A kind of stereotyped MOF base composite phase change material and its preparation method and application

A technology of composite phase change material and core material, which is applied in the direction of heat exchange materials, chemical instruments and methods to achieve the effects of good thermal conductivity, enhanced thermal conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

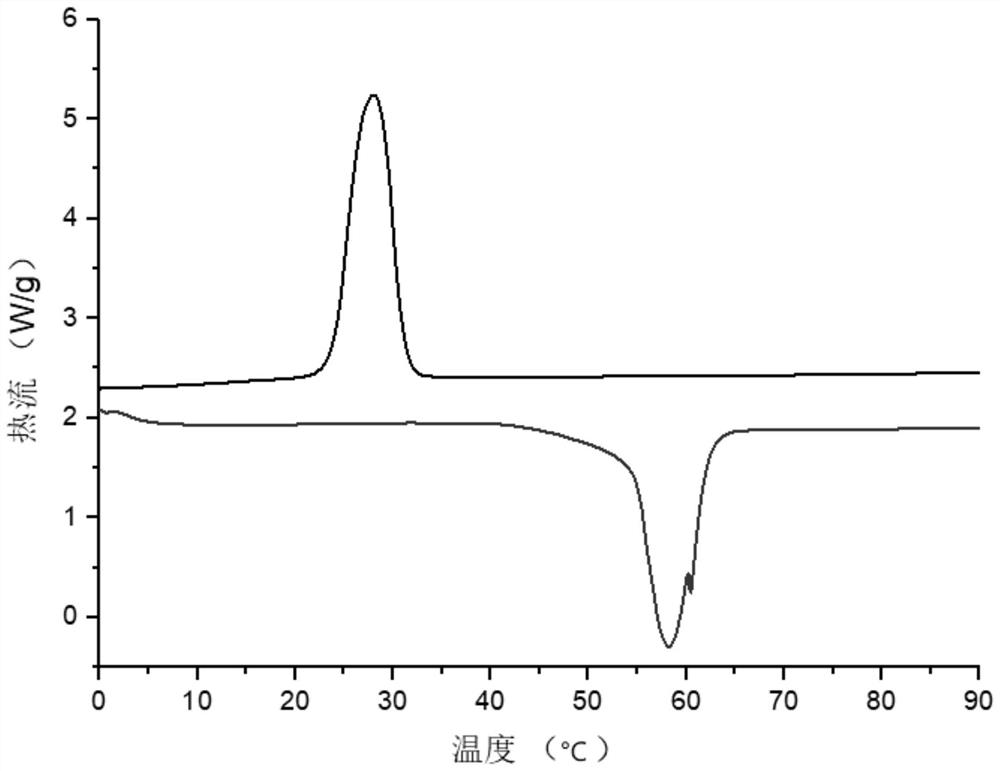

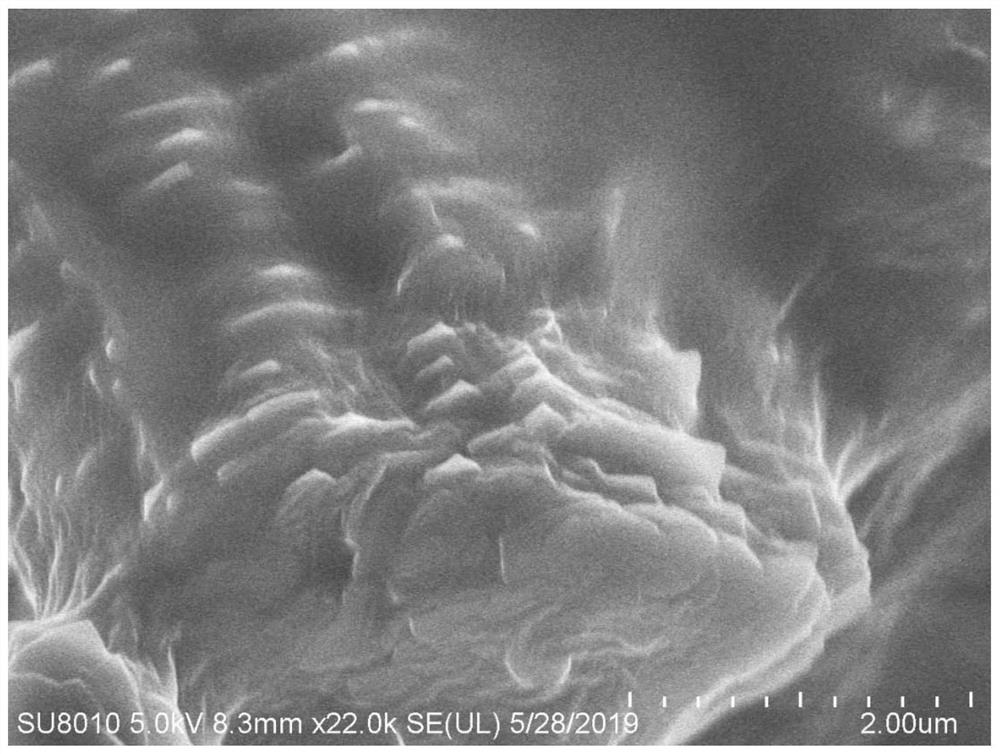

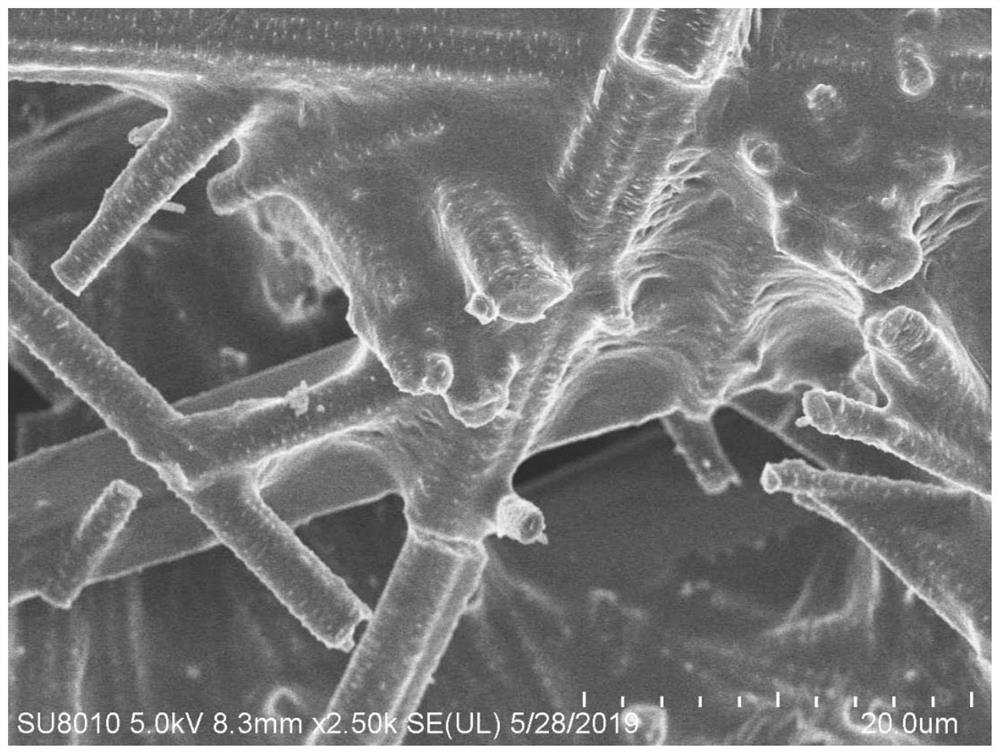

[0048] Cu-BTC based composite phase change material

[0049] 1) Select a 500-mesh copper sieve with a volume of 2 cm × 2 cm × 1 mm, immerse the copper sieve in acetone, methanol, and deionized water for 30 min respectively, and then dry in a blast oven at 60° C. to obtain a substrate for Cu-BTC growth. ;

[0050] 2) 7.021g of copper nitrate and 3.063g of trimesic acid are fully dissolved in the mixed solution of 25mL of water and 25mL of ethanol, vigorously stirred for 30min at room temperature to obtain a homogeneous solution, then moved into the reactor, Put it into an oven to react at 95°C for 15h. After the reaction product was washed by centrifugation, it was put into an oven and dried at 80°C for 8h to obtain Cu-BTC. The dried Cu-BTC was dissolved in water to obtain a Cu-BTC mother solution. The molar ratio of the dried Cu-BTC powder and water was 1:25.

[0051] 3) Preheat the copper sieve in step 1) at 100°C for 10 min, and at this temperature, drop the Cu-BTC mother ...

Embodiment example 2

[0055] Cr-MIL-101-NH 2 matrix composite phase change material

[0056] 1) Select a 500-mesh copper sieve with a volume of 2cm × 2cm × 1mm, immerse the copper sieve in acetone, methanol, and deionized water for 30 minutes in sequence, and dry at 60°C in a blast oven each time to obtain Cr-MIL-101- NH 2 growing substrate;

