Bipolar plate of proton exchange membrane fuel cell with uniform thermal conductivity

A proton exchange membrane, fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of increasing battery weight, low thermal conductivity, reducing fluid pressure drop, etc., to solve the problem of heavier mass and low thermal conductivity , the effect of reducing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

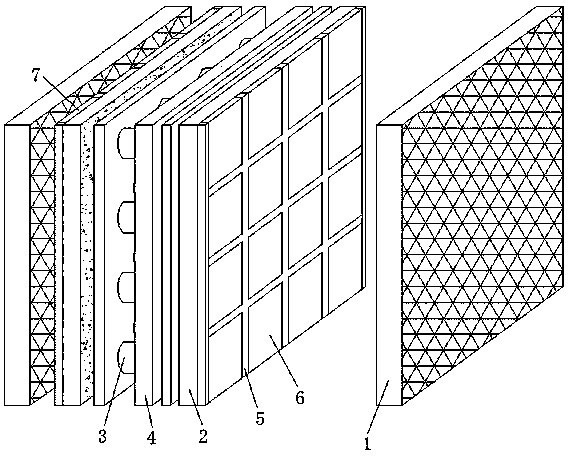

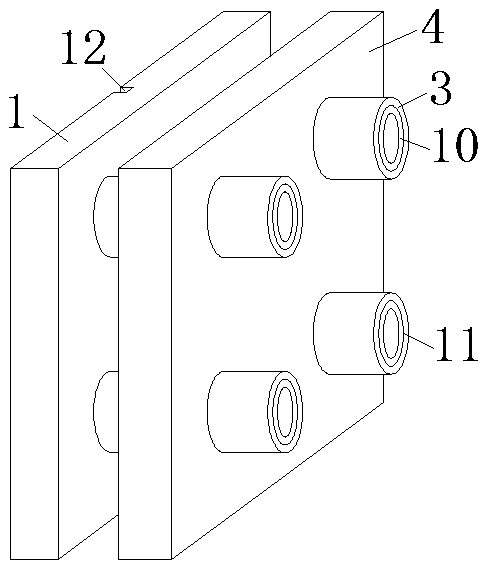

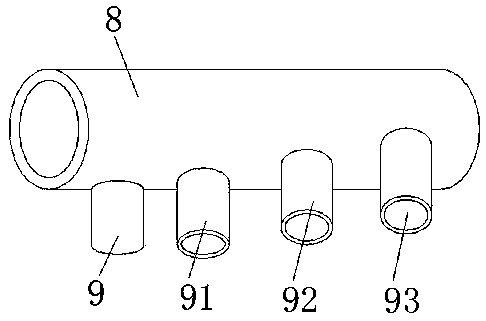

[0036] refer to Figure 1-5 , a proton exchange membrane fuel cell bipolar plate with uniform thermal conductivity, such as figure 1 As shown, it includes a diffusion layer 1 and a catalytic layer 2, and the opposite surfaces of the two catalytic layers 2 are fixedly connected with a proton exchange membrane 4, and the opposite surfaces of the two catalytic layers 2 are respectively fixedly connected with the opposite surfaces of the two diffusion layers 1 , the opposite surface of the catalytic layer 2 is fixedly connected with a phase-change heat-conducting insulating tube 3, the surface of the phase-change heat-conducting insulating tube 3 runs through the proton exchange membrane 4, and a plurality of phase-change heat-conducting insulating tubes 3 are distributed on the catalytic layer 2 in a rectangular array s surface.

[0037] like figure 2 As shown, by setting the opposite surfaces of the catalytic layer 2 to be fixedly connected with the phase-change heat conducti...

Embodiment 2

[0045] refer to Figure 1-5 , a proton exchange membrane fuel cell bipolar plate with uniform thermal conductivity, such as figure 1 As shown, it includes a diffusion layer 1 and a catalytic layer 2, and the opposite surfaces of the two catalytic layers 2 are fixedly connected with a proton exchange membrane 4, and the opposite surfaces of the two catalytic layers 2 are respectively fixedly connected with the opposite surfaces of the two diffusion layers 1 , the opposite surface of the catalytic layer 2 is fixedly connected with a phase-change heat-conducting insulating tube 3, the surface of the phase-change heat-conducting insulating tube 3 runs through the proton exchange membrane 4, and a plurality of phase-change heat-conducting insulating tubes 3 are distributed on the catalytic layer 2 in a rectangular array s surface.

[0046] like figure 2 As shown, by setting the opposite surfaces of the catalytic layer 2 to be fixedly connected with the phase-change heat conducti...

Embodiment 3

[0054] refer to Figure 1-5 , a proton exchange membrane fuel cell bipolar plate with uniform thermal conductivity, such as figure 1 As shown, it includes a diffusion layer 1 and a catalytic layer 2, and the opposite surfaces of the two catalytic layers 2 are fixedly connected with a proton exchange membrane 4, and the opposite surfaces of the two catalytic layers 2 are respectively fixedly connected with the opposite surfaces of the two diffusion layers 1 , the opposite surface of the catalytic layer 2 is fixedly connected with a phase-change heat-conducting insulating tube 3, the surface of the phase-change heat-conducting insulating tube 3 runs through the proton exchange membrane 4, and a plurality of phase-change heat-conducting insulating tubes 3 are distributed on the catalytic layer 2 in a rectangular array s surface.

[0055] like figure 2 As shown, by setting the opposite surfaces of the catalytic layer 2 to be fixedly connected with the phase-change heat conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com