High-thermal-conductivity and low-dielectric composite material and preparation method thereof

A composite material and low-dielectric technology, which is applied in the preparation of low-dielectric composite materials, low-dielectric composite materials, and high thermal conductivity fields, can solve problems such as low thermal conductivity and poor processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the high thermal conductivity, low dielectric composite material comprises the following steps:

[0034] Step S1: providing boron nitride nanosheet dispersion and polytetrafluoroethylene dispersion;

[0035] Step S2: mixing the boron nitride nanosheet dispersion and polytetrafluoroethylene dispersion to obtain a mixed dispersion;

[0036] Step S3: drying the mixed dispersion to obtain a mixed slurry;

[0037] Step S4: performing hot rolling treatment on the mixed slurry to obtain a mixed film; and

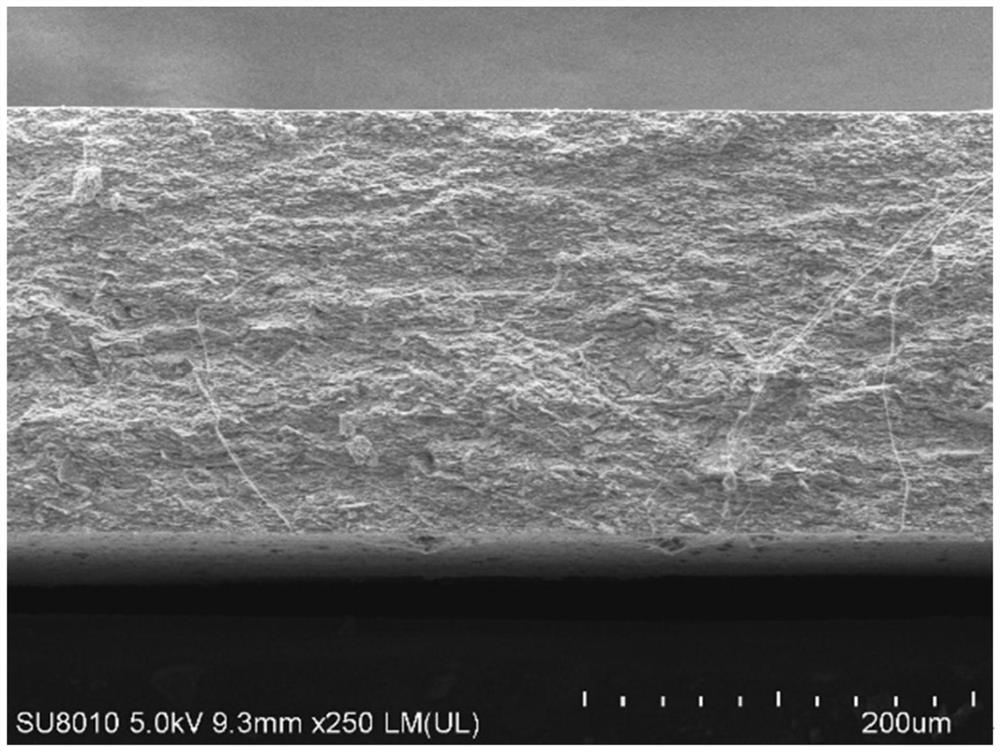

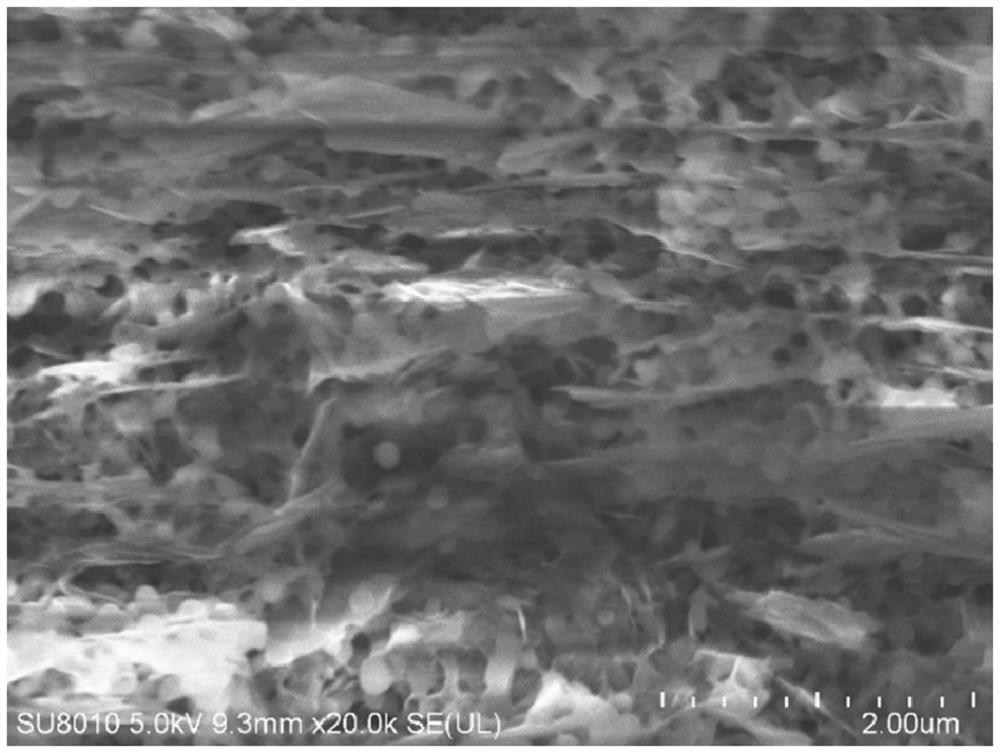

[0038] Step S5: Sintering the mixed film to obtain a high thermal conductivity, low dielectric composite material, wherein the high thermal conductivity, low dielectric composite material includes polytetrafluoroethylene and polytetrafluoroethylene distributed in the polytetrafluoroethylene Boron nitride nanosheets, the boron nitride nanosheets are overlapped end to end to form several layers of continuous heat conduction paths (refer to figure ...

