A medium-high temperature nanocomposite metal phase change heat storage material and its preparation method

A heat storage material and nano-composite technology, applied in the direction of heat exchange materials, metal processing equipment, chemical instruments and methods, etc., can solve the problems of low sensible heat density, environmental pollution, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

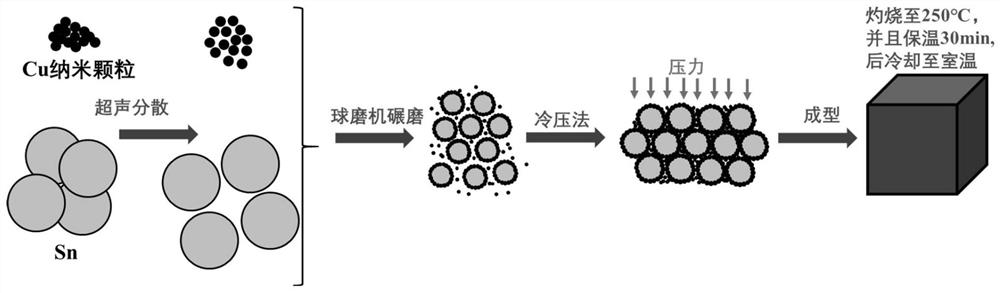

[0030] Such as figure 1 As shown, a method for preparing a medium-high temperature nanocomposite metal phase-change heat storage material, comprising the following steps:

[0031] (1) Put nano-copper powder with a particle size of 50nm and ordinary tin powder with a particle size of 74 μm into an ultrasonic disperser for 60 minutes;

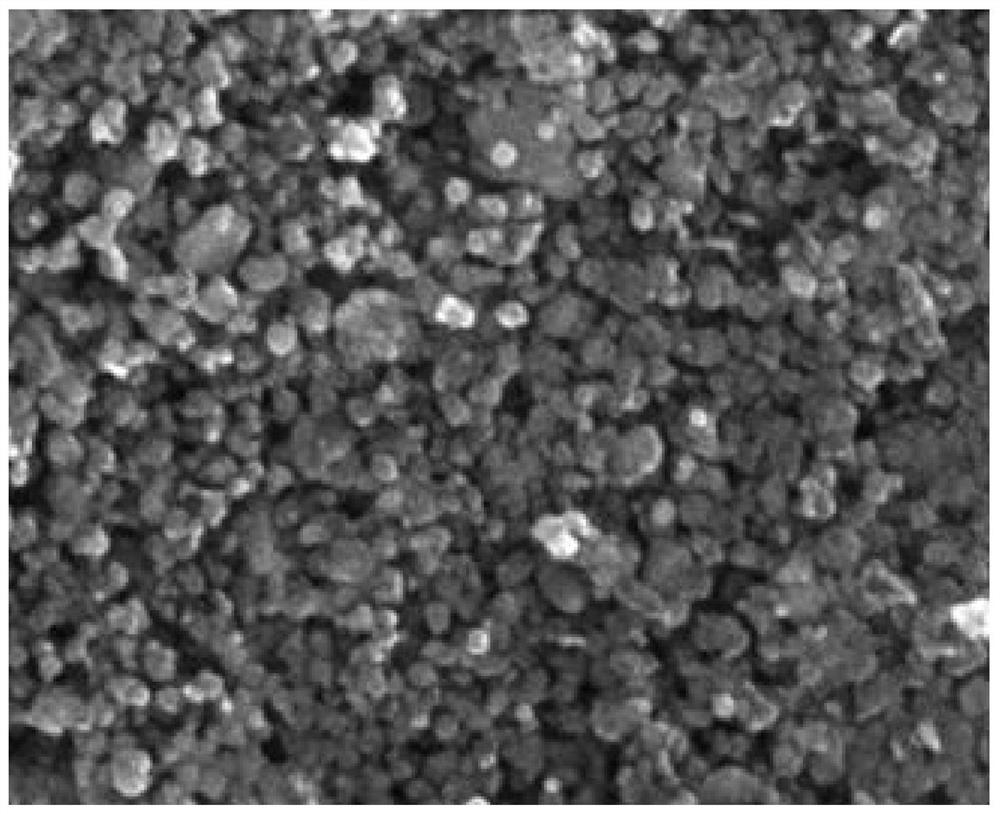

[0032] (2) Put the nano-copper powder and ordinary tin powder into the ball mill respectively, the mass ratio between the nano-copper powder and the ordinary tin powder is 1:1; the ball mill first ball mills at a speed of 200r / min for 60min, and then at 100r / min Speed ball milling for 60min, after mixing uniformly, copper-tin mixed particles were obtained;

[0033] (3) Compressing the copper-tin mixed particles with a pressure of 136 MPa by cold pressing method to obtain the first product of copper-tin composite phase change thermal storage material;

[0034] (4) Put the primary product of copper-tin composite phase change heat storage materi...

Embodiment 2

[0037] Such as figure 1 As shown, a method for preparing a medium-high temperature nanocomposite metal phase-change heat storage material, comprising the following steps:

[0038] (1) Put the nano-copper powder with a particle size of 50nm and the ordinary tin powder with a particle size of 74 μm into an ultrasonic disperser for 50 minutes;

[0039] (2) Put the nano-copper powder and ordinary tin powder into the ball mill respectively, the mass ratio between the nano-copper powder and the ordinary tin powder is 1:4; the ball mill first ball mills at a speed of 100r / min for 70min, and then at 150r / min Speed ball milling for 50min, mixed uniformly to obtain copper-tin mixed particles;

[0040] (3) Compressing the copper-tin mixed particles with a pressure of 100 MPa by cold pressing method to obtain the first product of the copper-tin composite phase change thermal storage material;

[0041] (4) Put the primary product of copper-tin composite phase change heat storage materi...

Embodiment 3

[0044] Such as figure 1 As shown, a method for preparing a medium-high temperature nanocomposite metal phase-change heat storage material, comprising the following steps:

[0045] (1) Put nano-copper powder with a particle size of 50nm and ordinary tin powder with a particle size of 74 μm into an ultrasonic disperser for 70 minutes;

[0046] (2) Put the nano-copper powder and ordinary tin powder into the ball mill respectively. The mass ratio between the nano-copper powder and the ordinary tin powder is 3:7; the ball mill first ball mills at a speed of 300r / min for 50min, and then at 50r / min Speed ball milling for 70min, mixed uniformly to obtain copper-tin mixed particles;

[0047] (3) Compressing the copper-tin mixed particles with a pressure of 500 MPa by cold pressing method to obtain the first product of the copper-tin composite phase change thermal storage material;

[0048] (4) Put the primary product of copper-tin composite phase change heat storage material into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com