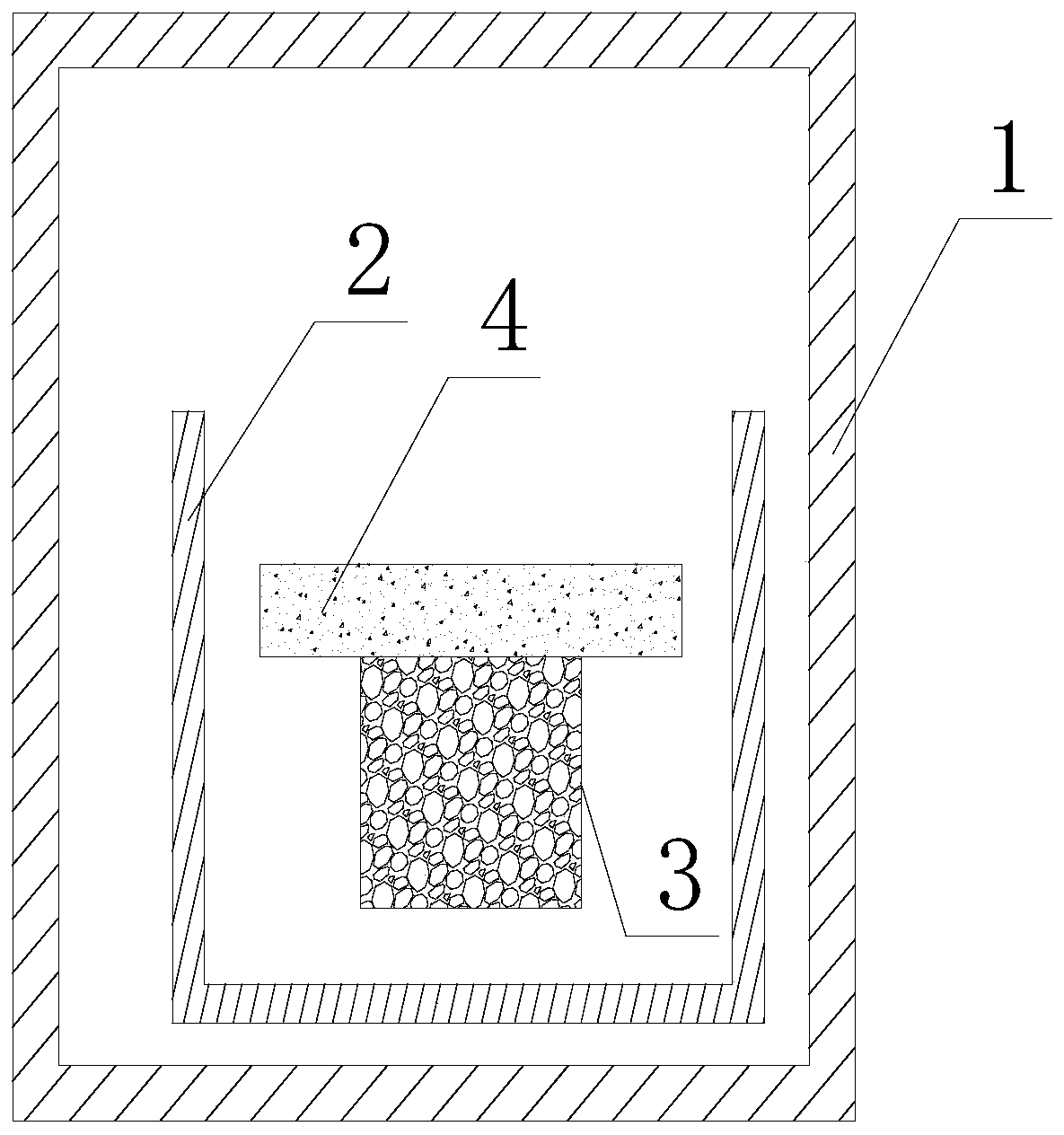

Solid medium energy storage system and method based on fluidized bed heating

InactiveCN110360862ASolve the problem of low thermal conductivityImprove wind power absorption capacityHeat storage plantsHigh temperature storageFluidized bed

The invention discloses a solid medium energy storage system and method based on fluidized bed heating. The solid medium energy storage system based on fluidized bed heating comprises a heating lifting chamber, a high temperature storage tank, a heat exchange device and a low temperature storage tank which are sequentially connected. High-temperature resistant solid particles such as sand are usedas an energy storage and heat exchange medium of the system. The heating lifting chamber is selected and used as a fluidized bed heating lifting device; and a heating air distribution device is arranged at the bottom of the heating lifting chamber. The upper part of the low temperature storage tank is provided with a feeding device, and the lower part is provided with an overflow port. A returning device is arranged between the low temperature storage tank and the heating lifting chamber. A cold state solid heat storage medium is fed into the low temperature storage tank through the feeding device, is fed into the heating lifting chamber from the low temperature storage tank through the returning device, and is fluidized and heated to become a high temperature solid heat storage medium, and the high temperature solid heat storage medium is stored in the high temperature storage tank. When the high temperature solid heat storage medium is needed, the high temperature solid heat storagemedium is subjected to heat exchange for utilization through the heat exchange device. A low temperature solid heat storage medium obtained after heat exchange is stored in the low temperature storage tank. The solid medium energy storage system has the advantages of simple technical requirements, high comprehensive utilization rate of energy sources and the like.

