Metal hydride hydrogen storage tank based on phase change heat storage and solid-gas coupling hydrogen storage system

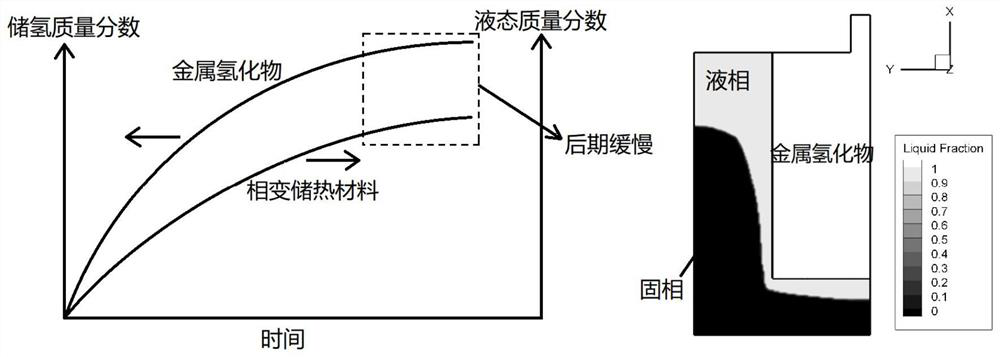

A technology for hydrogen storage tanks and hydrides, which is applied to fixed-capacity gas storage tanks, container discharge methods, and equipment loaded into pressure vessels, etc., can solve the problems of reduced hydrogen storage rate, limited scope of application, and low thermal conductivity. , to achieve the effect of increasing hydrogen storage and heat storage rates, reducing parasitic power loss, and increasing volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

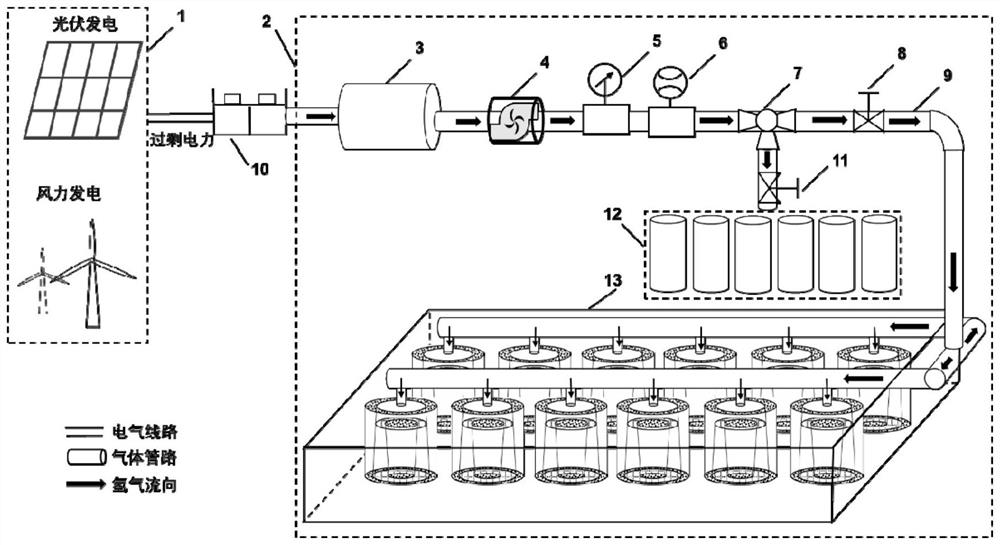

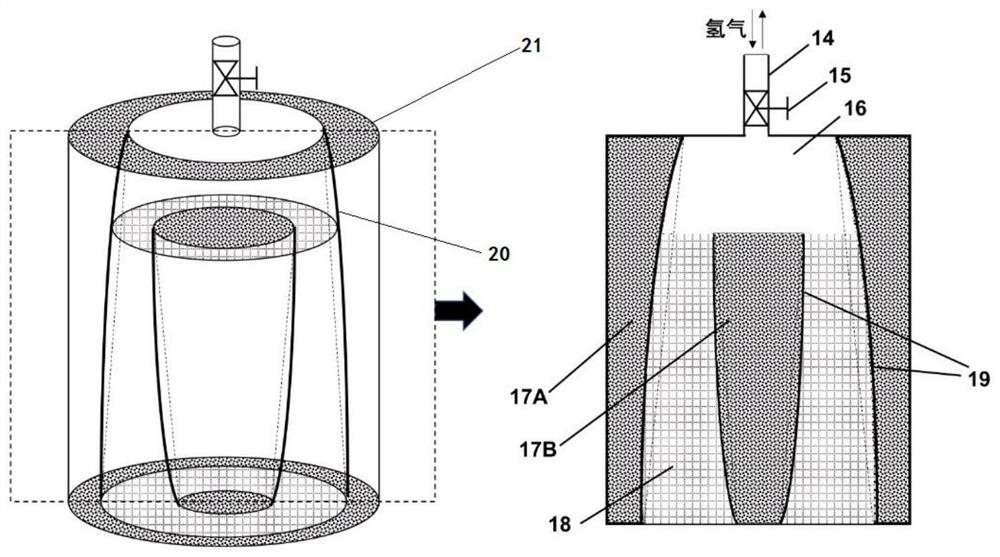

[0036] This embodiment provides a solid-state hydrogen storage-gaseous hydrogen storage coupled hydrogen storage system, and the schematic structural diagram of the hydrogen storage system is shown in the appendix figure 2 As shown, the hydrogen storage system is located downstream of the renewable energy power generation system (1), and is used to store the surplus power of the power generation system in the form of hydrogen, and the surplus power is converted into water under the action of the electrolyzer (10). hydrogen. The hydrogen generated by the electrolyzer is transported to the gaseous hydrogen storage tank (12) and the solid hydrogen storage tank (13) through the main pipeline (9). According to the flow direction of the hydrogen, a hydrogen buffer tank (3) is arranged on the main pipeline (9) in turn , hydrogen pump (4), pressure sensor (5), flow meter (6), three-way valve (7), solenoid valve (8); between the three-way valve (7) and the gaseous hydrogen storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com