Low-temperature phase-change composite material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

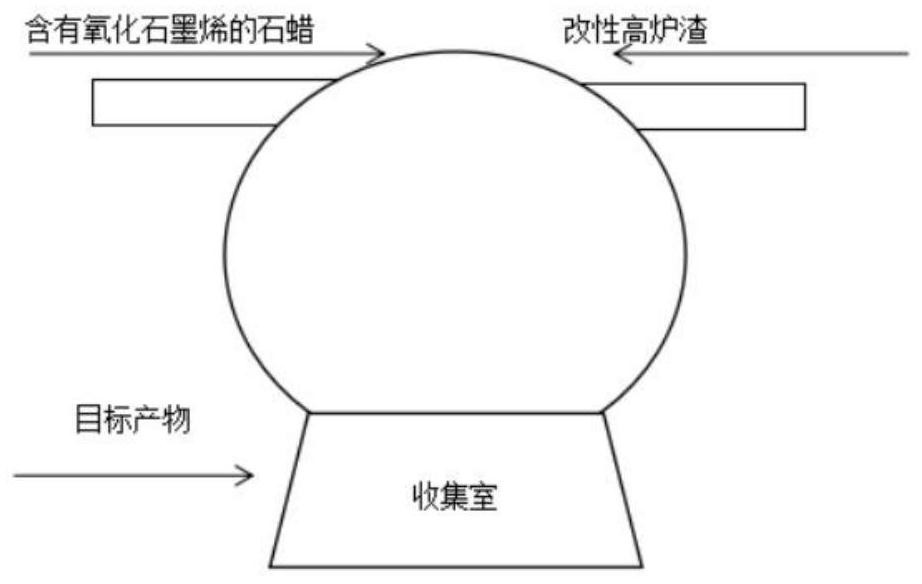

[0026] The invention provides a method for preparing a low-temperature phase-change composite material, comprising the following steps:

[0027] (1) modifying the blast furnace slag by using acid or lye to obtain modified blast furnace slag;

[0028] (2) paraffin, graphene oxide and dispersant are mixed to obtain paraffin containing graphene oxide;

[0029] (3) the modified blast furnace slag obtained in the step (1) is mixed with the paraffin wax containing graphene oxide obtained in the step (2), to obtain a low-temperature phase-change composite material;

[0030] There is no sequence for the preparation of the step (1) and step (2).

[0031] The invention uses acid or alkali to modify the blast furnace slag to obtain the modified blast furnace slag.

[0032] In the present invention, the particle size of the blast furnace slag is preferably >200 mesh, more preferably >230 mesh; the specific surface area of the blast furnace slag is preferably 1.93-2.37m 2 / g, more pre...

Embodiment 1

[0065] A method for preparing a low-temperature phase-change composite material, comprising the following steps:

[0066] (1) Grind the blast furnace slag and pass it through a 200-mesh sieve, add 3.5mol / L hydrochloric acid solution dropwise, modify it in a constant temperature water bath at 30°C for 2 hours, keep stirring during the modification process, and finally wash with water, filter and dry in sequence , to obtain modified blast furnace slag; the mass ratio of the volume of the hydrochloric acid solution to the blast furnace slag is 6mL: 1g;

[0067] (2) After drying 52# paraffin wax and graphene oxide in a vacuum drying oven, heat until the paraffin wax melts, mix the melted paraffin wax, graphene oxide and Span 80, use a magnetic stirrer for magnetic stirring, and use an ultrasonic Treat and carry out ultrasonic treatment, obtain the paraffin containing graphene oxide; The mass percentage of graphene oxide in the paraffin containing graphene oxide is 4%;

[0068] (3...

Embodiment 2

[0075] Use 6mol / L sodium hydroxide solution to modify the blast furnace slag, modify it in a 40°C constant temperature water bath for 3h, the temperature of the adsorption chamber is 50°C, and the paraffin wax containing graphene oxide is sprayed into the adsorption chamber The pressure is 0.1MPa, and the speed at which the paraffin wax containing graphene oxide is injected into the adsorption chamber is 60g / min; the pressure at which the modified blast furnace slag is injected into the adsorption chamber is 0.02MPa, and the modified blast furnace slag is injected into the adsorption chamber. The rate that enters adsorption chamber is preferably 200g / min; Other conditions are identical with embodiment 1.

[0076] The heat storage rate of the low-temperature phase-change composite material prepared in Example 2 is 8.90W / (m 2 ·K), the steady-state thermal conductivity is 0.45W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com