Owner:TSINGHUA UNIV +1

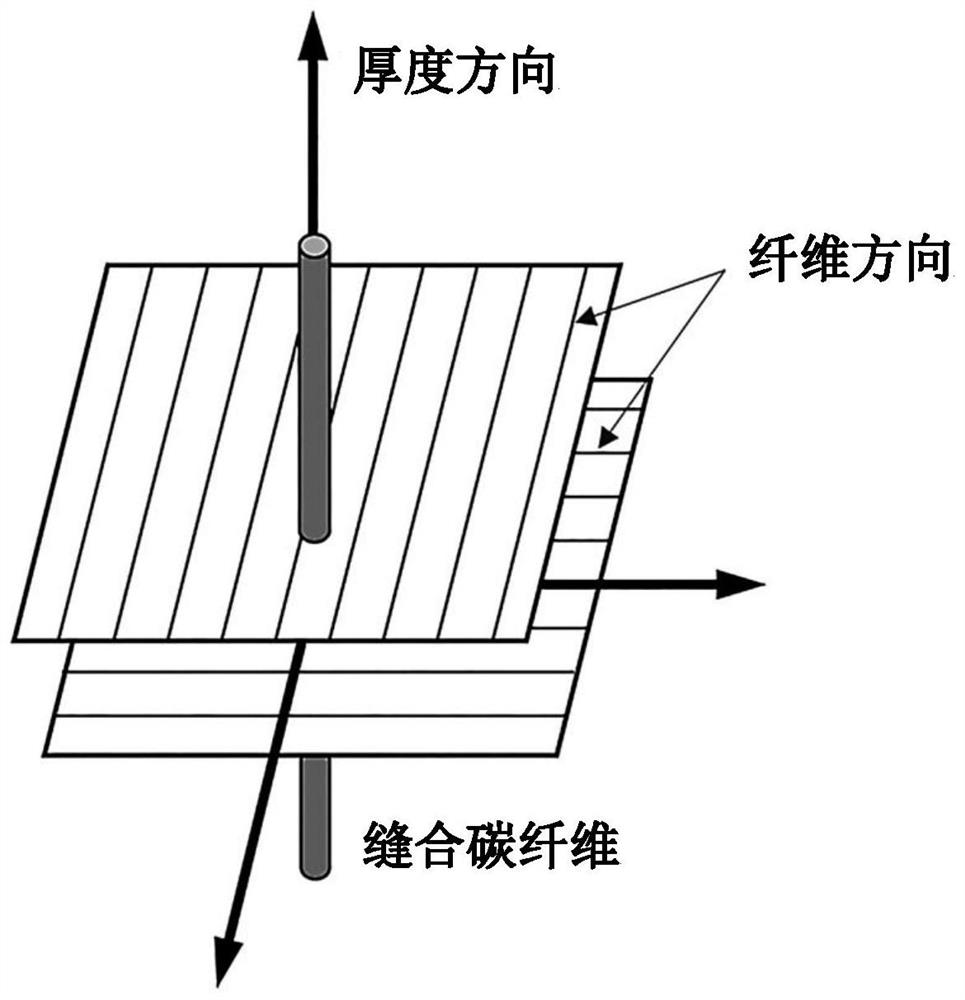

Fiber reinforced composite structure comprising stitch-member and the method for producing the same

PendingCN111746062ASolve the problem of low thermal conductivityLamination ancillary operationsLaminationFiber-reinforced compositeCarbon fiber reinforced composite

The present specification provides a carbon fiber reinforced composite structure comprising: a plurality of carbon fiber reinforced sheets, which are laminated; and a stitch member penetrating one ormore carbon fiber reinforced sheets, in which the carbon fiber reinforced sheet includes a plurality of reinforcing carbon fibers arranged in one direction. The carbon fiber reinforced composite structure shows excellent thermal conductivity in a thickness direction.