[0057] 2) Fully dissolve 3.2 g of 2-aminoterephthalic acid and 3.2 g of chromium nitrate nonahydrate in 60 mL of deionized water, add 0.8 g of sodium hydroxide and stir vigorously for 30 min at room temperature to obtain a uniform solution, then It was moved into the reaction kettle and put into an oven for 12 hours at 150°C. The reaction product was washed by centrifugation, and then placed in an oven and dried at 80°C for 8 hours to obtain Cr-MIL-101-NH. 2 , the dried Cr-MIL-101-NH 2 Dissolved in water to get Cr-MIL-101-NH 2 Mother liquor, in which the dried Cr-MIL-101-NH 2 The molar ratio of powder and water is 1:25.

[0058] 3) Preheat the copper s...

Embodiment example 3

[0061] MOF-5 based composite phase change material

[0062] 1) Select a 500-mesh copper sieve with a volume of 2cm×2cm×1mm, immerse the copper sieve in acetone, methanol, and deionized water for 30 minutes respectively, and then dry it in a blast oven at 60°C to obtain a substrate for MOF-5 growth. ;

[0063] 2) Fully dissolve 0.69g of terephthalic acid and 3.41g of zinc nitrate hexahydrate in 100mL DMF, stir vigorously for 30min at room temperature to obtain a uniform solution, then move it into a reaction kettle, put it in an oven for 100 The reaction was carried out at ℃ for 18 h, the reaction product was washed by centrifugation, and then put into an oven and dried at 80 ℃ for 8 h to obtain MOF-5. The dried MOF-5 was dissolved in water to obtain the MOF-5 mother liquor, wherein the dried MOF-5 5 The molar ratio of powder and water is 1:25.

[0064] 3) Preheat the copper sieve treated in step 1) at 100°C for 10 min, and at this temperature, drop the MOF-5 mother liquor pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com