Composite shape-stabilized phase change material, preparation method and heat storage mortar prepared by using phase change material

A technology of phase change material and organic phase, which is applied in the field of heat storage mortar, can solve the problems of flammability of organic materials, poor compatibility, durability and safety of phase change heat storage mortar, and improve the flame retardancy , Improve the effect of heat storage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 30g of montmorillonite and 800ml of deionized water, mix and stir evenly, weigh 12g of cetyltrimethylammonium chloride, dissolve it in 160ml of deionized water, pour it into the montmorillonite suspension, and adjust the pH value to 6. Stir in a water bath at 60°C for 3 hours, filter, wash, precipitate, and dry to constant weight to obtain organic montmorillonite.

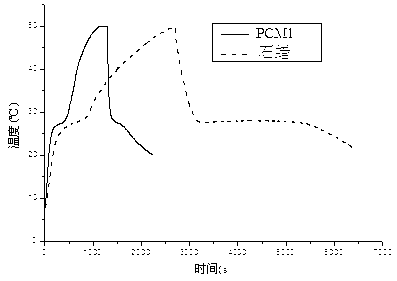

[0027] Weigh 50g of expanded graphite, 25g of organic montmorillonite, and 300g of paraffin, put them in a certain amount of ethanol solvent, ultrasonically treat for 6-8 hours, remove the organic solvent, dry and grind to obtain a powdery composite phase change material PCM1.

Embodiment 2

[0029] Weigh 15g of montmorillonite and 400ml of deionized water, mix and stir evenly, weigh 6g of cetyltrimethylammonium bromide and dissolve it in 80ml of deionized water, pour it into the montmorillonite suspension, and adjust the pH value to 6. Stir in a water bath at 60°C for 3 hours, filter, wash, precipitate, and dry to constant weight to obtain organic montmorillonite.

[0030] Weigh 52g of expanded graphite, 13g of organic montmorillonite, and 260g of decanoic acid, put them in a certain amount of ethanol solvent, ultrasonically treat for 6-8 hours, remove the organic solvent, dry and grind to obtain a powdery composite phase change material PCM2.

Embodiment 3

[0032] Weigh 15g of vermiculite and 400ml of deionized water, mix and stir evenly, weigh 6g of cetyltrimethylammonium chloride, dissolve it in 80ml of deionized water, pour it into the vermiculite suspension, and adjust the pH value to 6. Stir in a water bath at ℃ for 3 hours, then filter, wash, precipitate, and dry to constant weight to obtain vermiculite.

[0033] Weigh 52g of carbon black, 13g of organic vermiculite, and 260g of paraffin into a certain amount of ethanol solvent, ultrasonically treat for 6-8 hours, remove the organic solvent, dry and grind to obtain a powdery composite phase change material PCM3.

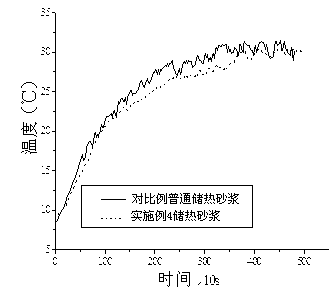

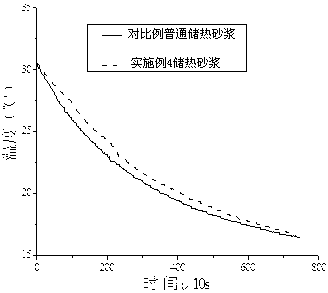

[0034] The composite shaped phase change material prepared in Examples 1-3 was compared with the paraffin phase change material commonly used in the market for performance testing, and the test results are shown in Table 1.

[0035] Examples of heat storage mortar:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com