Owner:KOREA INST OF SCI & TECH

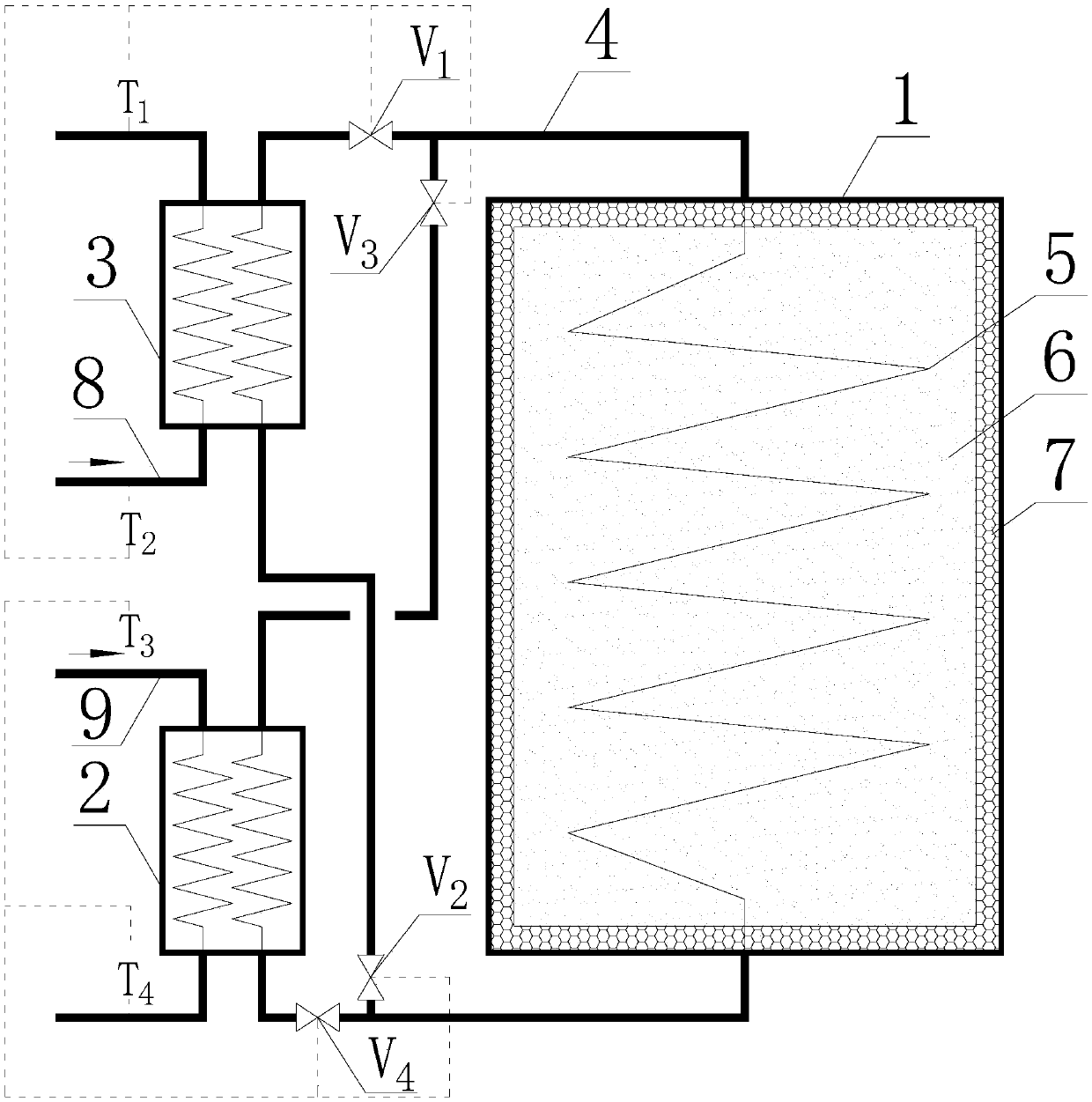

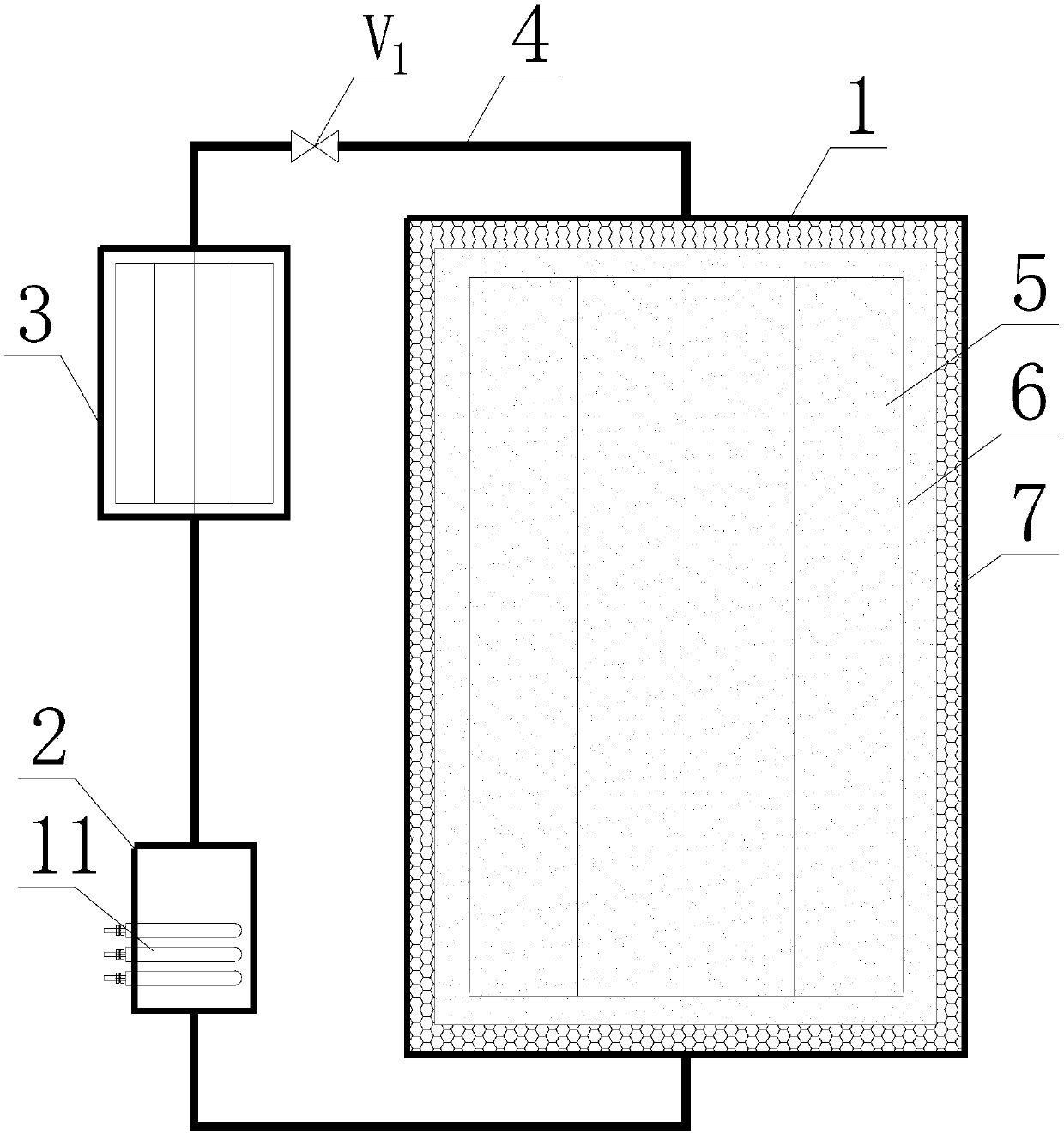

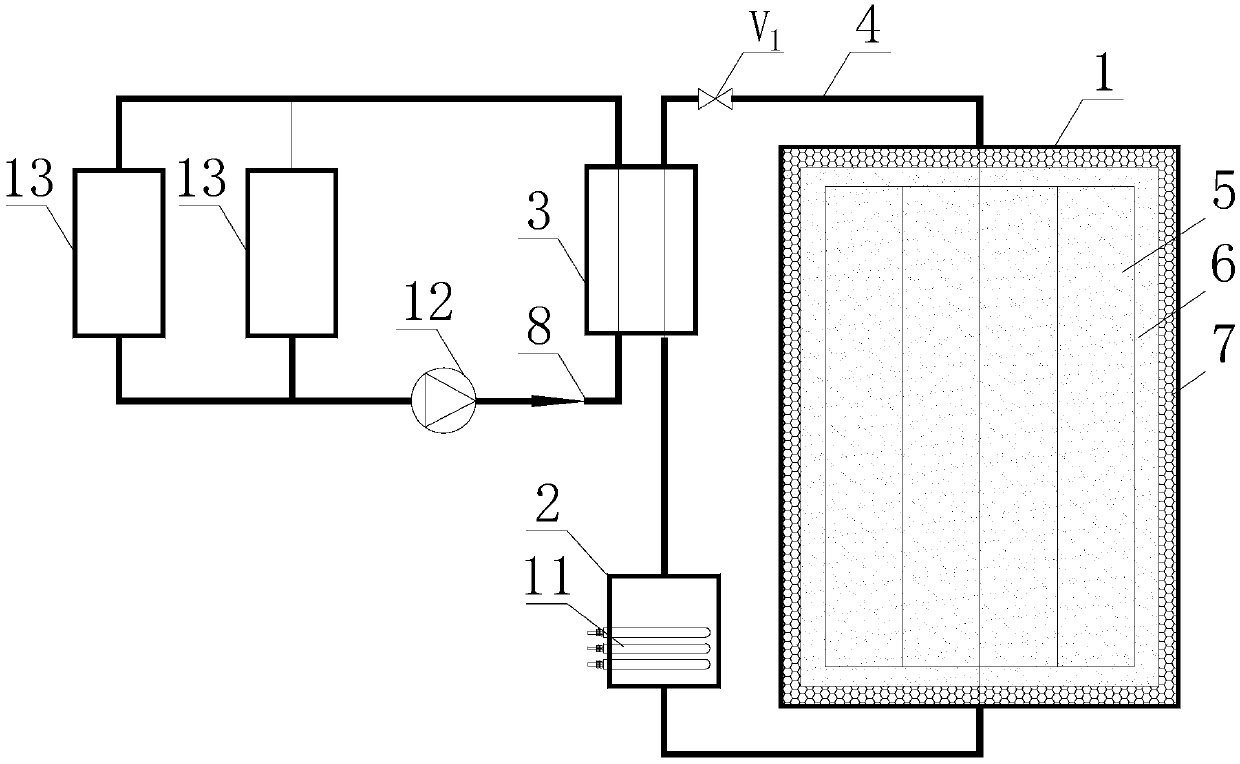

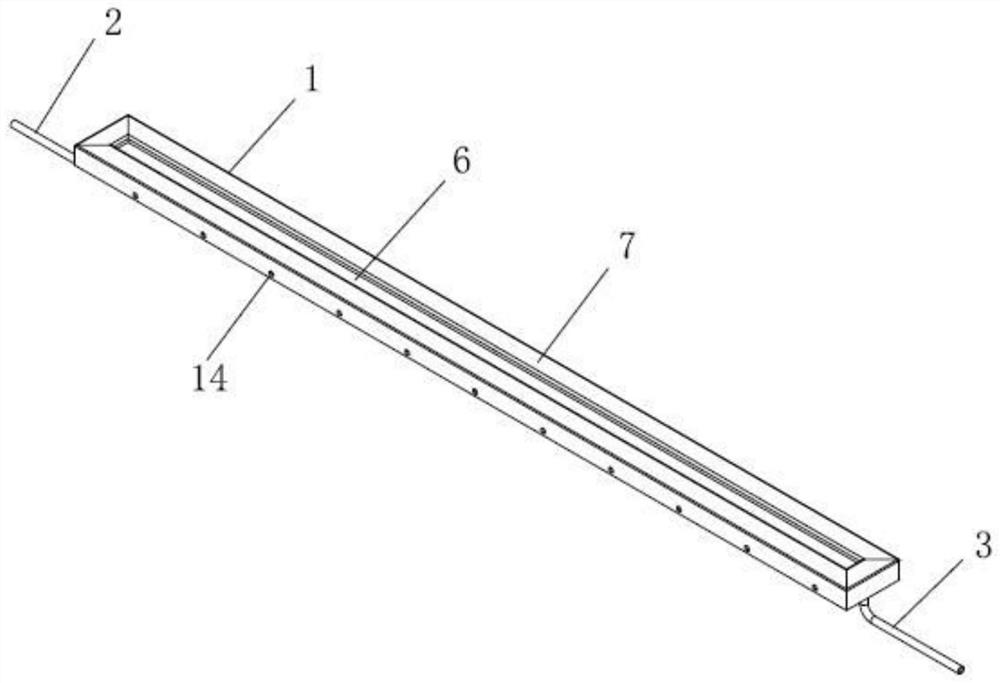

Energy storage device utilizing temperature difference self-driving loop

PendingCN107843135ASolve the problem of low thermal conductivitySolve supply problemsHeat storage plantsThermal energyTemperature difference