Embodiment 1

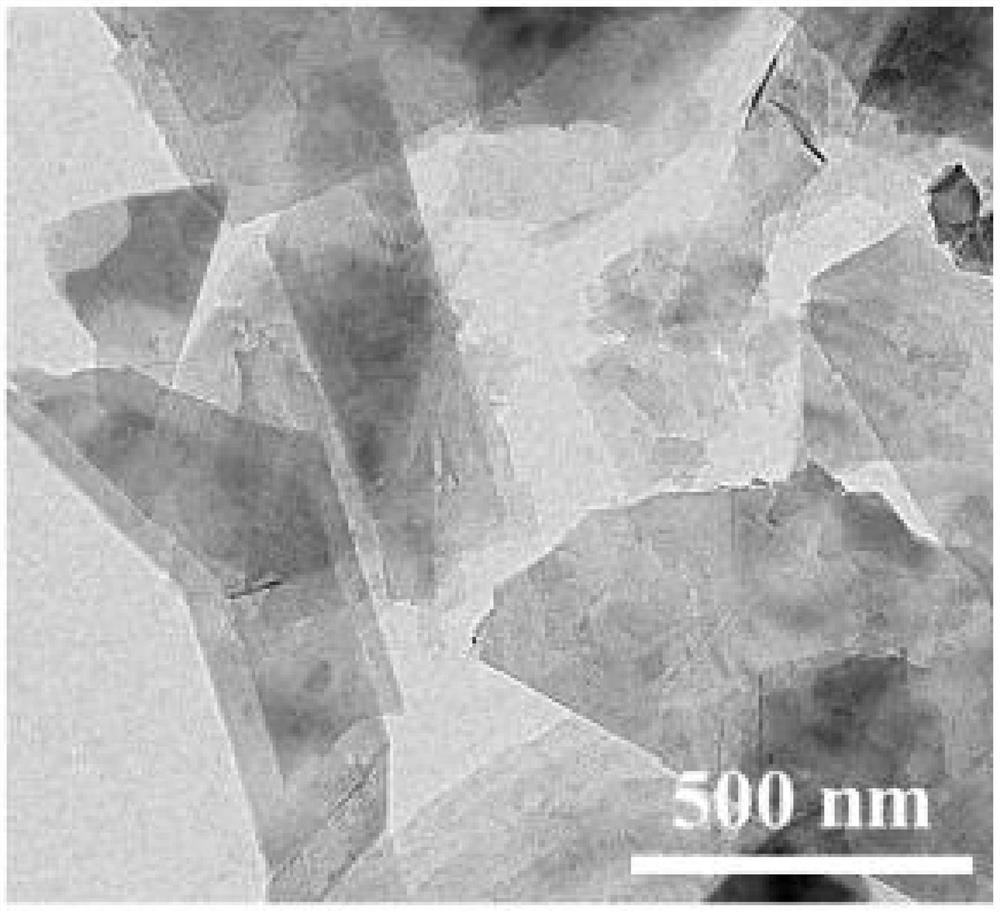

[0074] Provide a boron nitride nanosheet dispersion with a concentration of 2 mg / mL, wherein the boron nitride nanosheet dispersion contains deionized water and boron nitride nanosheets with a sheet diameter of 0.2-1.0 μm;

[0075] Provide a polytetrafluoroethylene dispersion with a solid content of 60% by weight;

[0076] Slowly drop 0.5mL polytetrafluoroethylene dispersion into 400mL boron nitride nanosheet dispersion, and magnetically stir for 30 minutes to obtain a mixed dispersion, wherein, in the mixed dispersion, the proportion of the boron nitride nanosheets is 10wt%;

[0077] The mixed dispersion was placed in an oven at 80° C. for 1 hour to obtain a mixed slurry with a water content of 35 wt %;

[0078] Kneading the mixed slurry, so that the boron nitride nanosheets and polytetrafluoroethylene nanoparticles in the mixed slurry are uniformly mixed;

[0079] The kneaded mixed slurry was subjected to hot rolling treatment to obtain a mixed film, wherein, during the ho...

Embodiment 2

[0082] Provide a boron nitride nanosheet dispersion with a concentration of 2 mg / mL, wherein the boron nitride nanosheet dispersion contains deionized water and boron nitride nanosheets with a sheet diameter of 0.2-1.0 μm;

[0083] Provide a polytetrafluoroethylene dispersion with a solid content of 60% by weight;

[0084] Slowly drop 1mL of the polytetrafluoroethylene dispersion into 400mL of the boron nitride nanosheet dispersion, and stir magnetically for 30 minutes to obtain a mixed dispersion, wherein, in the mixed dispersion, the proportion of the boron nitride nanosheets is 20wt%;

[0085] The mixed dispersion was placed in an oven at 80° C. for 1 hour to obtain a mixed slurry with a water content of 35 wt %;

[0086] Kneading the mixed slurry, so that the boron nitride nanosheets and polytetrafluoroethylene nanoparticles in the mixed slurry are uniformly mixed;

[0087] The kneaded mixed slurry was subjected to hot rolling treatment to obtain a mixed film, wherein, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com