The invention discloses an energy storage device utilizing a temperature difference self-driving loop. The energy storage device comprises low-level heat exchanger, a high-level heat exchanger, a heatexchanging pipe, a connecting pipeline, an energy storage material and a heat-insulating layer. During energy storage, cold energy or heat energy is transmitted to a circulating working medium in theclosed-type self-driving heat exchanging loop through the high-level heat exchanger or the low-level heat exchanger, then the circulating working medium transmits the cold energy or the heat energy to the energy storage material through the heat exchanger pipe, and the cold energy or the heat energy is stored. During energy releasing, the circulating working medium in the closed-type self-drivingheat exchanging loop absorbs the cold energy or the heat energy stored in the energy storage material through the heat exchanging pipe, and the cold energy or the heat energy is released through thelow-level heat exchanger or the high-level heat exchanger. According to the cold storage and heat storage device, the heat energy and the cold energy such as waste heat (cold), valley electric storedheat and stored cold, and solar energy can be stored and released, self-driving operation without power consumption can be achieved, the energy storage device is suitable for various places where theheat energy and the cold energy need to be stored, and the problem that supply and demand of the heat energy and the cold energy are not matched in the aspect of time is solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A kind of diamond/aluminum composite material and its low-cost preparation method

Owner:HARBIN INST OF TECH

High-thermal-conductivity and low-expansion conductive pattern board and preparation method therefor

InactiveCN105390474AImprove thermal conductivityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesBreakdown strengthElectrical conductor

The invention belongs to the technical field of electronic packaging and particularly relates to a high-thermal-conductivity and low-expansion conductive pattern board and a preparation method therefor. The preparation method comprises: by taking a high-thermal-conductivity and low-expansion composite material as a base material, preparing a high-thermal-conductivity insulation medium layer on single or both surfaces of the base material with a physical or chemical method of welding, gluing, chemical vapor deposition, magnetron sputtering or physical vapor deposition; and finally depositing a conductor circuit pattern layer on the insulation medium layer with a chemical vapor deposition technology, a magnetron sputtering technology, a physical vapor deposition technology or an etching method so as to obtain the lamellar high-thermal-conductivity and low-expansion conductive pattern board. The conductive pattern board has the properties of high breakdown strength, high dielectric constant and the like in addition to high thermal conductivity, low expansion coefficient, high strength and high size stability; and a conductor circuit pattern is directly formed on a substrate, so that a preparation process for the conductor circuit pattern layer is simplified.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

A kind of diamond/aluminum composite material and high-efficiency preparation method thereof

Owner:HARBIN INST OF TECH

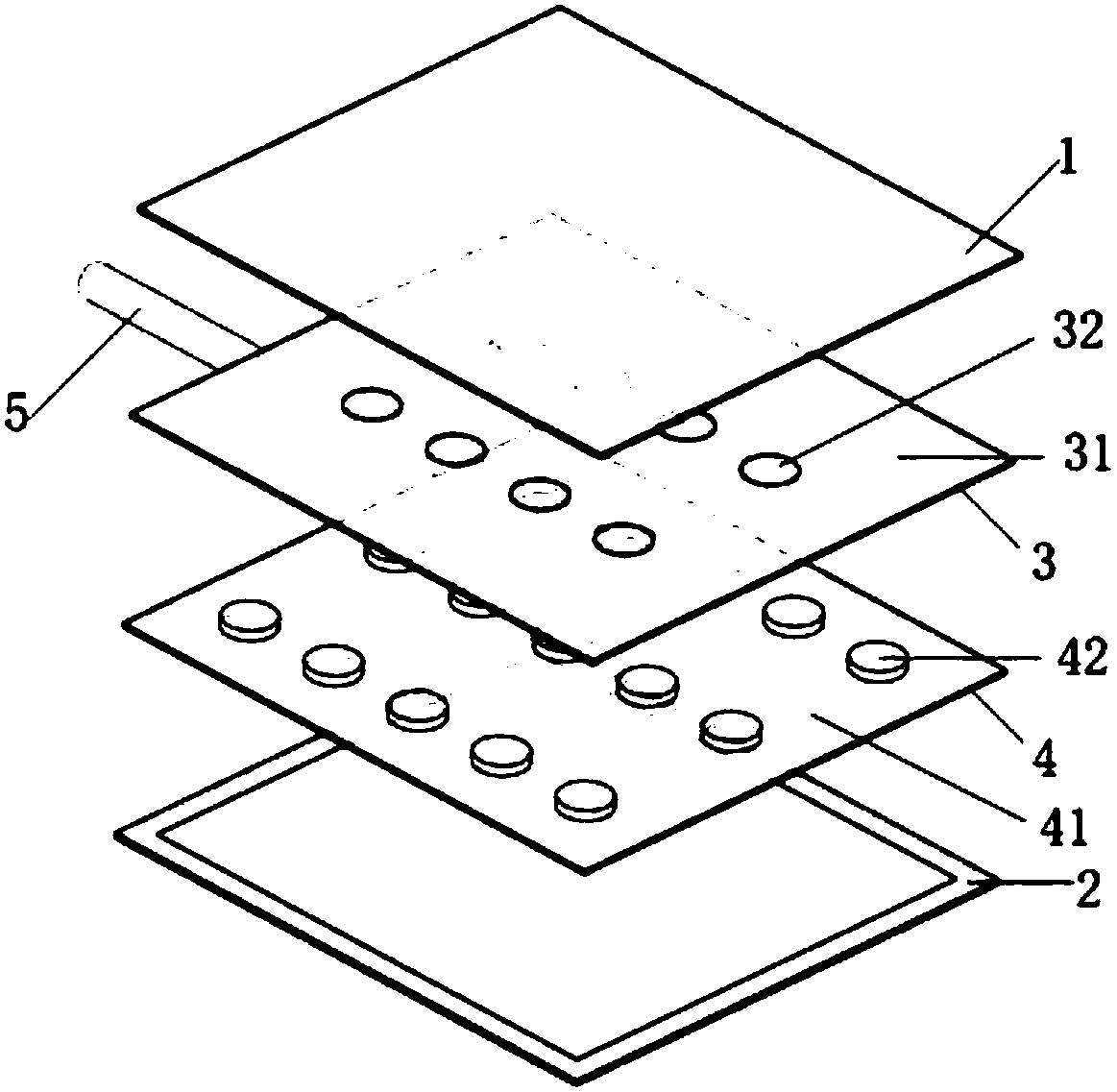

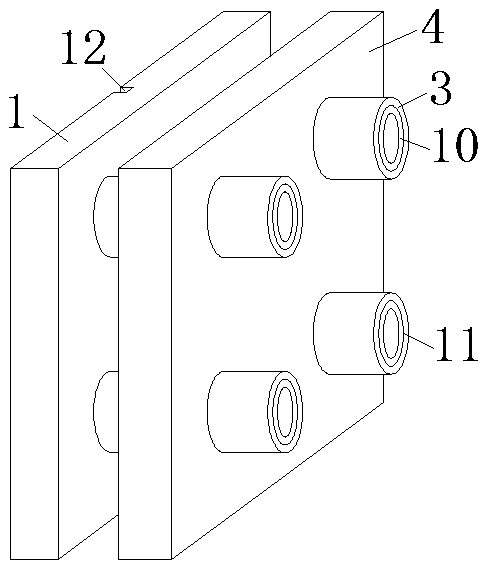

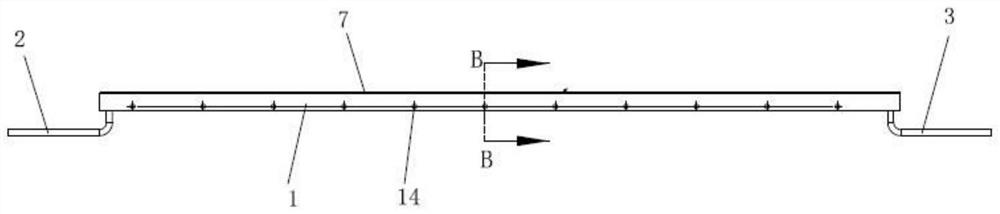

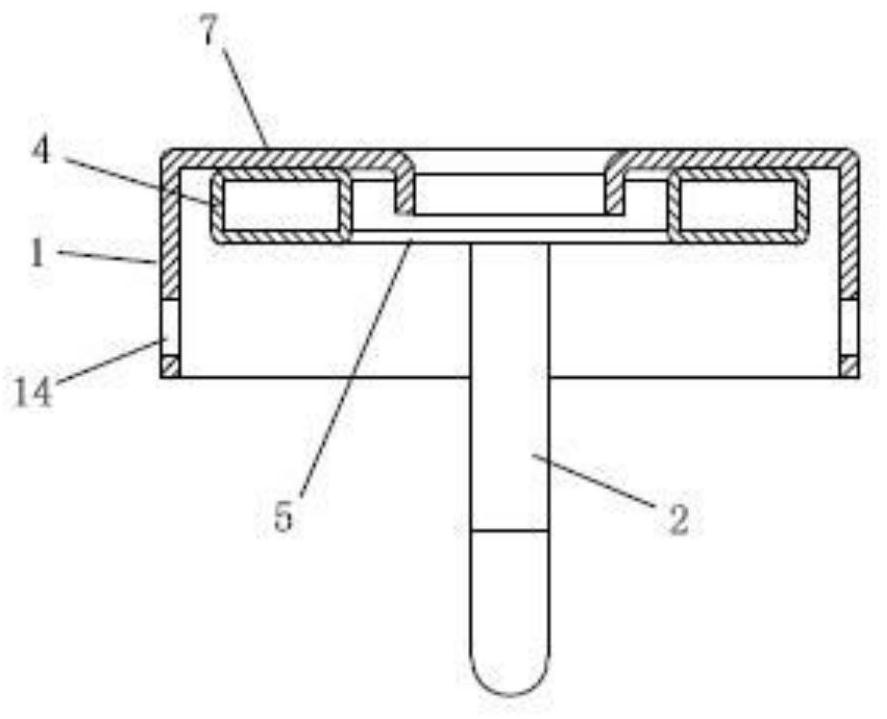

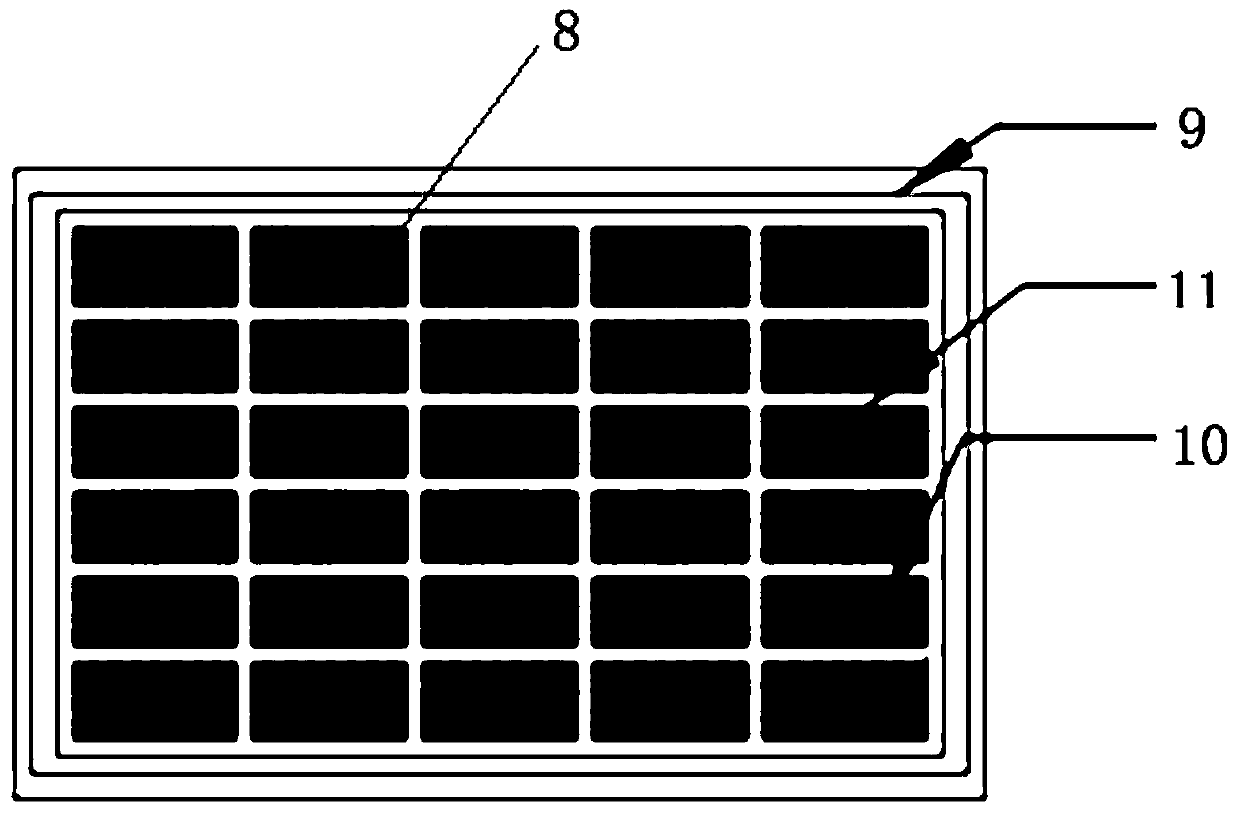

Bipolar plate of proton exchange membrane fuel cell with uniform thermal conductivity

ActiveCN109768285ASolve the problem of low thermal conductivityStay conductiveCell electrodesFuel cellsThermal conductivityEngineering

The invention belongs to the technical field of fuel cells, in particular to a bipolar plate of a proton exchange membrane fuel cell with uniform thermal conductivity. The bipolar plate comprises a diffusion layer and a catalytic layer, wherein opposite surfaces of the diffusion layer and the catalytic layer are fixedly connected through phase change heat conduction insulating tubes that are distributed in a rectangular array between the diffusion layer and the catalytic layer, the central outer surfaces of the phase change heat conduction insulating tubes are fixedly sleeved with proton exchange membranes that are located between the diffusion layer and the catalytic layer, and reverse surfaces of the diffusion layer and the catalytic layer are fixedly mounted with positioning frames. Thebipolar plate of the proton exchange membrane fuel cell with uniform heat conduction, by fixedly connecting the opposite surfaces of the diffusion layer and the catalytic layer through the phase change heat conduction insulating tubes, achieves the effect of guiding and conducting the heat inside the diffusion layer and the catalytic layer and prevents the accumulation of heat in the diffusion layer and the catalytic layer from adversely affecting the battery, thereby solving the technical problem of low thermal conductivity of the existing fuel cell.

Owner:BEIJING UNIV OF CHEM TECH

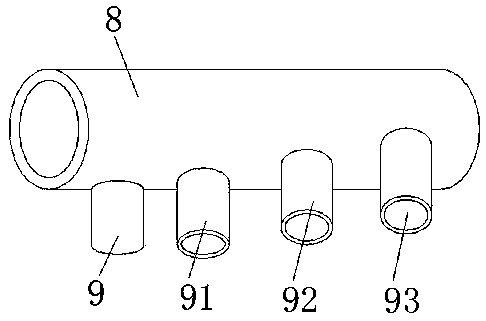

Vapor chamber plate radiator

PendingCN112739148AService life is not affectedReduce thermal resistanceModifications by conduction heat transferEngineeringMechanical engineering

The invention discloses a vapor chamber radiator. The radiator comprises a radiator main body, a liquid absorption core, radiating fins and a cold liquid working medium, the radiator main body comprises a vapor chamber shell and a vapor chamber cover plate, the vapor chamber cover plate is fixedly connected to the side surface of the vapor chamber shell, and the radiating fins are fixedly connected to the outer part of the radiator main body; and the cold liquid working medium and the liquid absorption core are arranged in the radiator main body. According to the vapor chamber plate radiator, the radiator is manufactured on the basis of the vapor chamber plate, so the problem that a traditional radiator is low in heat conduction coefficient is well solved; a substrate of a common profile radiator is replaced with a uniform temperature plate structure to improve the heat conduction performance of the substrate of the profile radiator, a single-point heat source relatively concentrated by diodes is rapidly conducted and distributed to the side surface of a substrate, and then the heat is dissipated in a natural heat dissipation mode of heat dissipation tooth pieces, so that the heat conductivity coefficient of the radiator in use is greatly improved, the overall structure is simple, and the radiator is relatively practical in use.

Owner:GUIYANG AVIATION MOTOR

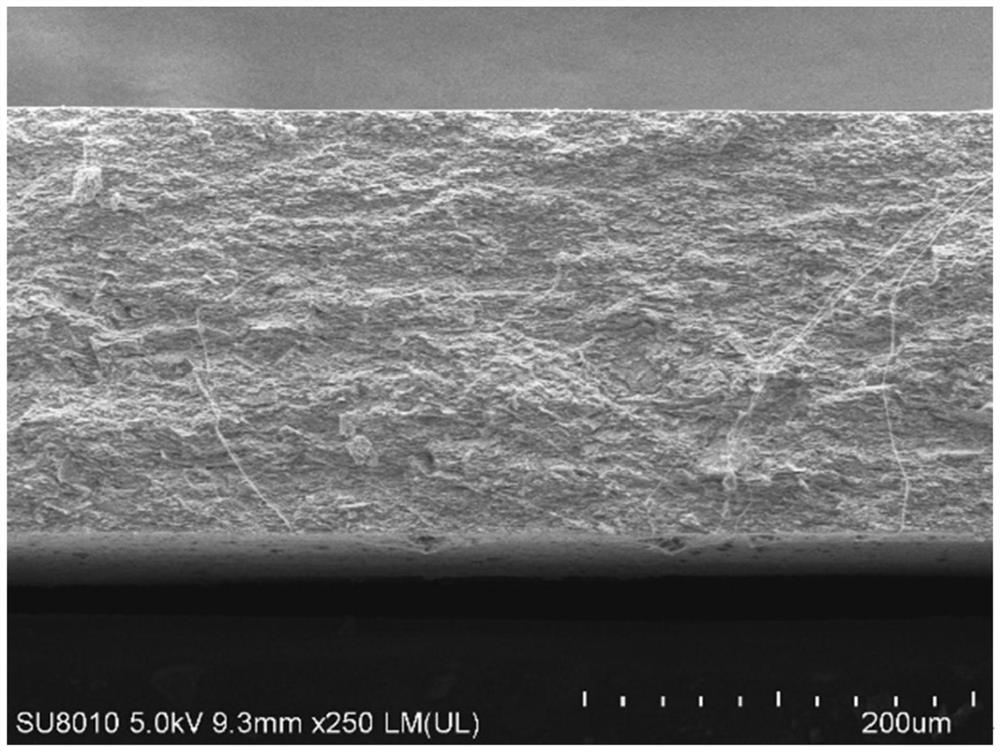

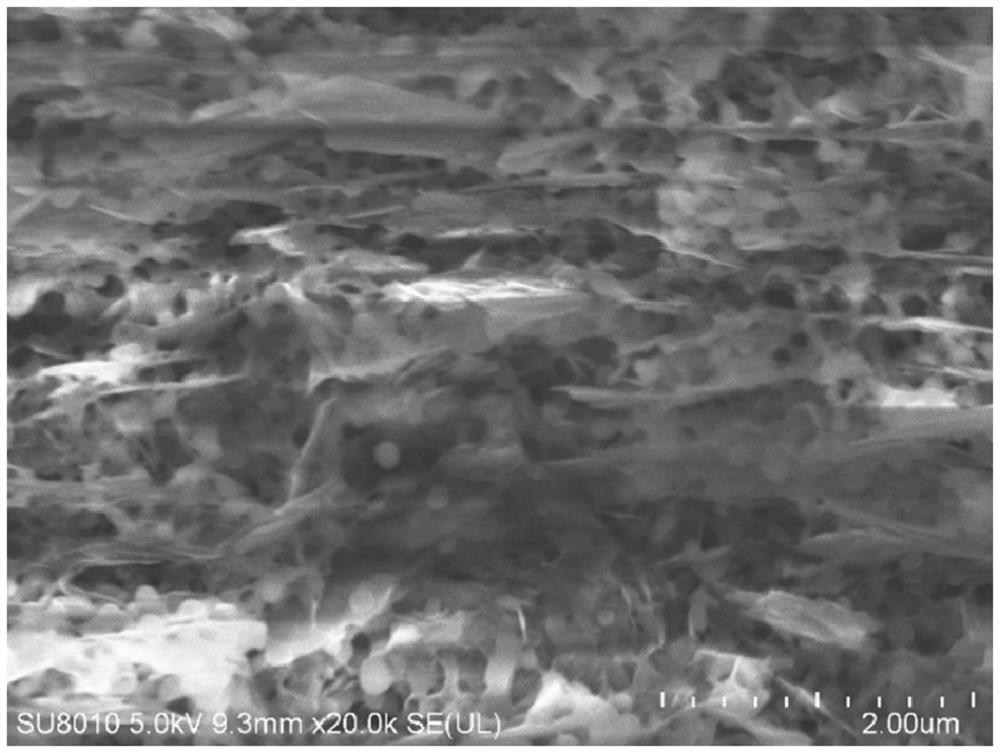

High-thermal-conductivity and low-dielectric composite material and preparation method thereof

PendingCN113980307ASolve the problem of low thermal conductivityHeat-exchange elementsDielectric lossThermal conductivity

The invention discloses a preparation method of a high-thermal-conductivity and low-dielectric composite material. The preparation method comprises the following steps: providing a boron nitride nanosheet dispersion liquid and a polytetrafluoroethylene dispersion liquid; mixing the boron nitride nanosheet dispersion liquid and the polytetrafluoroethylene dispersion liquid to obtain a mixed dispersion liquid; drying the mixed dispersion liquid to obtain mixed slurry; carrying out hot rolling treatment on the mixed slurry to obtain a mixed film; and sintering the mixed film to obtain the high-thermal-conductivity and low-dielectric composite material, wherein the high-thermal-conductivity and low-dielectric composite material comprises polytetrafluoroethylene and boron nitride nanosheets distributed in the polytetrafluoroethylene, and the boron nitride nanosheets are in lap joint end to end to form a plurality of layers of continuous heat conduction channels. The invention further provides the high-thermal-conductivity and low-dielectric composite material prepared by the preparation method of the high-thermal-conductivity and low-dielectric composite material. The high-thermal-conductivity and low-dielectric composite material disclosed by the invention not only has relatively high thermal conductivity, but also has extremely low dielectric constant and dielectric loss and excellent machinability and mechanical properties.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

A kind of solar heat collector with film hole structure

ActiveCN104121709BImprove thermal conductivityIncrease contentSolar heat devicesSolar thermal energy generationLight energyMetal foam

A solar heat collector with a film hole structure comprises a heat preservation box with the upper end open, a phase-change material layer is arranged in the heat preservation box, a coiled pipe is arranged in the phase-change material layer, a conical metal foam layer is arranged at the top of the phase-change material layer, the outer wall of the conical metal foam layer is wrapped by a transparent outer layer which can transmit light, and metal foam is added into the phase-change material layer. The content of air in a heat collecting area is greatly increased due to the metal foam structure, an air layer is divided into parts with small volumes, and therefore heat loss caused by convection is prevented. Sunlight can illuminate the conical metal foam layer through the transparent outer layer, the conical metal foam layer has the function of a heat absorber and converts light energy into heat energy, and the transparent outer layer has the function of a heat insulating layer and prevents heat in the heat absorber from being dissipated to the outside. The solar heat collector can effectively absorb solar radiation and fast store the energy and can be widely used for drying, food processing, household heat supplying , cooking and the like.

Owner:XI AN JIAOTONG UNIV

A kind of copper-clad alsic composite heat dissipation substrate and preparation method thereof

ActiveCN103515521BHigh thermal conductivityAdjustable expansion coefficientSemiconductor devicesSpinelThermal expansion

The invention discloses a copper-covered ALSiC composite radiating substrate which comprises an ALSiC substrate body and a copper layer attached to the ALSiC substrate body. A copper-aluminum spinel interface is formed between the copper layer and the ALSiC substrate body. The ALSiC composite radiation substrate is simple in structure, good in radiating performance, capable of solving the problem that the radiating substrate body is not matched with thermal expansion of a chip material, capable of preventing an LED chip packaged on the substrate body from being easily disengaged, capable of prolonging the service life of an LED and applicable to manufacturing of low-cost large-power LEDs.

Owner:惠州雷士光电科技有限公司 +1

Method for improving wear resistance of surface of iron-based powder metallurgy product by electron beam remelting

InactiveCN109967745ASolve the problem of low thermal conductivityEvenly heatedPowder metallurgyIron based alloy

The invention relates to a method for improving the wear resistance of a surface of an iron-based powder metallurgy product by electron beam remelting. The method comprises the following steps that firstly, iron-based alloy powder is pressed and sintered to prepare the iron-based powder metallurgy product; the sintered powder metallurgy product is fixed to a workbench, and a molding cavity is sealed and pumped to a high vacuum state; and high-energy electron beam scanning is performed on the surface of the product, so that the surface of the product is molten, and rapidly solidified. Accordingto the electron beam surface remelting iron-based powder metallurgy product prepared through the method, a martensite remelting layer structure with fine grains and uniform structures is formed aftercooled to the room temperature, and the hardness and the wear resistance of the product can be remarkably improved by the surface remelting layer.

Owner:常熟市华德粉末冶金有限公司

Intermediate heat conduction aluminum substrate manufacturing method

InactiveCN103607851ASolve the problem of low thermal conductivityTo satisfy the market's needsPrinted circuit manufactureHeat conductingEconomic benefits

The invention relates to an intermediate heat conduction aluminum substrate manufacturing method. The method includes the steps that a silane coupling agent is selected and used for performing surface treatment on filler A and filler B; a glue solution is prepared from resin, heat conduction filler, the filler A and the filler B, wherein in percentage by mass, the resin accounts for 60%, the heat conduction filler accounts for 40%, and the proportion between the filler A and the filler B is 1:5-1:20; 1080 glass cloth is used as a base body, the 1080 glass cloth is coated with the prepared glue solution, and drying is performed on the 1080 glass cloth to obtain a glue sheet; copper foil, the glue sheet and an aluminum plate are overlapped in sequence and formed through pressing of a press, and an intermediate heat conduction aluminum substrate is obtained. According to the intermediate heat conduction aluminum substrate manufacturing method, detection is performed according to the IPC-TM-650-2.4.13.1 standard, a plate material is immersed into tin at the temperature of 288 DEG C for 10-15 minutes, layering and bubbling are avoided, the problem of low heat-conducting property of the aluminum substrate is solved, market requirements are met, economic benefits are obvious, and the implementation effect is good.

Owner:TONGLING HAORONG ELECTRONICS TECH

A kind of stereotyped MOF base composite phase change material and its preparation method and application

ActiveCN110484213BHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsMetal foamThermal conductivity

The embodiment of the present invention relates to a shaped MOF-based composite phase change material and its preparation method and application. The shaped MOF-based composite phase-change material includes a MOF-based carrier and an organic phase-change core material loaded on the MOF-based carrier, wherein: The MOF-based carrier includes metal foam and MOF covered on the surface of the metal foam. The resulting shaped MOF-based composite phase-change material controls the shape and size of the metal foam so that the resulting shaped MOF-based composite phase-change material has the shape and size of the metal foam, and uses the metal foam as a part of the shaped MOF-based composite phase-change material, Since the metal foam itself has high thermal conductivity, it can also enhance the thermal conductivity of the composite phase change material.

Owner:SUZHOU ADVANCED MATERIALS CO LTD

Embedded vacuum scanning box titanium film cooling device

PendingCN112399696AFacilitate conductionSolve the problem of low thermal conductivityAcceleratorsCooling/ventilation/heating modificationsEngineeringCooling fluid

The invention discloses an embedded vacuum scanning box titanium film cooling device, and relates to the technical field of electron irradiation accelerators. The device comprises a heat conduction shell, a cooling liquid inlet pipe, a cooling liquid outlet pipe, a cooling liquid pipeline, a first branch pipeline and a second branch pipeline, wherein a beam passing square hole is formed in the middle part of the heat conduction shell, two cooling liquid pipelines are arranged in the heat conduction shell and located on the two sides of the beam passing square hole, one ends of the two coolingliquid pipelines are connected through the first branch pipeline, the other ends of the two cooling liquid pipelines are connected through the second branch pipeline, the cooling liquid inlet pipe isarranged at one end of the heat conduction shell, the cooling liquid inlet pipe is connected with the first branch pipeline, the cooling liquid outlet pipe is arranged at the other end of the heat conduction shell and connected with the second branch pipeline, a plurality of installation holes are evenly formed in the two sides of the heat conduction shell, and a titanium film heat conduction contact face is arranged on the upper surface of the heat conduction shell. The device is high in heat conduction efficiency, small in size, low in cost and convenient to use.

Owner:SHANGHAI SINOTEX HIGH ENERGY TECH

A kind of anti-scratch black heat-conducting ink and preparation method thereof

ActiveCN103725090BSolve the problem of easy to scratchMeet scratch resistance requirementsInksEpoxyHeat conducting

The invention discloses a scratch-resistant black heat transfer printing ink and a preparation method thereof. The printing ink comprises the following components in percent by weight: 25-35 percent of epoxy resin, 5-8 percent of phenolic resin, 3.5-5.0 percent of a curing agent, 45-60 percent of a heat conducting filling material, 10-12 percent of a coloring agent and 0.5-0.7 percent of an additive. The printing ink has a rigidity larger than 6 H after being roasted and pressed to meet the scratch-resistant requirement of Al-based copper-clad plate production and manufacturing, has the thermal conductivity reaching 1.5 W to facilitate the radiating of an Al-based copper-clad plate compared with an anodic oxidation film and a PET protecting film, and has a maximum bearing temperature of 230 DEG C and maximum pressure of 100 kg / cm<2>, and therefore, a novel method for using the heat transfer printing ink is found, the radiating function of the Al-based copper-clad plate is not affected while the aluminium surface is prevented from scratching. The heat transfer printing ink is a new measure for protecting the aluminium surface of the Al-based copper-clad plate.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

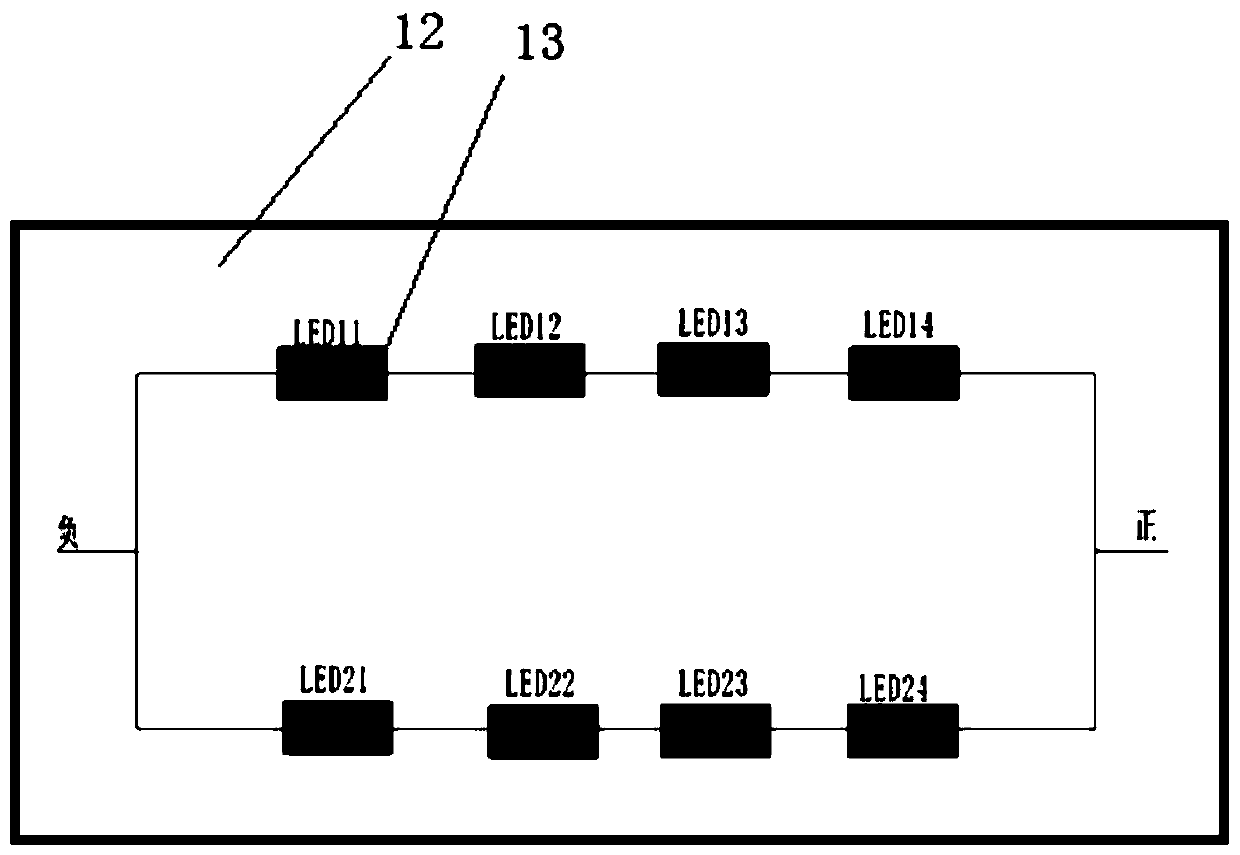

Aerospace high-power lamp

PendingCN110296345AGuaranteed tightnessGuaranteed thermal efficiencyHeat storage plantsLighting heating/cooling arrangementsLED lampAerospace

The invention discloses an aerospace high-power lamp. The aerospace high-power lamp comprises a protective window, condensing lenses, an LED lamp panel, a thermal dissipating plate, a sealing strip, athermal buffer medium and a shell; a thermal buffer medium filling area is arranged in the shell and filled with the thermal buffer medium; a sealing strip mounting groove is formed between the thermal buffer medium filling area and the inner wall of the shell, and a sealing strip is mounted in the sealing strip mounting groove; the thermal dissipating plate is arranged above the filling area andis in close fit with the thermal buffer medium; the LED lamp panel is mounted on the upper part of the thermal dissipating plate, and the condensing lenses are mounted on all LED lamps in the LED lamp panel; and the protective window is mounted at the top of the shell. The thermal buffer medium is added on the aerospace high-power lamp, a close frame type structure is adopted, and thus it is ensured that the lamp meets the using requirements of high-power lighting under high and low temperature environments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com